Substrate treatment method for portion to be coated

a technology of substrate and coating, applied in the direction of metal-working equipment, manufacturing tools, abrasives, etc., can solve the problems of uneven film thickness and formation of thin portions, damage to coatings, and impairing the coatings' function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0106]Next, the results of tests for comparison of workpieces subjected to substrate treatment by the method of the present invention, as well as those after coatings were formed thereon, with workpieces subjected to substrate treatment by a known blasting method, as well as those after coatings were formed thereon, will be shown.

Examination of Embedded Abrasive Grains

[0107]Next, the results of examination of embedded abrasive grains on workpieces formed of various materials and subjected to different substrate treatments, including samples subjected to substrate treatment by the method of the present invention, untreated samples, and samples subjected to substrate treatment by a typical blasting method, will be shown below.

[0108]Cold-Rolled Steel Sheet (SPCC) Treatment Test

[0109]Processing Conditions

example

[0110]The substrate treatment method (Example) of the present invention was performed under the conditions shown in Table 2 below.

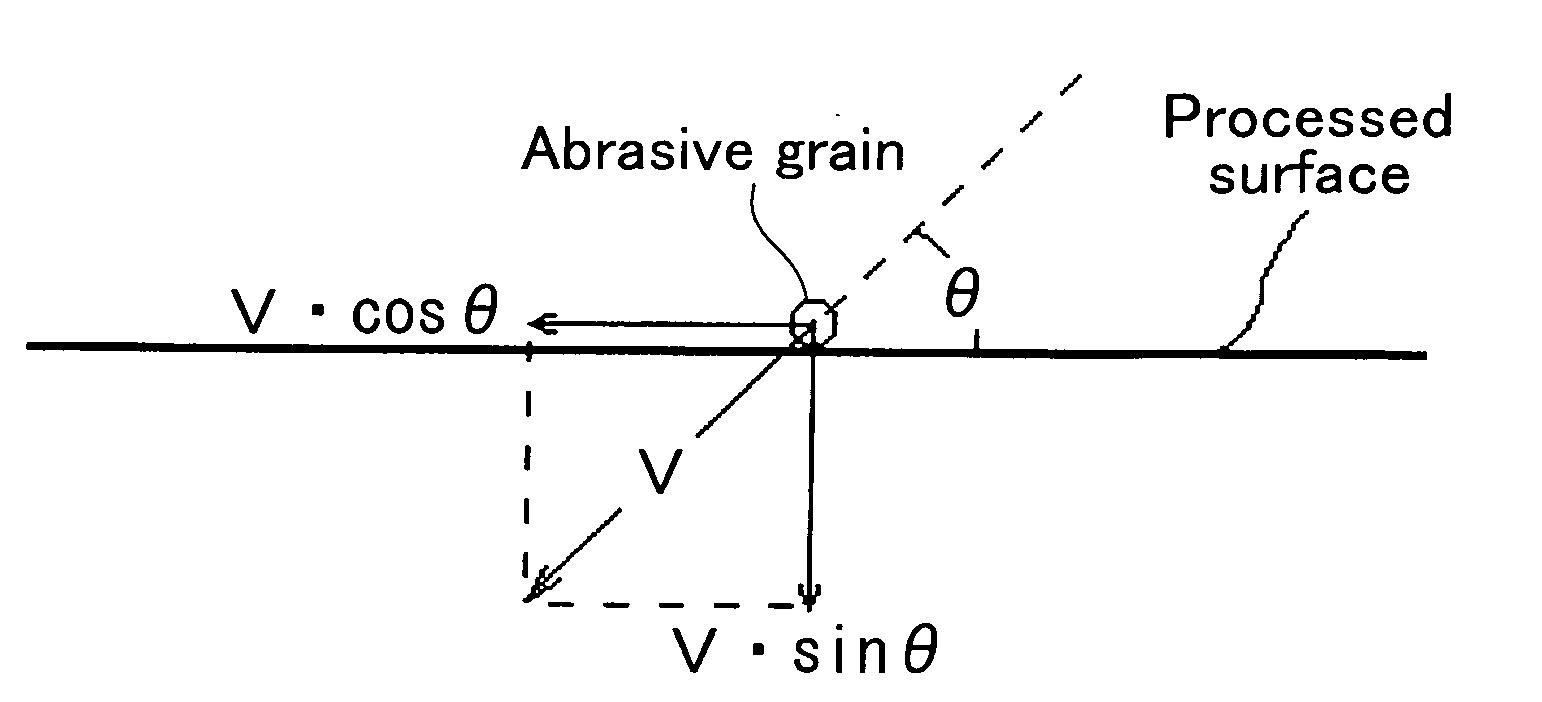

TABLE 2Processing Conditions for Substrate Treatment under the present Invention (Example 1-4)Example 1Example 2Example 3Example 4WorkpieceCold-RolledAlloy Tool SteelCemented CarbideAluminumSteel Sheet(SKD11)(KHO3) manufactured by(A1100)(SPCC)Sumitomo Electric Industries, Ltd.Blasting“FDQ-SR”“SG-SR”“SG-SR”“LDQ-SR”MachineFuji Mfng.Ejection MethodDirect-pressureGravityGravityDirect-pressure (Blower)Compressed airCompressorCompressorCompressorBlowerSupply methodCondition Of EjectionPressure (MPa) 0.3 0.2 0.5 0.02Ejection 705010050distance(mm)Incident angle θ° 3045 6075Nozzle-tip 810 610diameter(mm)Ejection materialAbrasive grains compounded and dispersed in the base materialElastic abrasiveAverage650353501000 grain sizeMinimum (μm)50020200800 Maximum (μm)800505001200 Base materialRubberAbrasive grains“Fujilundum GC”“Fujilundum GC”“Fujilundum WA”“Fujil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| average grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| incident angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com