Dosing System and Method

a technology of dosing system and dosing method, applied in the field of dosing system and method, can solve the problems of shortening the useful life of expensive equipment and inoperable equipment, and achieve the effect of minimizing exposure to unsavory aroma and/or tas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Embodiments of the invention relate to a system and method for introducing a chemical agent into a container.

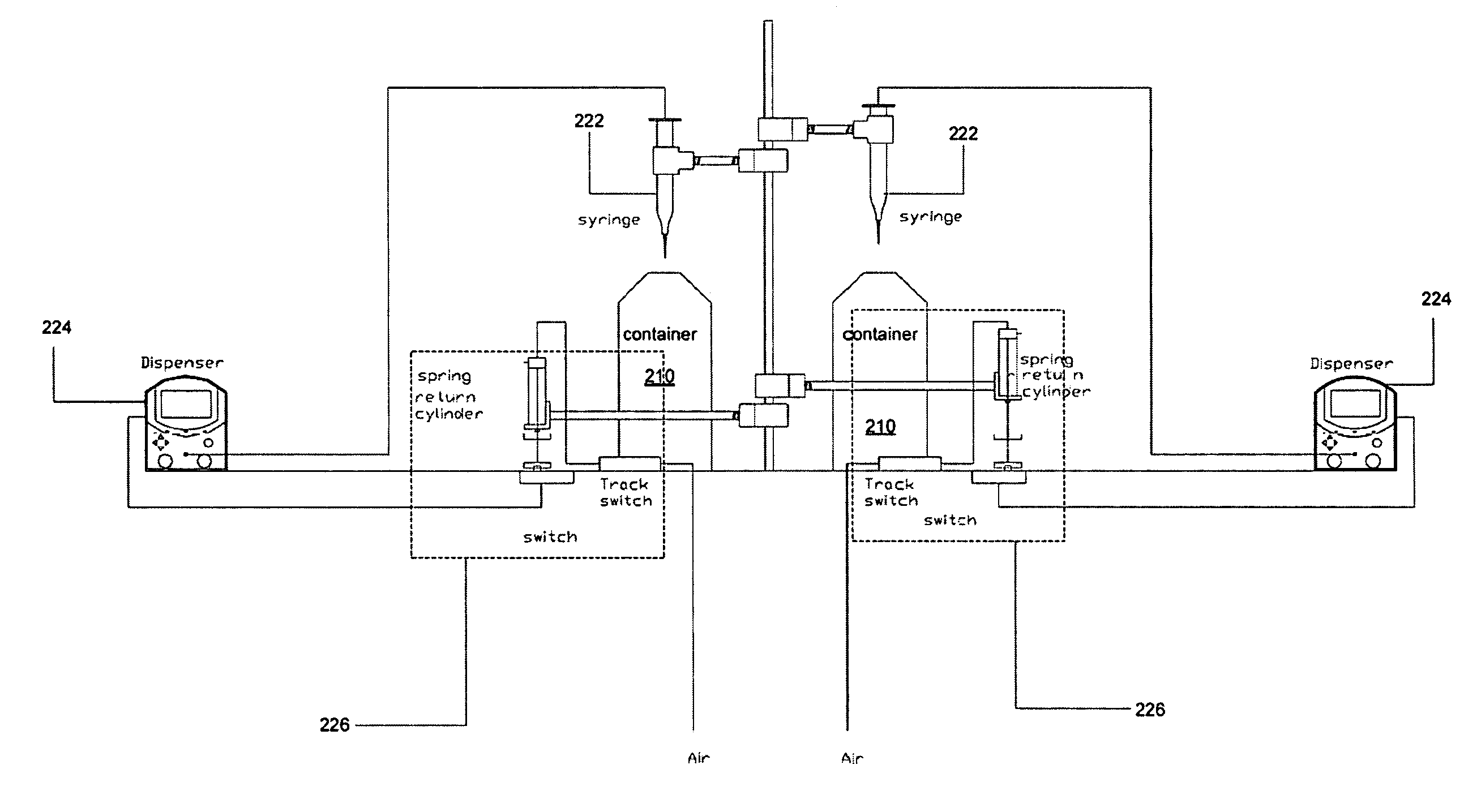

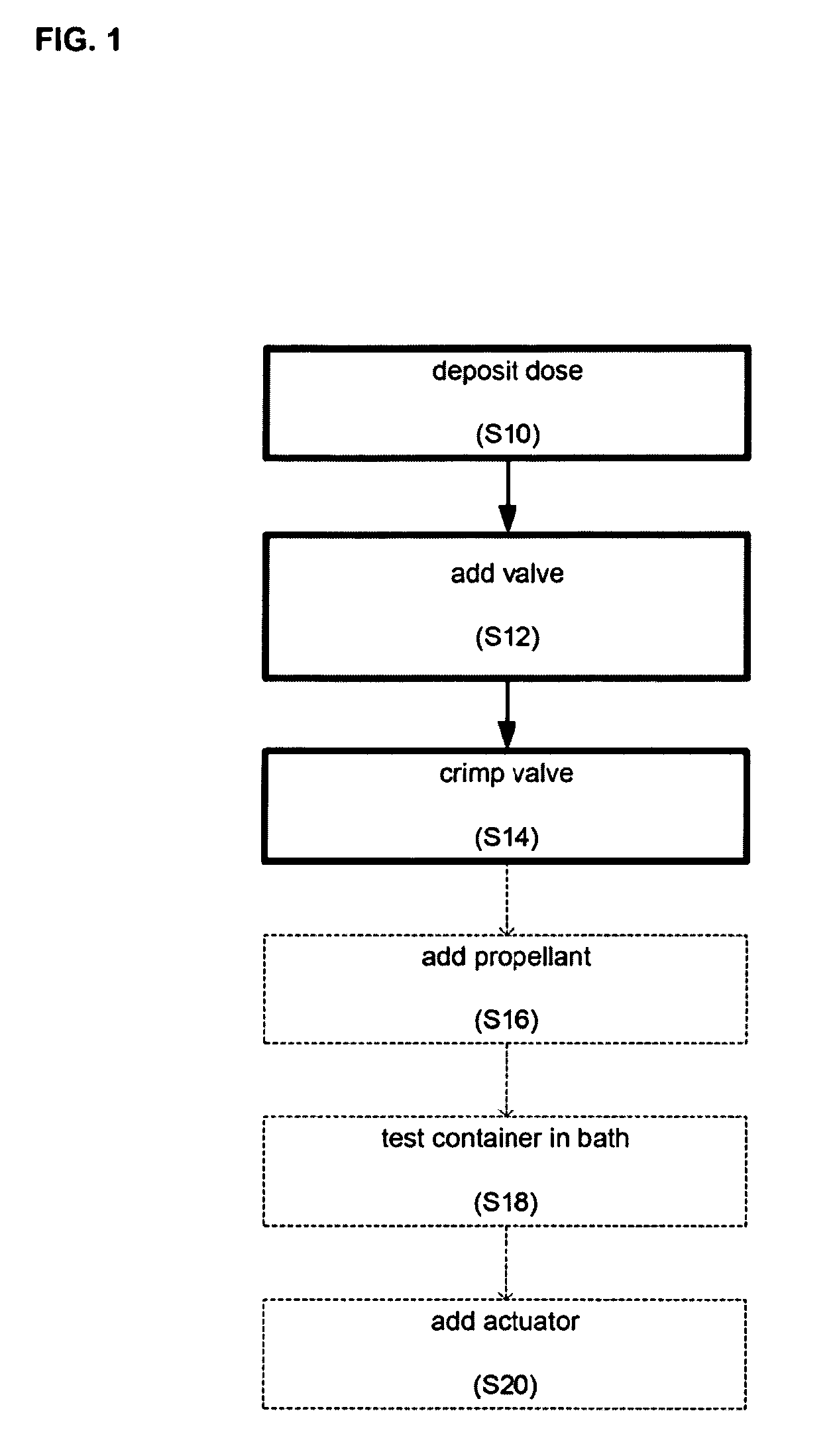

[0022]With reference to FIG. 1, in some embodiments, a method for adding a bittering agent to an aerosol container can include depositing a dose of bittering agent into a container (step S10), adding a valve to the container (step S12), and crimping the valve to the container (step S14).

[0023]With reference to FIG. 2, a system, shown in schematic form, in accordance with some embodiments can be used to perform the above-described method. A dose module 220 can be used to add a dose of a bittering agent into a container 210. Next, a valve module 230 can position a valve on the container 210. A crimp module 240 can crimp the valve to the container 210. A propellant module 250 can be used to add propellant to the container 210. The container 210 can be tested in a bath module 260. Finally, an actuator can be placed on the container 210 by the actuator module 270.

[0024]With ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com