Addition-amount controller for exhaust gas purifying agent and exhaust emission control system

a technology of exhaust gas purifying agent and controller, which is applied in the direction of exhaust treatment electric control, machines/engines, separation processes, etc., can solve problems such as deterioration of emission characteristics, and achieve the effects of improving exhaust gas purification capacity, reducing activation temperature, and increasing the amount of stored nh3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

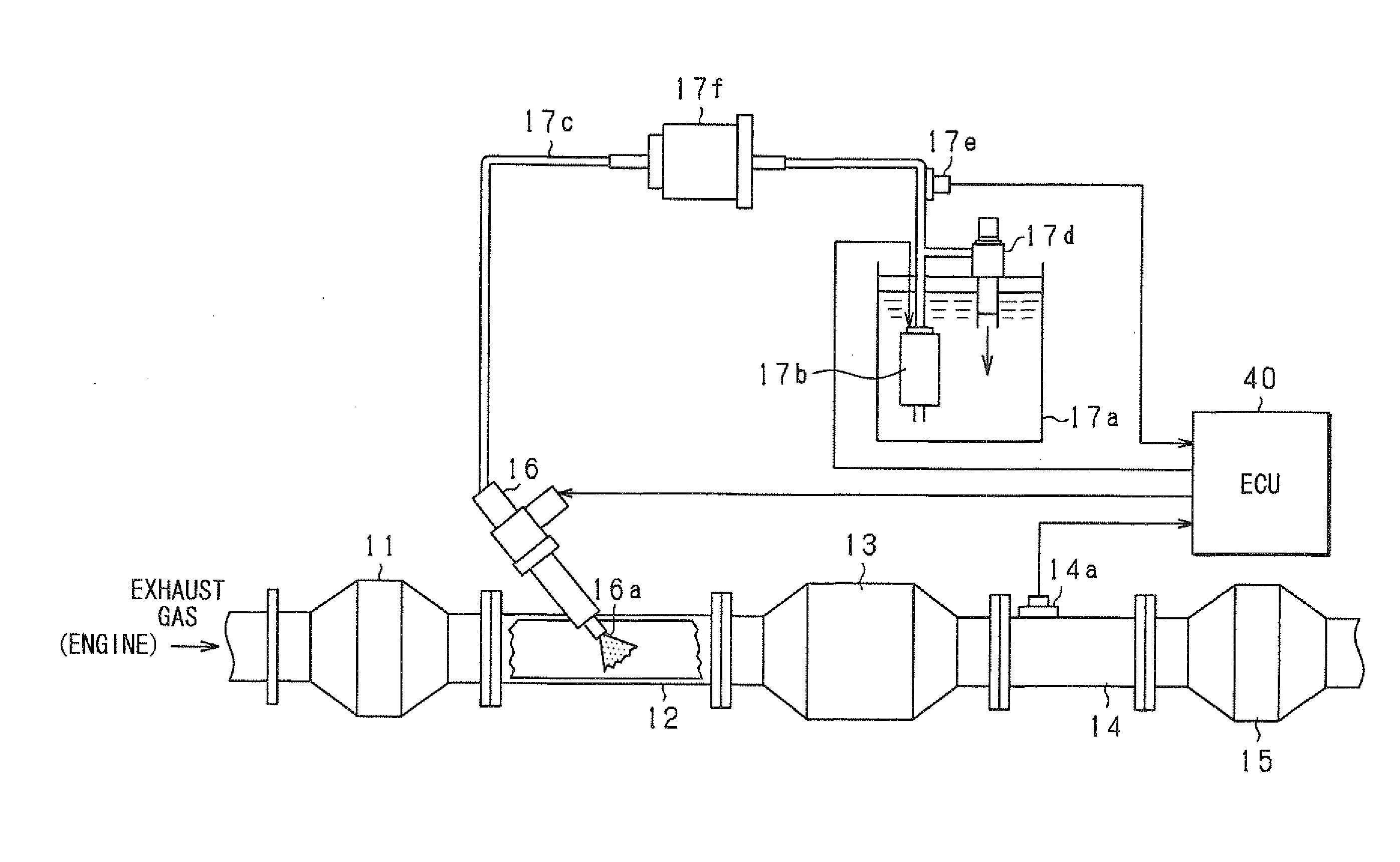

[0031]An addition-amount controller for an exhaust gas purifying agent and an exhaust emission control system according to one embodiment of the invention will be described below with reference to the accompanying drawings. The exhaust emission control system of this embodiment has the basic structure used in a general urea-SCR (selective reduction) system, as an example. With the structure shown in FIG. 1, NH3 (ammonia) generated from a urea ((NH2)2CO) aqueous solution (hereinafter referred to as a urea water) reduces (purifies) NOx in exhaust gas.

[0032]Referring to FIG. 1, the structure of the exhaust emission control system will be described in detail below. FIG. 1 is a diagram schematically showing the structure of a urea-SCR system (exhaust gas purification device) according to this embodiment.

[0033]As shown in FIG. 1, this system is adapted to purify exhaust gas emitted from a diesel engine (exhaust gas generating source) mounted on, for example, a four-wheeled vehicle (not sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| rotation speed | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com