Exhaust heat recovery device

a heat recovery device and exhaust heat technology, applied in indirect heat exchangers, machines/engines, lighting and heating apparatus, etc., can solve the problems of high manufacturing cost, thermal stress, and holes in the bellows, and achieve the effect of preventing the occurrence of holes and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0022]A first embodiment of the invention will be described with reference to FIG. 1. An exhaust heat recovery device of this embodiment is adapted to recover exhaust heat of an exhaust gas from an exhaust system of an engine (e.g., internal combustion engine) of a vehicle, and to use the exhaust heat for promotion of warning or the like.

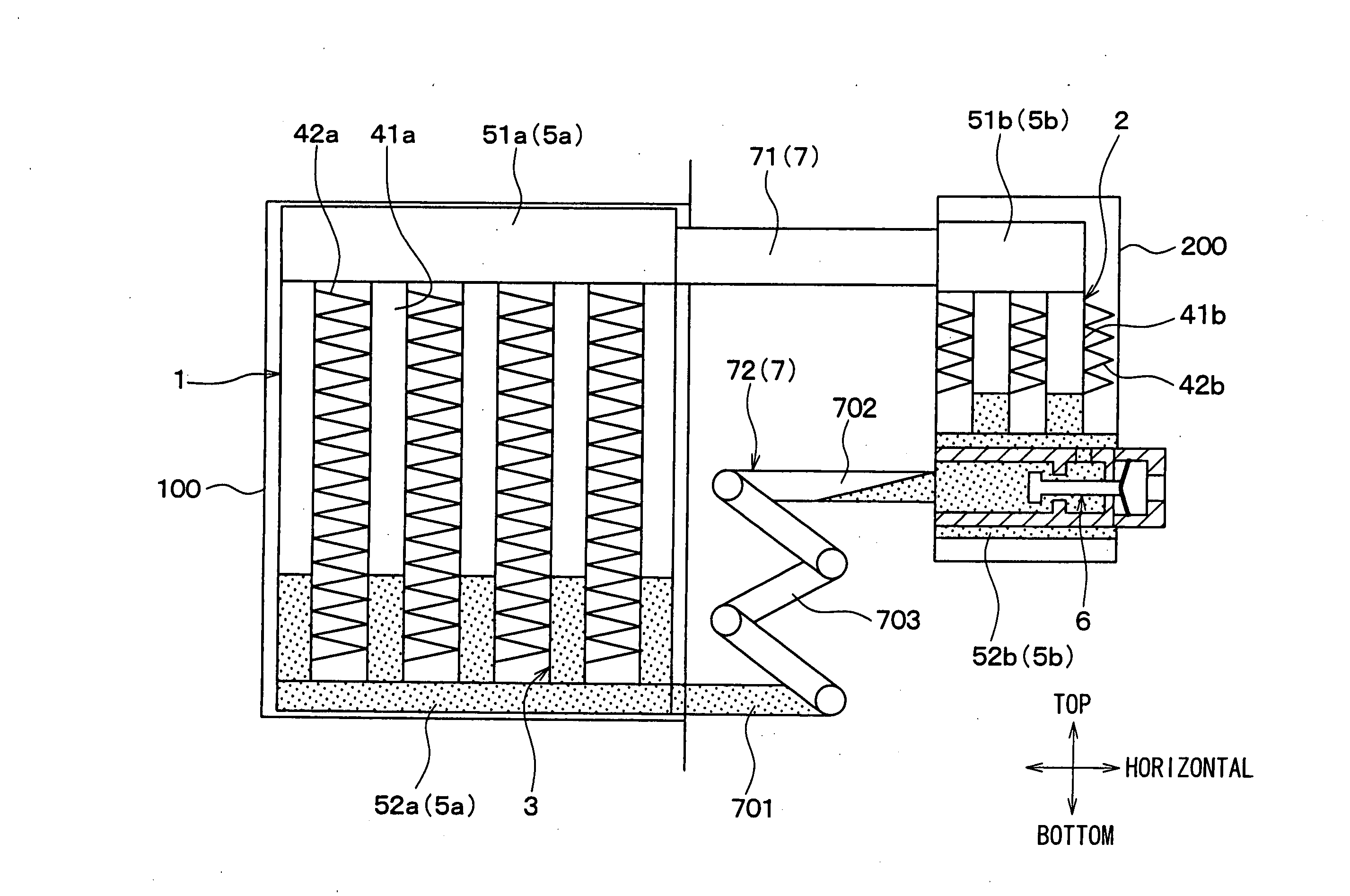

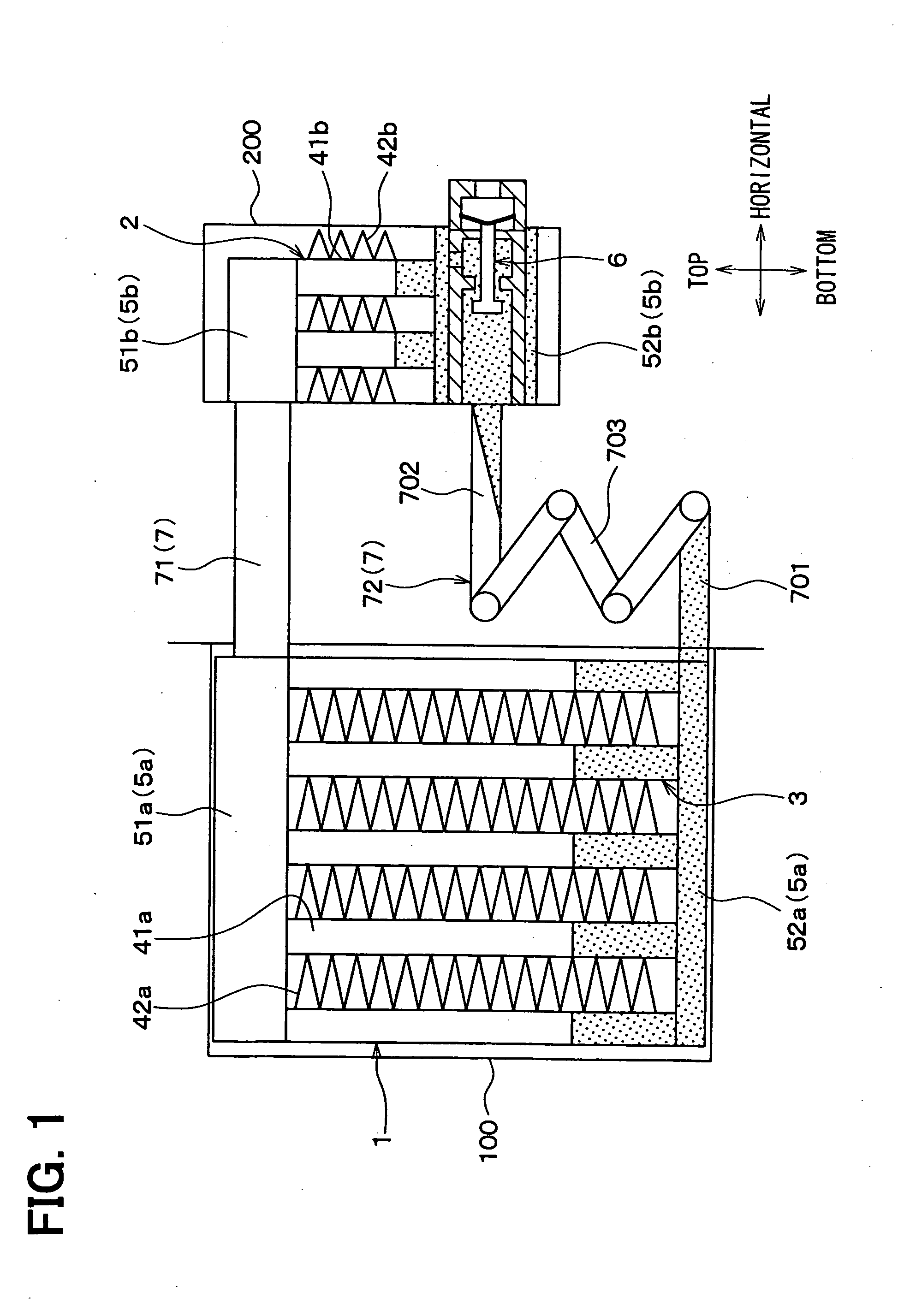

[0023]FIG. 1 is a schematic sectional view showing an example of the exhaust heat recovery device of the first embodiment. As shown in FIG. 1, the exhaust heat recovery device of this embodiment includes an evaporator 1 and a condenser 2. The evaporator 1 and the condenser 2 are connected to each other to form a loop-type heat pipe 3.

[0024]The heat pipe 3 is provided with an sealing portion (not shown), from which the heat pipe 3 is evacuated to vacuum (decompressed). After being filled with a working medium, the sealing portion is sealed. The working fluid in use is water, for example. The working fluid for use may include alcohol, fluorocarbon, fl...

second embodiment

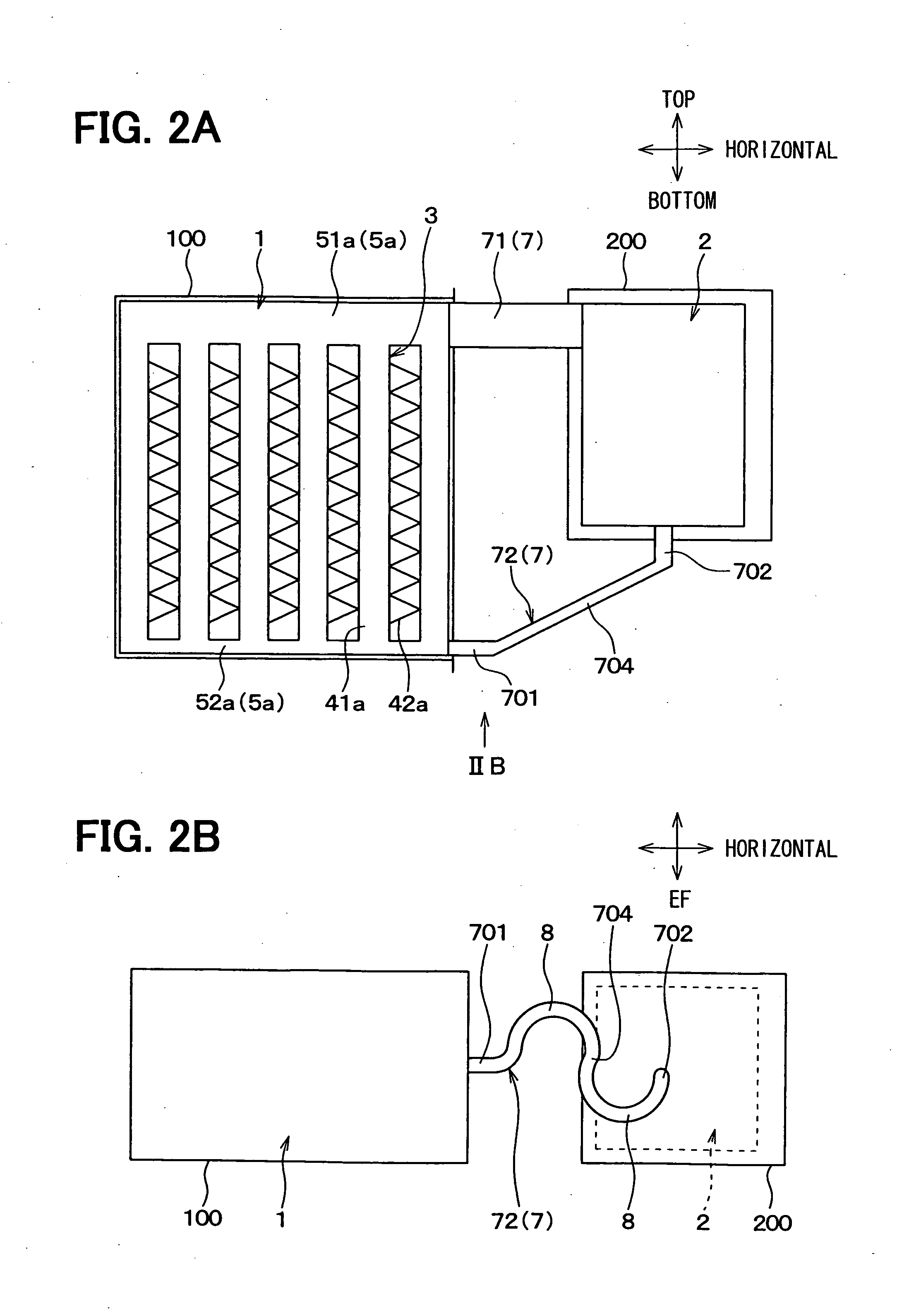

[0040]Now, a second embodiment of the invention will be described below based on FIGS. 2A and 2B. The elements having the same functions as those of the first embodiment will be designated by the same reference numerals, and a description thereof will be described below.

[0041]FIG. 2A is a sectional view showing an exhaust heat recovery device according to the second embodiment, and FIG. 2B is a diagram viewed along an arrow IIB in FIG. 2A. In FIGS. 2A and 2B, representation of the detailed structure of the condenser 2 will be omitted.

[0042]As shown in FIGS. 2A and 2B, in the second embodiment, a condensation side connection portion 72 includes a lower member 701 having one end connected to the second evaporation side header 52a and extending substantially in the horizontal direction toward the condenser 2, and an upper member 702 having one end connected to the lower end of the second condensation side header (not shown) of the condenser 2 and extending substantially in the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com