Steel For Machine Structural Use With Excellent Strength, Ductility, And Toughness And Method For Producing The Same

a technology of ductility and toughness, which is applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of significant cost and threat to the production of steel, and achieve excellent strength, ductility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

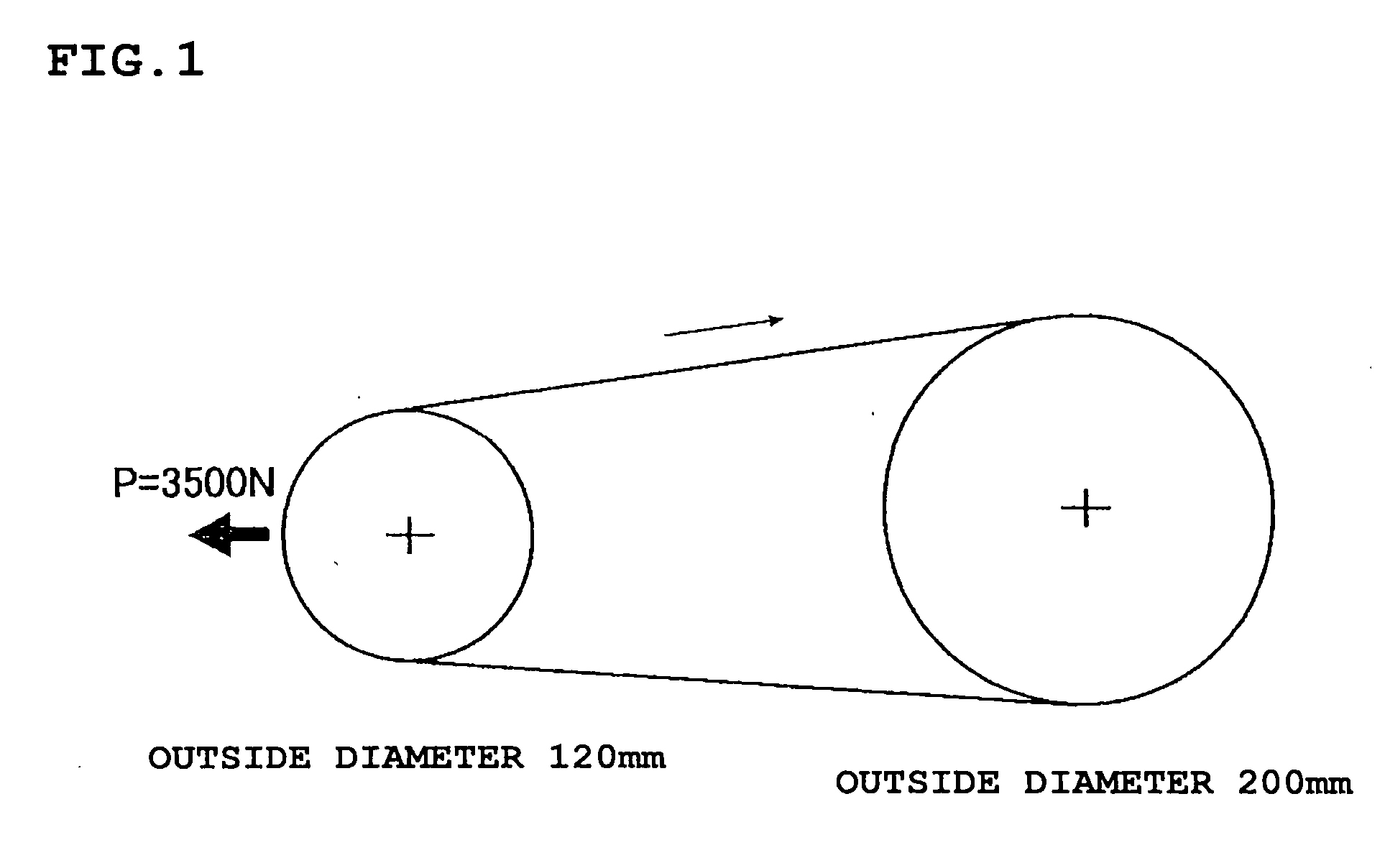

Image

Examples

example 1

[0082] Examples will now be described.

[0083] Steels shown in Table 1 were produced by vacuum melting. These steels were heated to 1,100° C. and were hot-rolled into sheets with a thickness of 3 mm. These sheets were pickled to remove surface scale and were cold-rolled. The rolling was repeated many times. After the sheets were rolled to a thickness of 0.8 mm, they were annealed to remove work strain and were further cold-rolled to a final thickness of 0.4 mm. These materials were subjected to heat treatment and evaluation described below.

[0084] The structures of the steels, which are to be subjected to high-frequency heating quenching, after the final heat treatment are expected to contain only a martensitic phase formed by transformation from the austenite temperature range, an untransformed ferrite phase that can result from insufficient heating, and undissolved inclusions and precipitates such as carbides. These phases can be discriminated by developing the structures by nital ...

example 2

[0094] The effect of structure was examined. All the test methods used were the same as those used in Example 1 except that the high-frequency heating was performed at varying temperatures to examine the effect of the volume percentage of martensite.

[0095] In comparative examples, for example, the amount of untransformed ferrite phase was increased by lowering the heating temperature. As a result, the volume percentage of martensite fell below 90%. The test results are shown in Table 2, which shows that the formation of less than 90% by volume of martensitic structure resulted in significantly decreased strength.

example 3

[0096] The effects of other components were examined. Steels shown in Table 3 were produced by vacuum melting. The test methods used were the same as those used in Example 1. The test results are shown in Table 3, which shows that excessive contents of chromium and titanium resulted in decreased strength and excessive contents of nickel, vanadium, and niobium resulted in a saturated effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com