Nitride Semiconductor Device And Production Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0065] Firstly, a first embodiment of the nitride semiconductor device according to the present invention will be described.

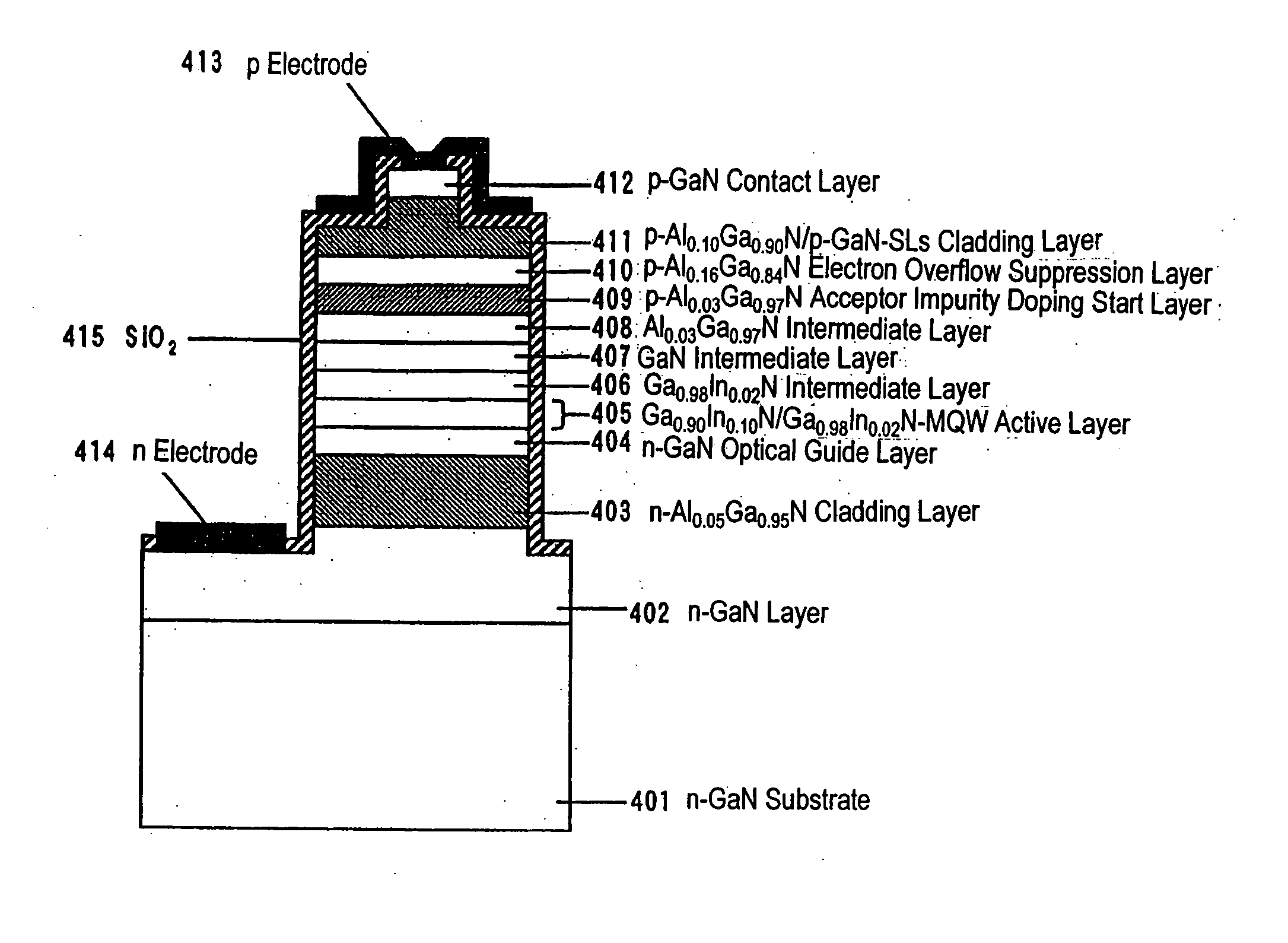

[0066]FIG. 4(a) shows a cross-sectional structure of the semiconductor laser of the present embodiment; and FIG. 4(b) is a schematic diagram of a conduction-band structure thereof. The semiconductor laser of the present embodiment includes an n-GaN substrate 401 and a semiconductor multilayer structure which is formed on the n-GaN substrate 401. Beginning from the substrate, this semiconductor multilayer structure includes: an n-GaN layer 402; an n-Al0.05Ga0.95N cladding layer 403; an n-GaN optical guide layer 404; a Ga0.90In0.10N / Ga0.98In0.02N-MQW active layer 405; a non-doped Ga0.98In0.02N intermediate layer 406; a non-doped GaN intermediate layer 407; a non-doped Al0.03Ga0.97N intermediate layer 408; a p-Al0.03Ga0.97N acceptor impurity doping start layer 409; a p-Al0.16Ga0.84N electron overflow suppression layer 410; a p-Al0.10Ga0.90N (2 nm thick) / p-GaN (2 ...

embodiment 2

[0117] In the present embodiment, after a semiconductor multilayer structure is formed similarly to Embodiment 1, this multilayer structure is processed into a stripe shape through a dry etching process. At this time, from the surface side, the p-GaN contact layer 412, the p-Al0.10Ga0.90N / p-GaN-SLs cladding layer 411, the p-Al0.16Ga0.84N electron overflow suppression layer 410, and the p-Al0.03Ga0.97N acceptor impurity doping start layer 409 are sequentially etched, almost until the non-doped Al0.03Ga0.97N intermediate layer 408 is exposed. The etching depth is an important parameter that determines the laser kink level and beam shape, and it is desirable to finely control the etching depth.

[0118] Monitor windows for optical evaluation, each being 50 μm per side, were provided in several places on the laser structure epitaxial wafer, and optical evaluations were performed in situ while conducting a dry etching process; thus, a dry etching was carried out.

[0119] In the present embo...

embodiment 3

[0122] Crystal growth for a laser structure was performed by using a construction similar to that of Embodiment 1, except for the structure of the p-type cladding layer. While Embodiment 1 employed the p-Al0.10Ga0.90N / p-GaN-SLs cladding layer 411, herein a p-Al0.08Ga0.92N / p-Al0.02Ga0.98N-SLs cladding layer 601 is used instead. FIG. 7(a) shows a structural diagram of this laser structure.

[0123] In the case where the p-Al0.10Ga0.90N / p-GaN-SLs cladding layer 411 is employed, supply / non-supply of TMA is periodically repeated to form AlGaN layers and GaN layers. If a uniform Mg doping is performed, the amount of Mg take-in will be reduced during the formation of the GaN layers, due to the memory effect. Conversely, when the AlGaN layers are formed, the amount of Mg take-in will rapidly increase near the interface. This will result in repetitive changes, each time stabilized at a constant value. Thus, as shown in FIG. 7(b), the Mg concentration is not stabilized within the cladding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com