Water extraction from air and desalination

a technology of air and desalination, applied in the direction of defrosting, separation process, domestic cooling apparatus, etc., can solve the problems of air that is being compressed getting hot before it reaches the porous medium, reducing the relative humidity of air, and reducing the efficiency of water extraction. , to achieve the effect of reducing the energy consumption of water extraction, and reducing the cost of water extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Adiabatic Water Producer

[0033]We can use isothermal compression or adiabatic compression to provide the increased pressure of the air. We first consider the adiabatic method. In this case, we would prefer to minimize the heat exchange between the air and the cylinder walls and the piston, since this represents an energy loss. The interior volume of the cylinder should be relatively large, and the cylinder walls and the piston face should be lined with Teflon or other insulating material. Having the machine run fast also reduces heat loss.

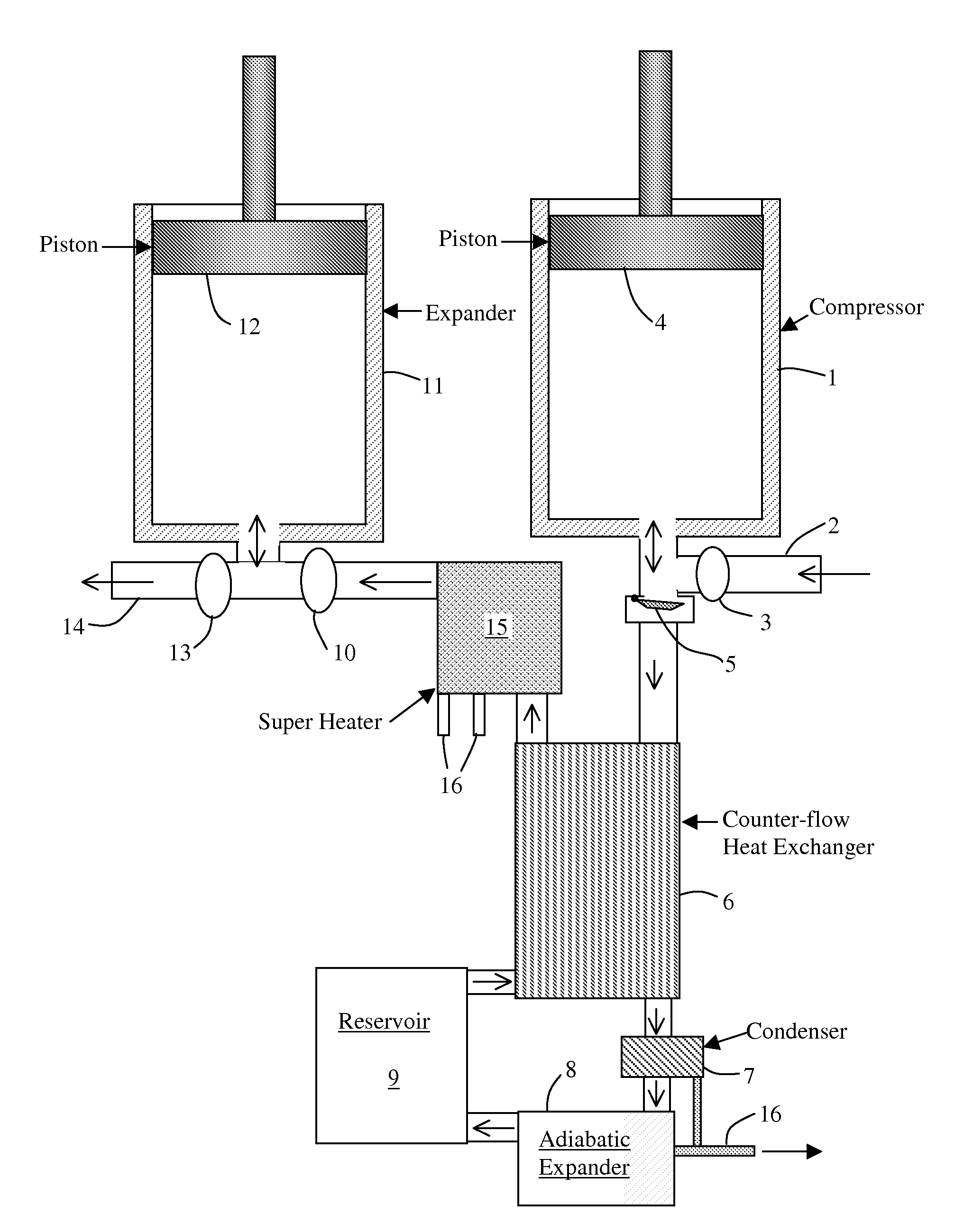

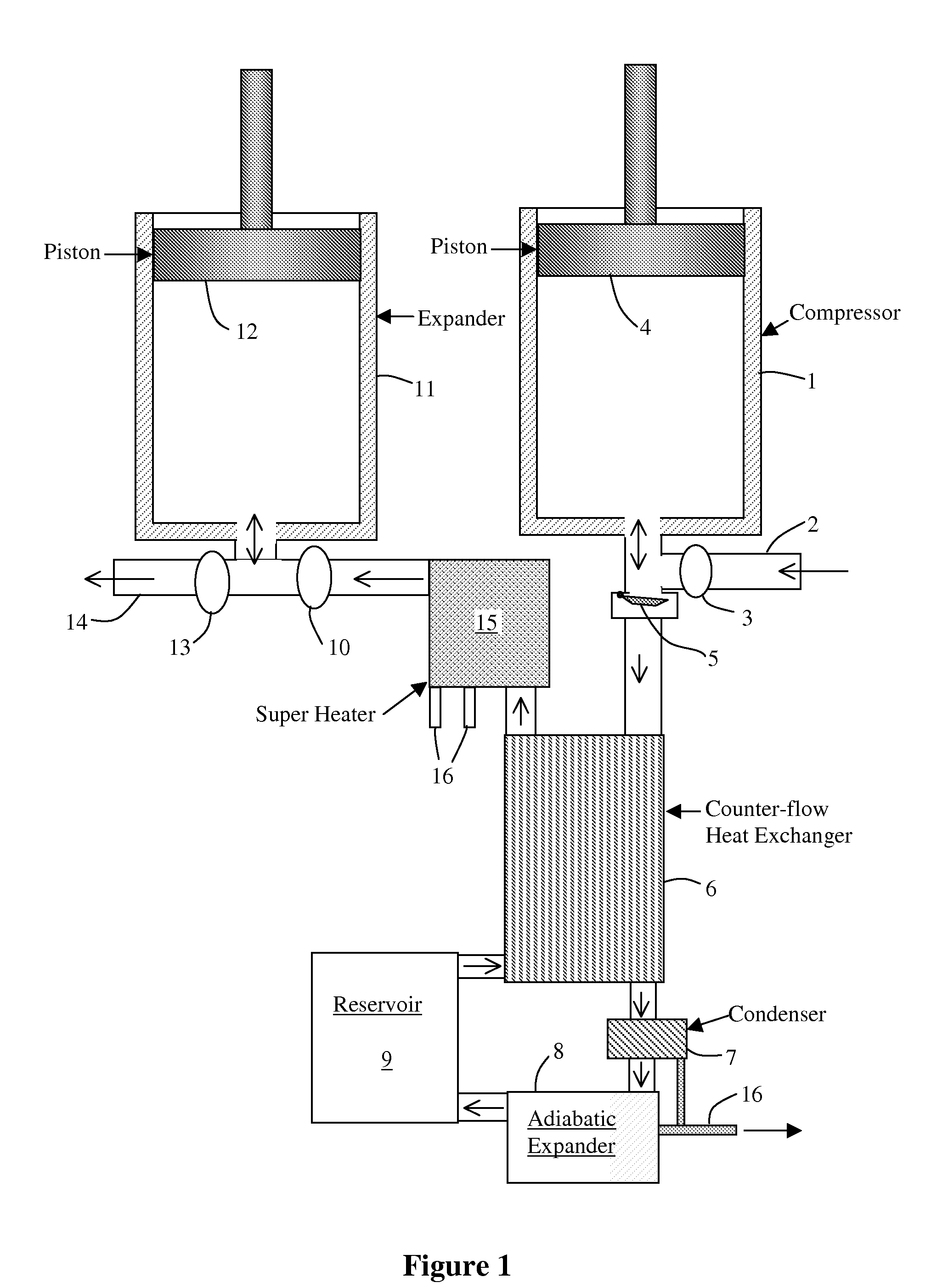

[0034]FIG. 1 shows one embodiment of the adiabatic Water Producer. For the first stroke, the piston 4 in the compressor 1 moves upward and draws in ambient air through intake 2 with valve 3 open. Then valve 3 closes, and the piston 4 moves downward and compresses and heats the air. When the air pressure in the compressor 1 becomes greater than the pressure in the counter-flow heat exchanger 6, the check valve 5 opens and compressed air flows into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com