Lubricant

a technology of perfluoropolyether oil and lubricant, which is applied in the field of lubricants, can solve the problems of perfluoropolyether oil not maintaining stable high-temperature characteristics, and achieve the effects of long-term stability, low friction characteristics, and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

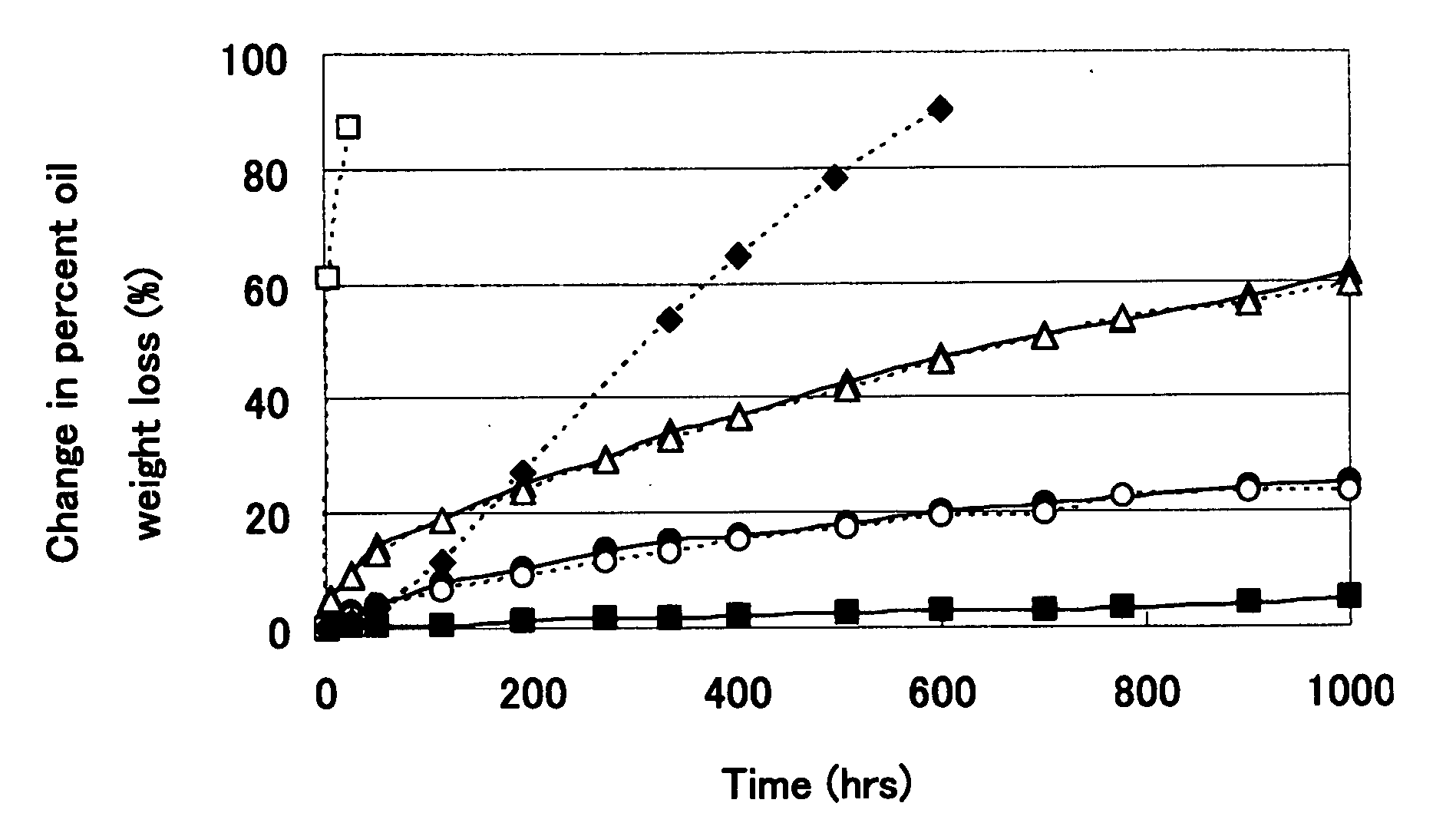

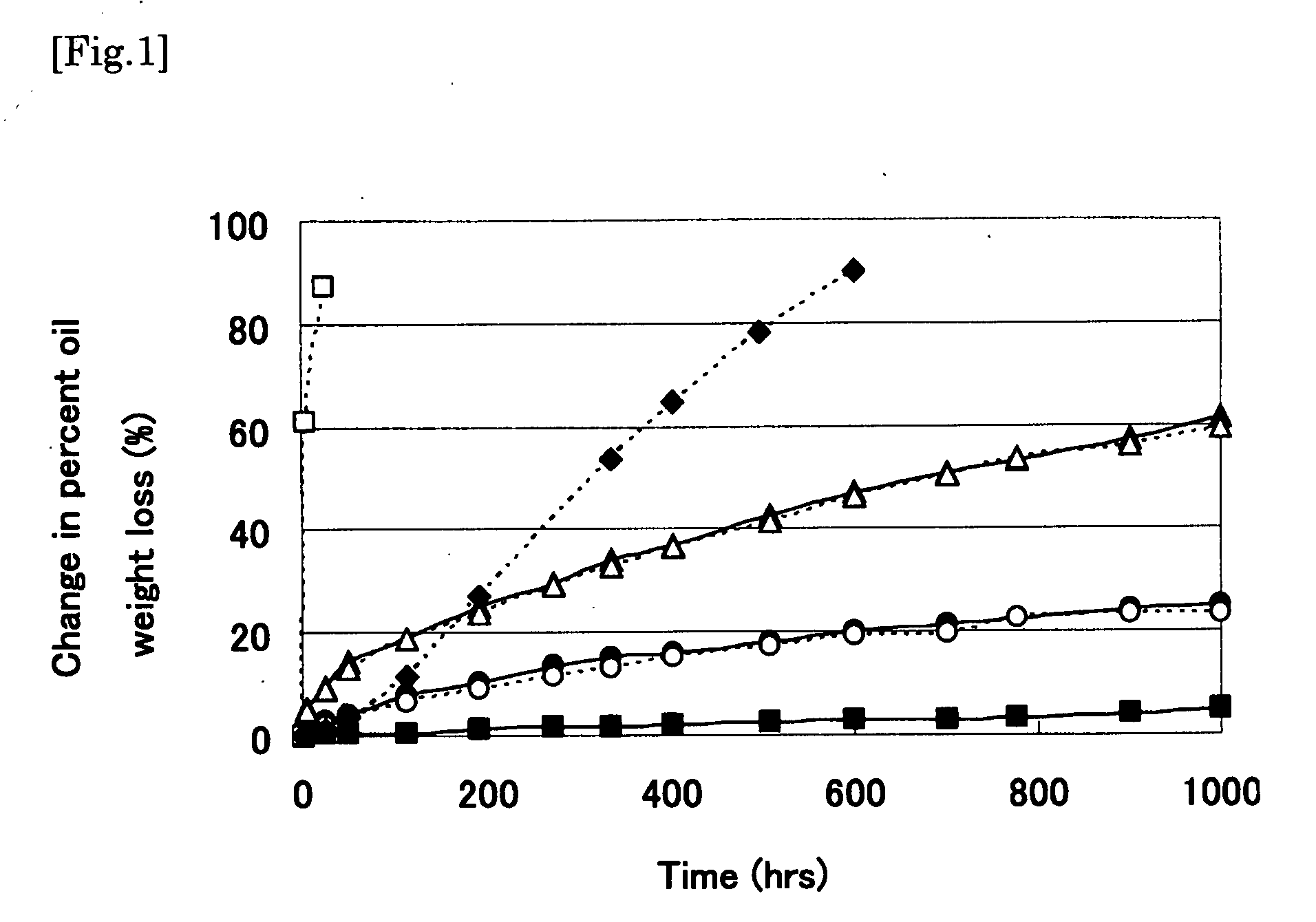

[0034]The following three kinds of perfluoropolyether base oils were admixed with 10% by weight of graphite powder (flake graphite powder CB-150, a product of Japan Graphite Co.; fixed carbon content: 98.0% or more, and average particle size: 40 μm), or molybdenum disulfide (LM13-SM powder, a product of Daito Lubricant Manufacturing Co.; average particle size: 0.4 μm) on the basis of the sample, and 0.6 g each of the samples was sampled into individual glass dishes, 36 mm in diameter, smeared onto the dish surfaces in a uniform thin film state, and left standing in a thermostat tank at 200° C. to determine changes in percent oil weight loss with time.

[0035]The results are shown graphically in FIG. 1, where[0036]: F(CF2CF2CF2O)mC2F5 (kinetic viscosity at 40° C.: 100 mm2 / sec.)[0037]◯: +graphite[0038]▴: RfO[CF(CF3)CF2O]p(CF2CF2O)qRf′ (kinetic viscosity at 140° C.: 180 mm2 / sec.)[0039]Δ: +graphite[0040]▪: RfO(CF2CF2O)m(CF2O)nRf′ (kinetic viscosity at 40° C.: 160 mm2 / sec.)[0041]: +graphi...

example 2

[0044]The following perfluoropolyether base oils (A) or (B) having various kinetic viscosities at 40° C. were admixed with 10% by weight of aluminum powder (a product of Wako Pure Chemical Co., purity: 99.5%, and particle sizes: 53-150 μm) on the basis of the sample, and 0.3 ml each of the samples was sampled into individual glass dishes, 37 mm in diameter, smeared onto the dish surfaces in a uniform thin film states and left standing in a thermostat tank at 250° C. to determine weights of entire glass dishes after 100 hours, thereby calculating percent oil weight losses.

[0045]Perfluoropolyether oil (A): F(CF2CF2CF2O)mC2F5 [0046]Kinetic viscosity at 40° C. (A-1) 65 mm2 / sec.[0047](A-2) 100 mm2 / sec.[0048](A-3) 200 mm2 / sec.[0049](A-4) 23 mm2 / sec.

[0050]Perfluoropolyether oil (B): RfO[CF(CF3)CF2O)pRf′[0051]Kinetic viscosity at 40° C. (B-1) 180 mm2 / sec.[0052](B-2) 400 mm2 / sec.[0053](B-3) 25 mm2 / sec.[0054](B-4) 1200 mm2 / sec.

[0055]Perfluoropolyether oil (C): RfO(CF2CF2O)m(CF2O)nRf′[0056]Kin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com