Installation Method for Non-Slip Sanitary Flooring

a technology of installation method and sanitary flooring, which is applied in the direction of resiliently mounted floors, flooring, building components, etc., can solve the problems of not adhesion well to certain underlying surfaces, requiring sophisticated priming or being limited to certain surface materials, and joints that change the otherwise (usually) level flooring may be unacceptabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention is a method of joining non-slip (non-skid) polymer sheet flooring materials suitable for sanitary use in a manner that improves the quality of the resulting seam while minimizing the problems raised by joints in general and welded joints in particular.

[0032] For background purposes, FIG. 1 illustrates a prior art joint broadly designated at 10. The joint is formed of respective portions 11 and 12 of polymer flooring, typically PVC as described earlier. In order to produce the joint 10, a router is used to cut enough material from each of the sheets 11 and 12 to define the respective oblique surfaces 13 and 14. A bead of welding material (usually, but not necessarily the same material as the flooring) indicated by the dotted circle 15 is applied between the surfaces 13 and 14 and melted to form the joint 16.

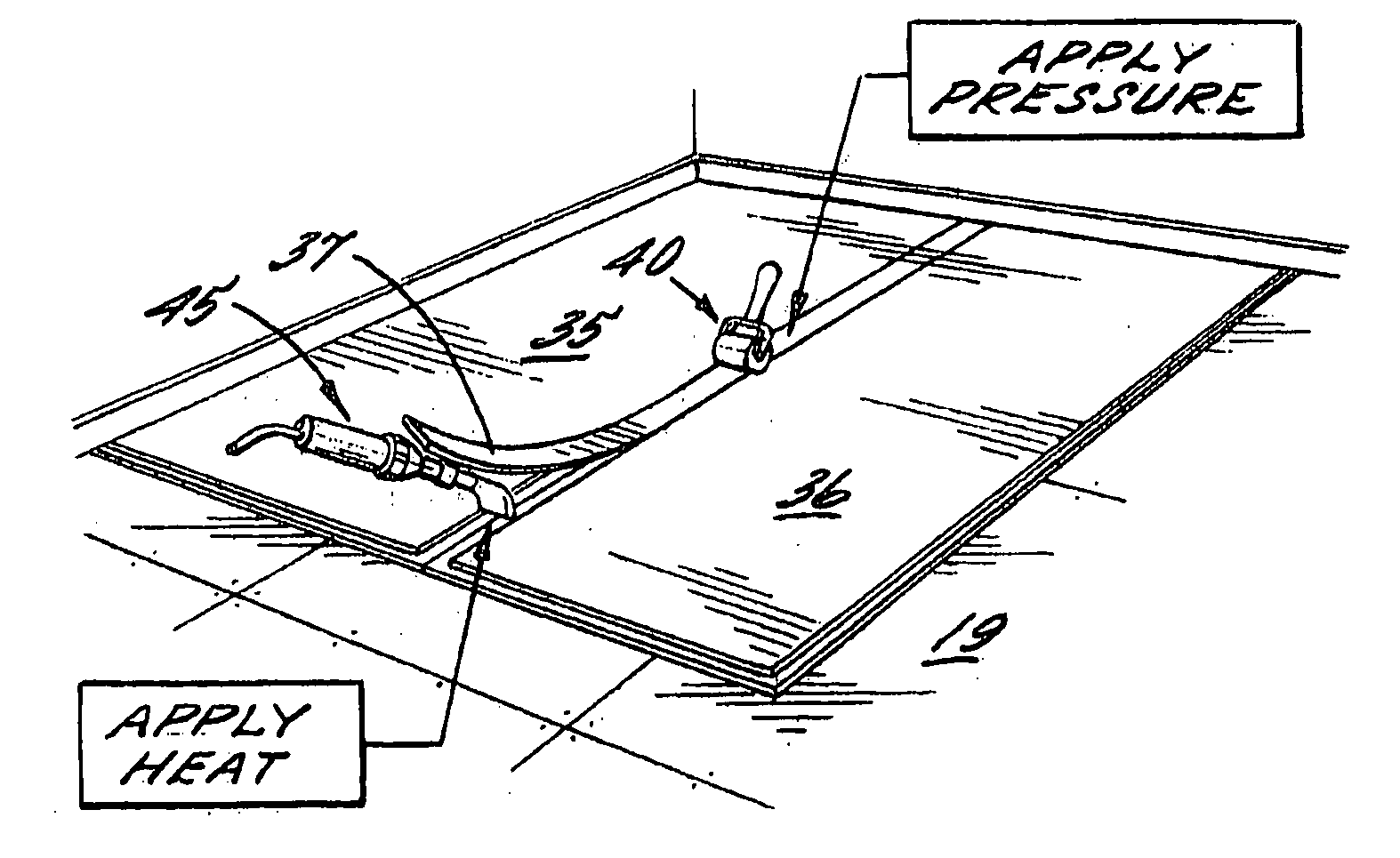

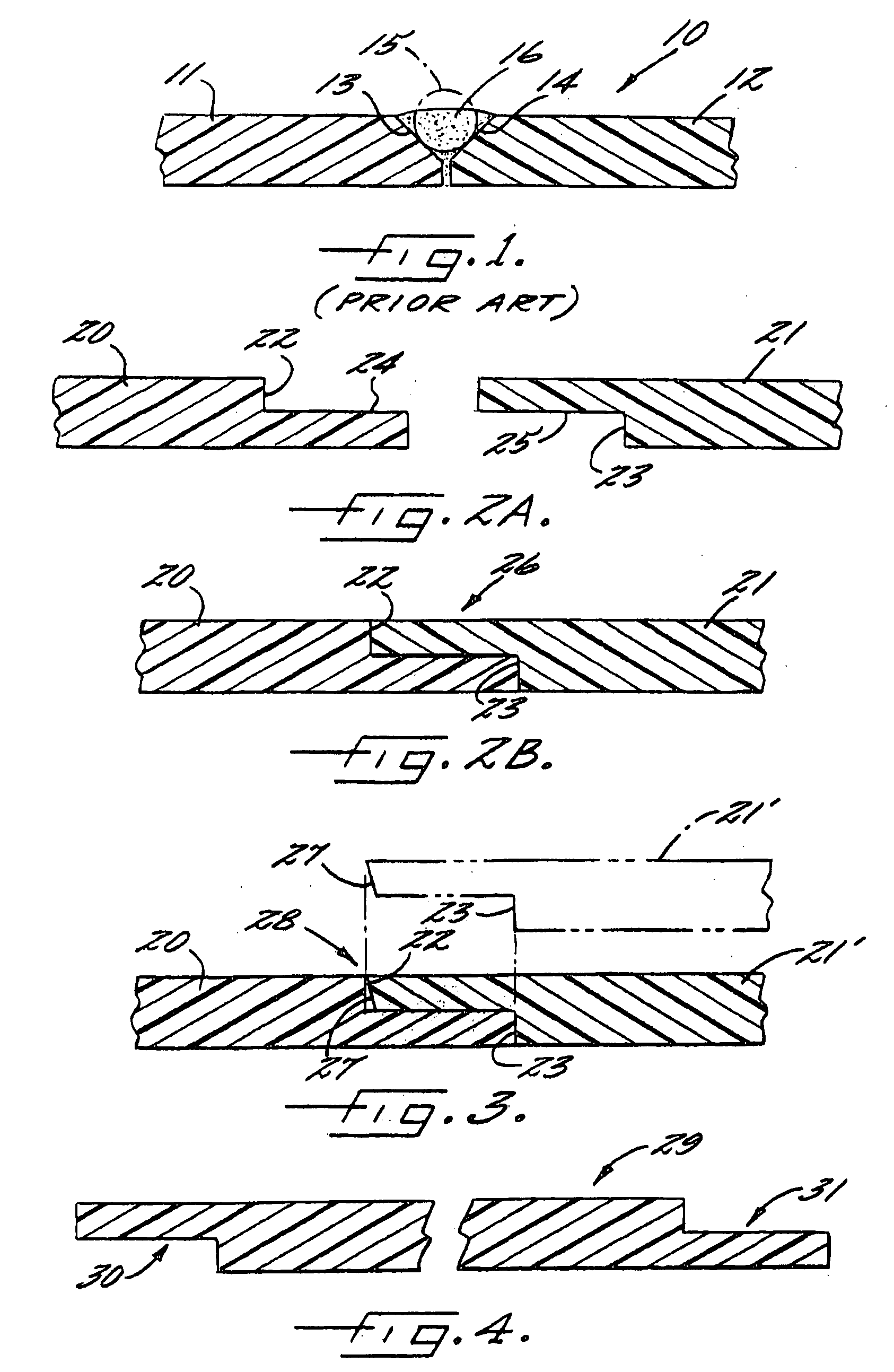

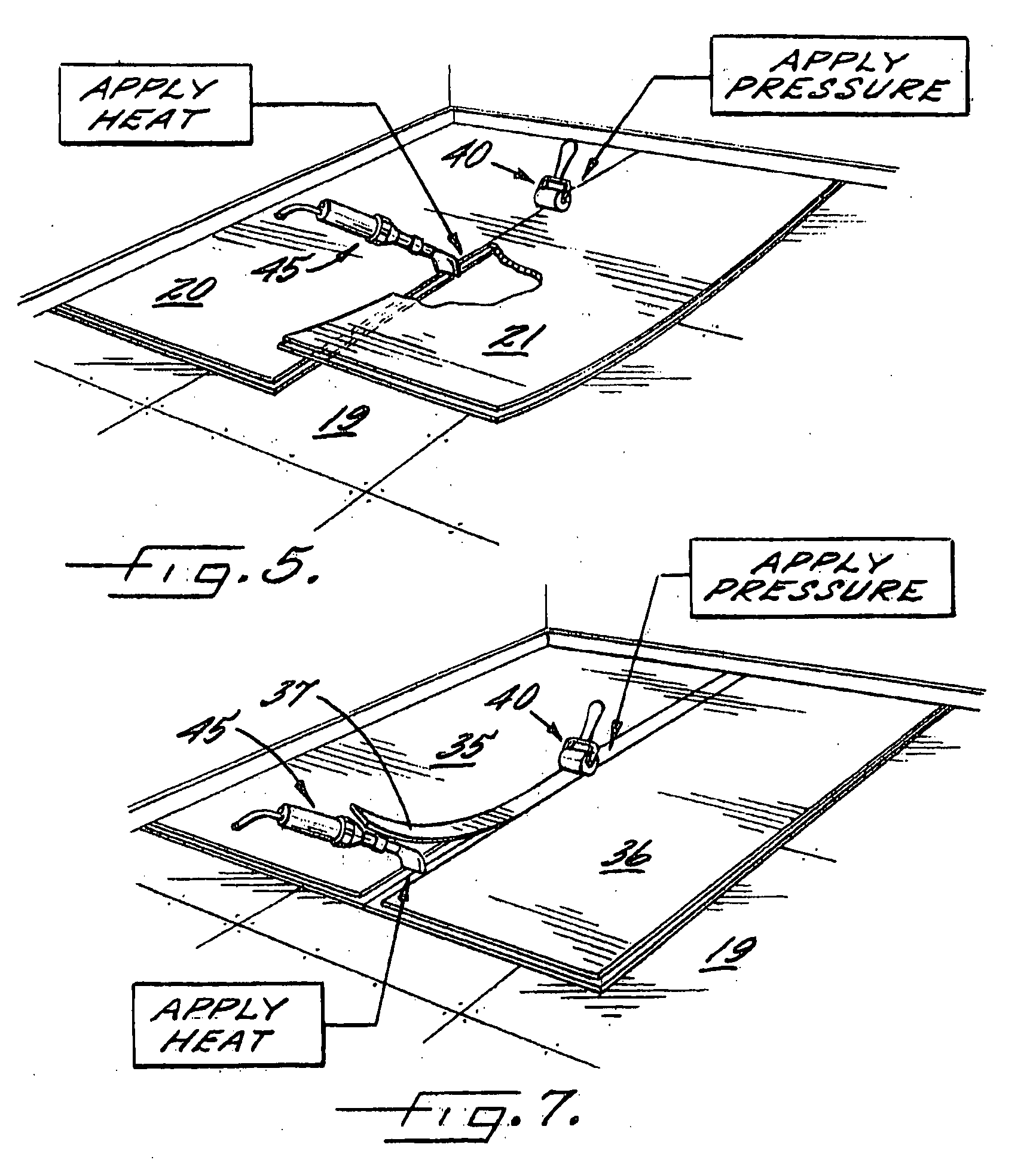

[0033]FIGS. 2A and 2B illustrate a step lap joint according to the present invention. The step lap joint is formed between respective first and second porti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com