Air Flow Cooking Device

a technology of air flow and cooking device, which is applied in the field of applications, can solve the problems of not being able to establish, not being able to cook or heat up food in liquid cooking medium, and being likened to an oven, etc., and achieves the effect of facilitating the development of a large number of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

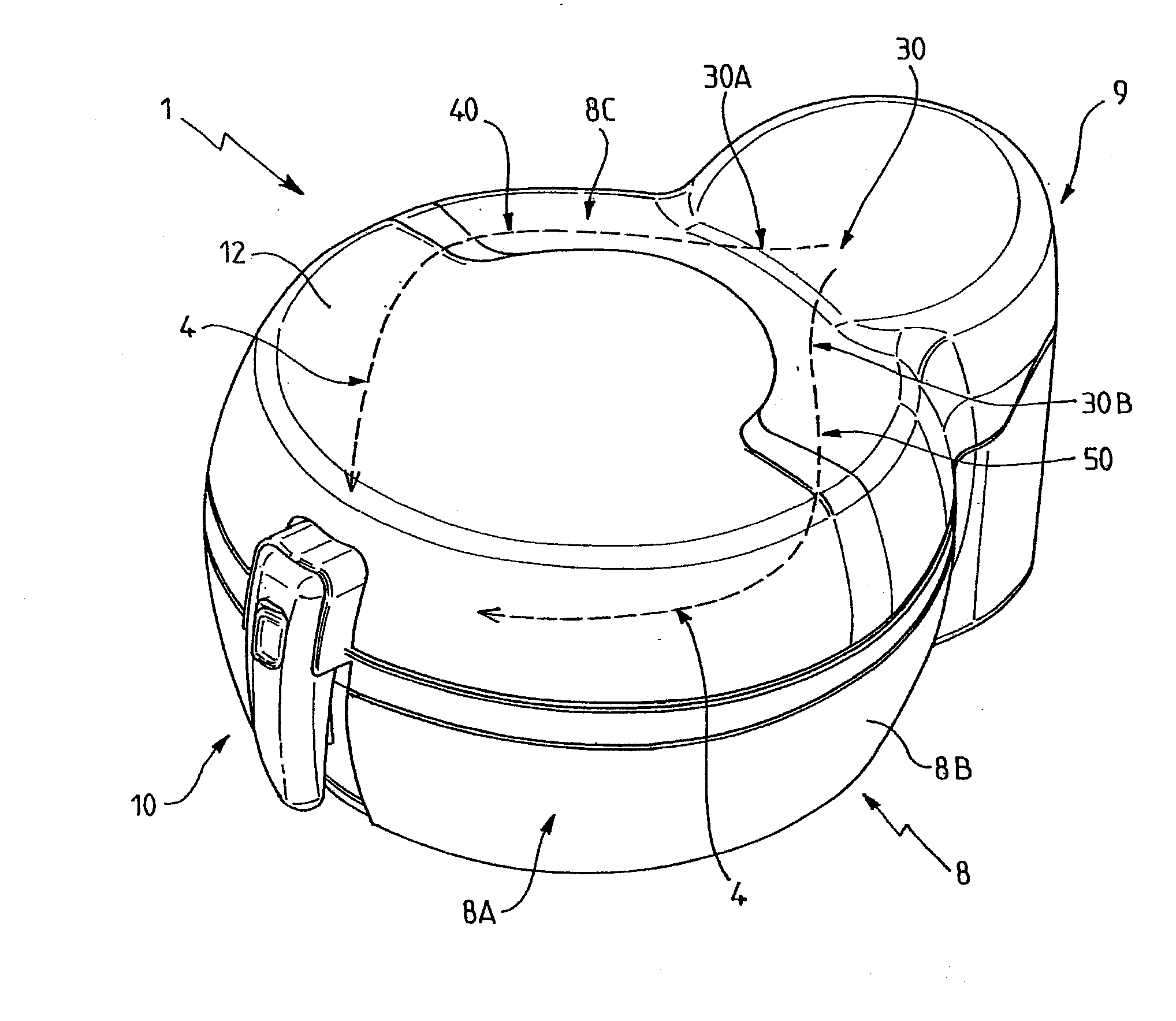

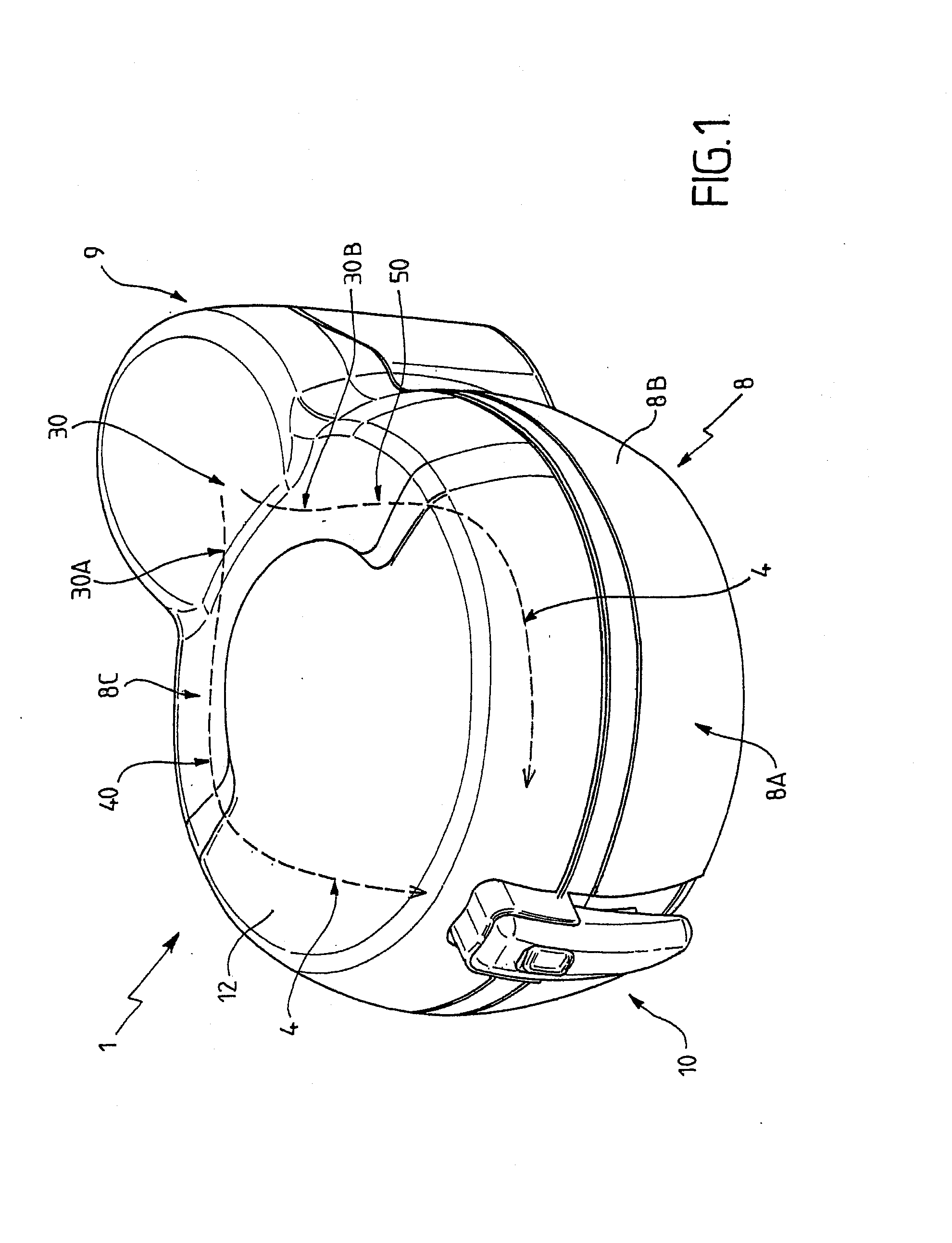

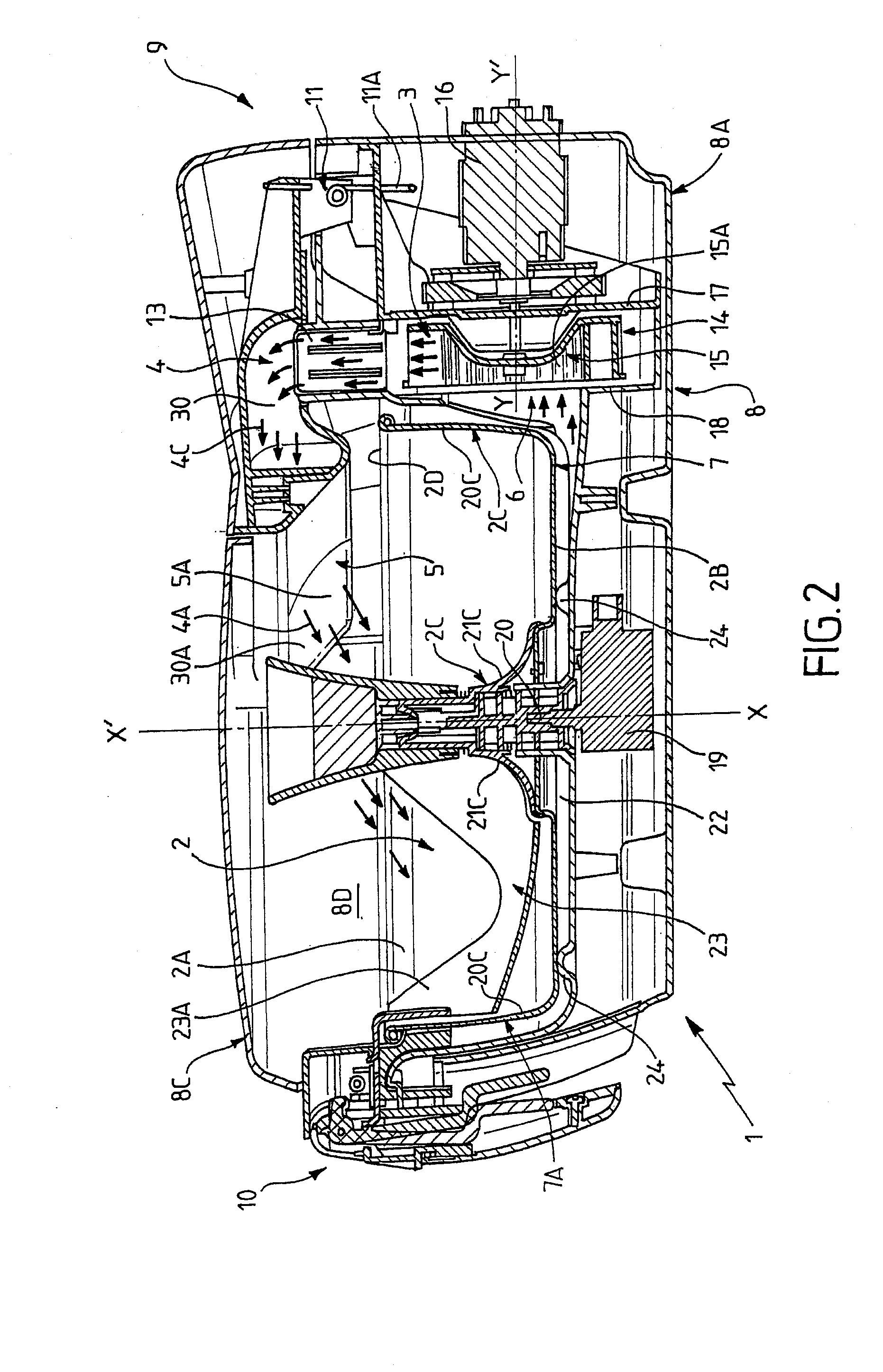

[0034]The invention relates to an appliance 1 for heating and / or cooking food for human consumption.

[0035]In accordance with the invention, the appliance 1 is a household appliance, i.e. it is specifically designed and dimensioned for household use, e.g. for a family. To this end, the appliance 1 can be manipulated by hand by its user, e.g. so as to be moved from a cupboard to a work surface. In other words, the appliance 1 is preferably portable.

[0036]The appliance 1 of the invention is preferably designed and dimensioned for cooking and / or heating particular types of food 100 (cf. FIG. 3), such as pieces of potato. Such food 100 can have been cut manually by the user, or they can have been purchased ready-prepared from a shop, in the pre-fried and / or frozen state, for example.

[0037]Depending on the type of food, the appliance 1 is thus used genuinely to cook the food (when the food is raw), or merely to heat the food (when the food is partially or fully pre-cooked).

[0038]As descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com