Intraocular lens implant

a technology of intraocular lens and implant, which is applied in the field of intraocular lens implants, can solve the problems of inability to accommodate, and achieve the effects of high refractive index, high elasticity, and similar siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

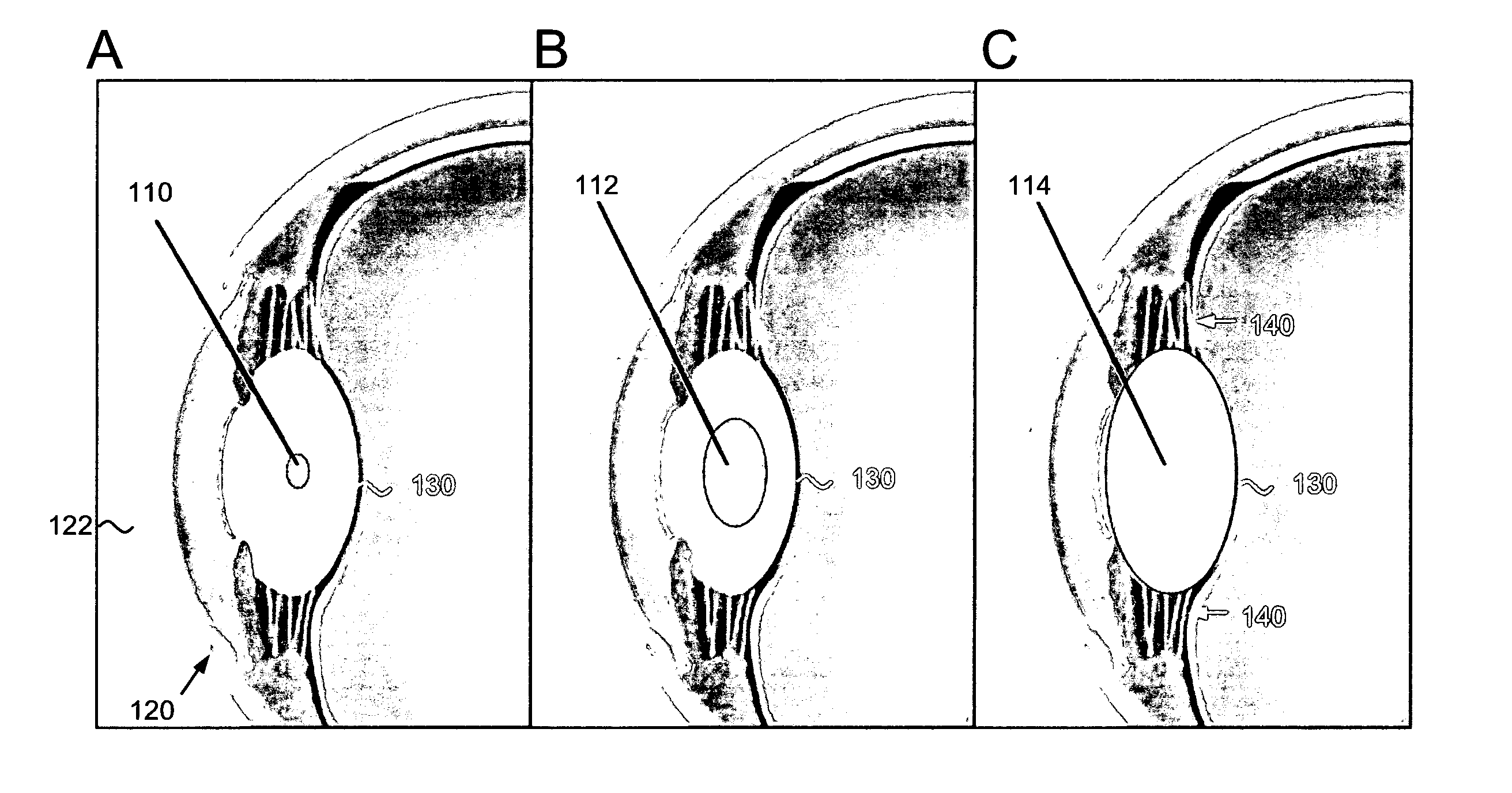

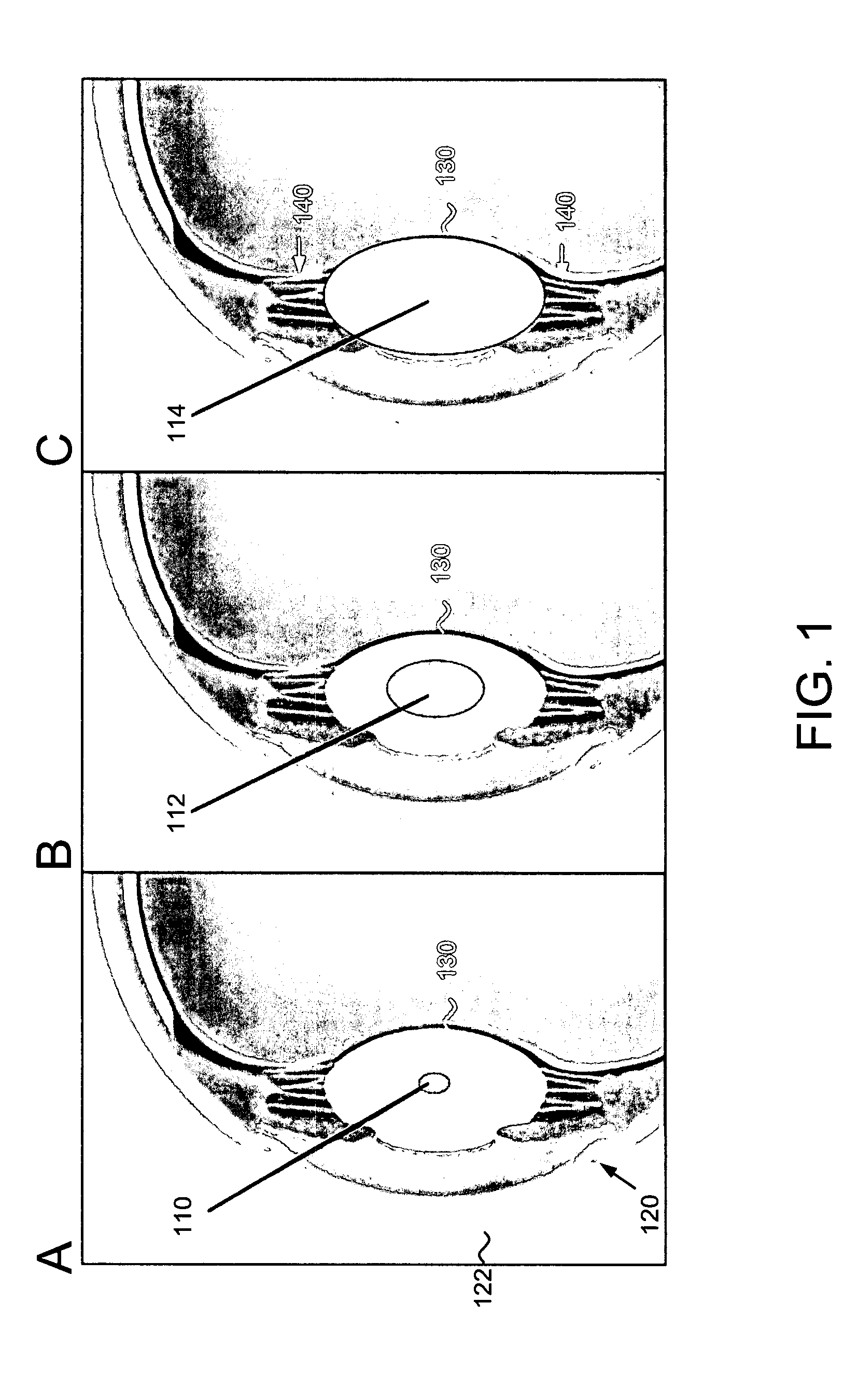

[0017] The present invention provides a hydrogel-based IOL capable of covalently binding to a lens capsule upon implantation into an eye. The hydrogel may be composed of any polymer capable of rapid swelling upon hydration. A schematic of swelling of an IOL on implantation into a lens capsule is shown in FIG. 1. FIG. 1A shows a dehydrated IOL 110 that has been implanted through incision 120 in cornea 122 into lens capsule 130. In FIG. 1B, dehydrated IOL becomes partially hydrated 112 on exposure to the aqueous environment of the lens capsule 130. In FIG. 1C, the IOL is fully swollen 114 within lens capsule 130. Fully swollen IOL 114 can then be controlled by zonules 140 to accommodate the curvature of the lens to different distances.

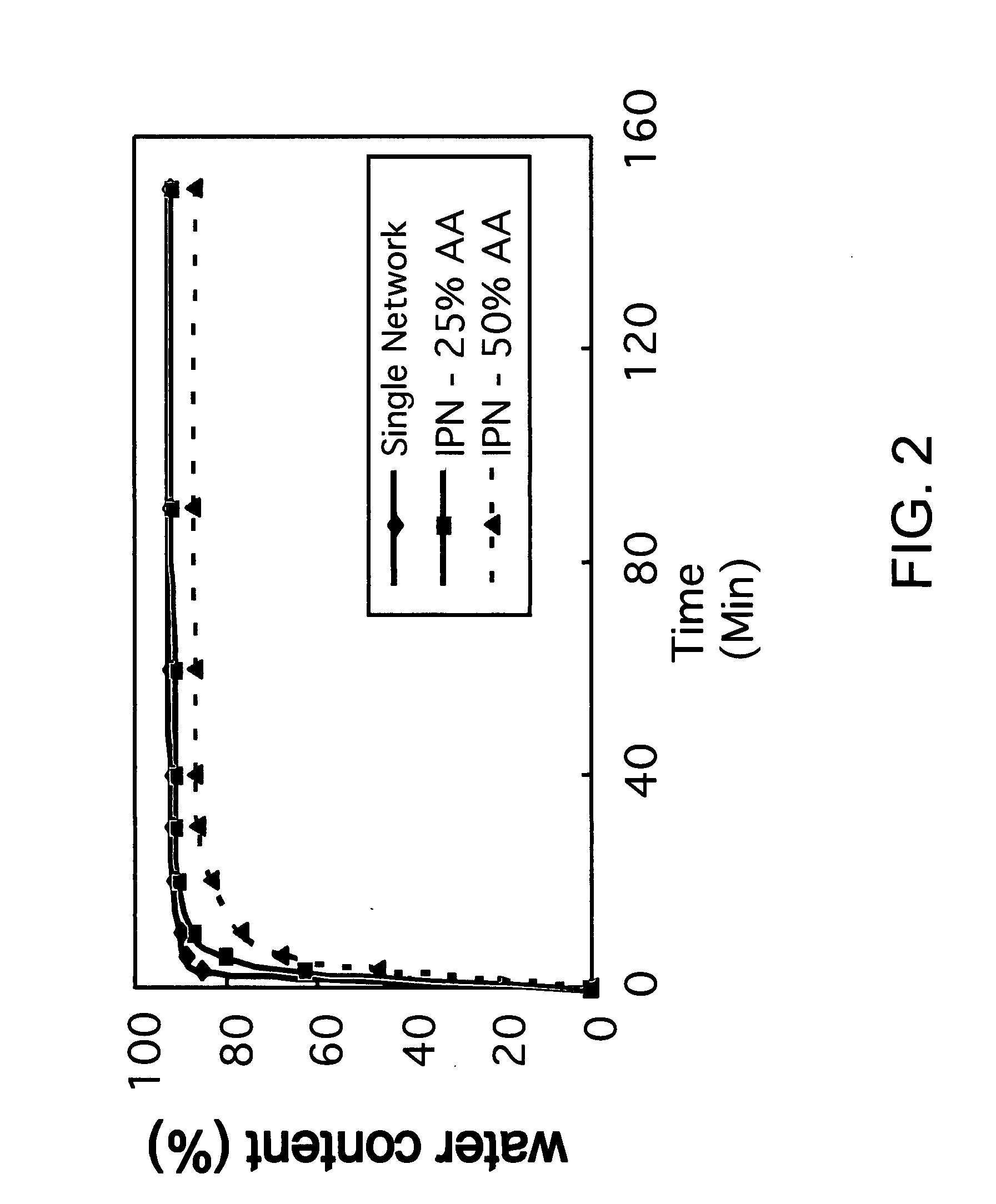

[0018] Preferably, the hydrogel can swell from a dehydrated state to a rehydrated state within about 2 hours. Also preferably, the volume and weight ratios of dehydrated versus rehydrated hydrogel are between about 10:90 (dry:swollen) and about 40:60 (d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com