Edge closure for roof systems

a roof system and edge closure technology, applied in the direction of roofs, walls, constructions, etc., can solve the problems of not providing venting capabilities, wood is susceptible to damage and deterioration, and the use of conventional wood blocking is not easy to achieve, and achieves less hardware, labor and materials, and increased rigidity and strength. , the effect of reducing the number of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

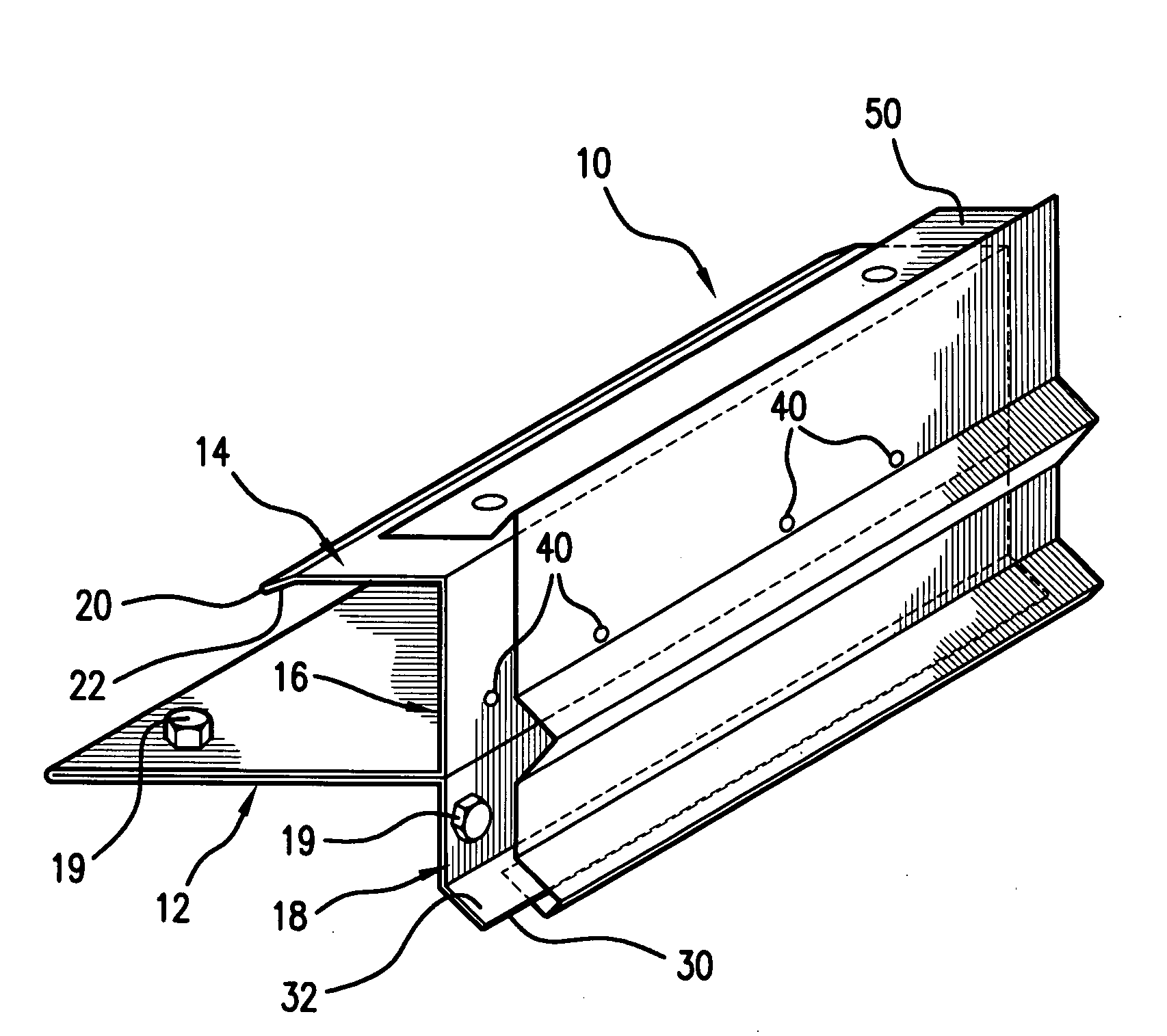

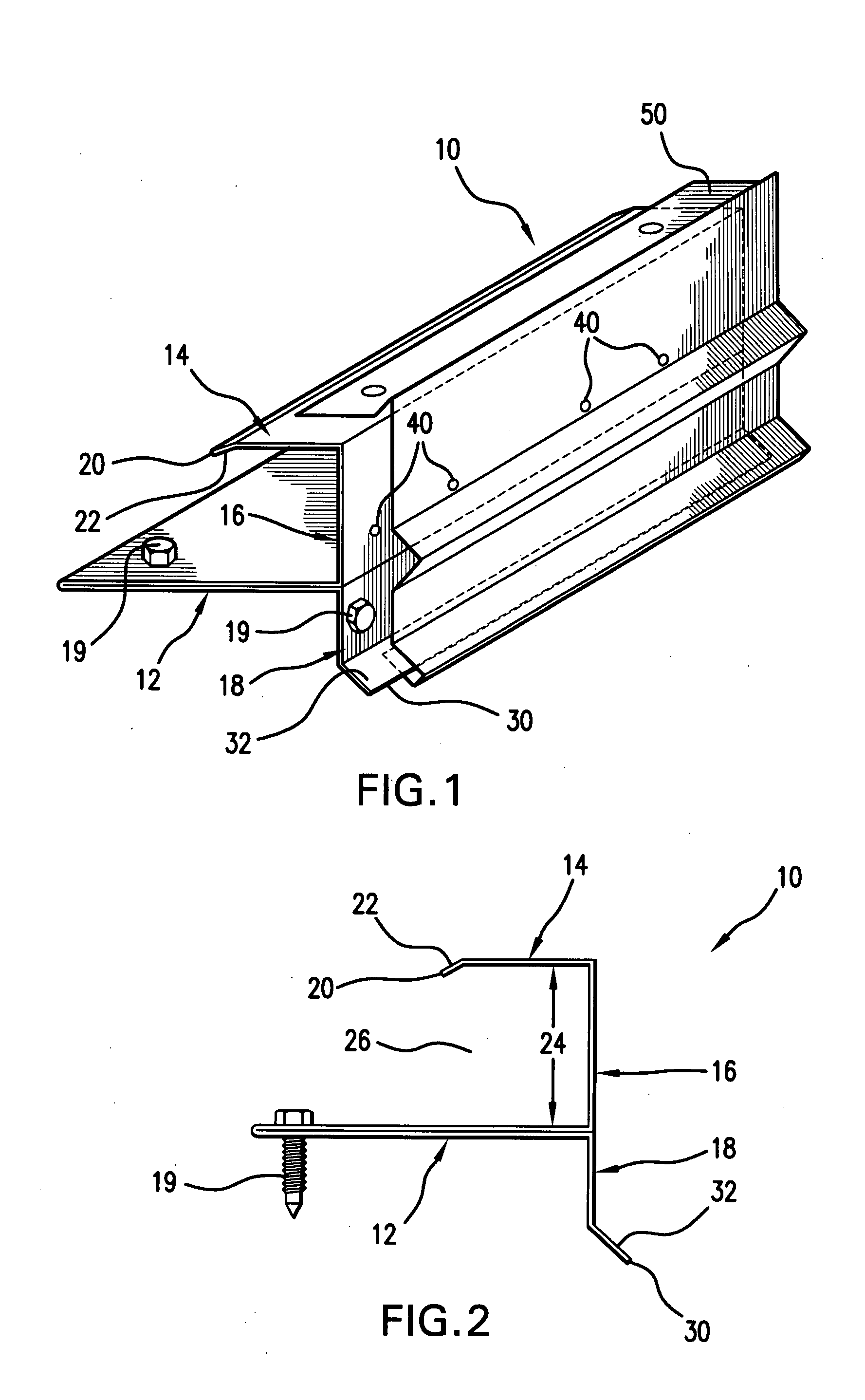

[0020]Referring to the several views of the drawings, the perimeter or edge closure is shown and is generally indicated as 10.

[0021]The edge closure 10 is preferably fabricated from a single sheet of material by roll forming, bending or extrusion. The edge closure 10 is formed of a non-corrosive, durable material, such as, but not limited to, steel, galvanized steel, aluminum or plastic.

[0022]The edge closure 10 is formed to include an anchoring flange 12, an upper flange 14 and an intermediate panel 16 spanning between the anchoring flange 12 and the upper flange 14. The edge closure 10 also includes a fascia portion 18 extending down from the anchoring flange, and in coplanar relation to the intermediate panel.

[0023]The anchoring flange extends outwardly from the intermediate panel a greater distance than the upper flange to provide an increased surface area for mounting to the roof structure with the use of approved fasteners 19, such as #14 roof fasteners with ¾ inch washers or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com