Apparatus and method for combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

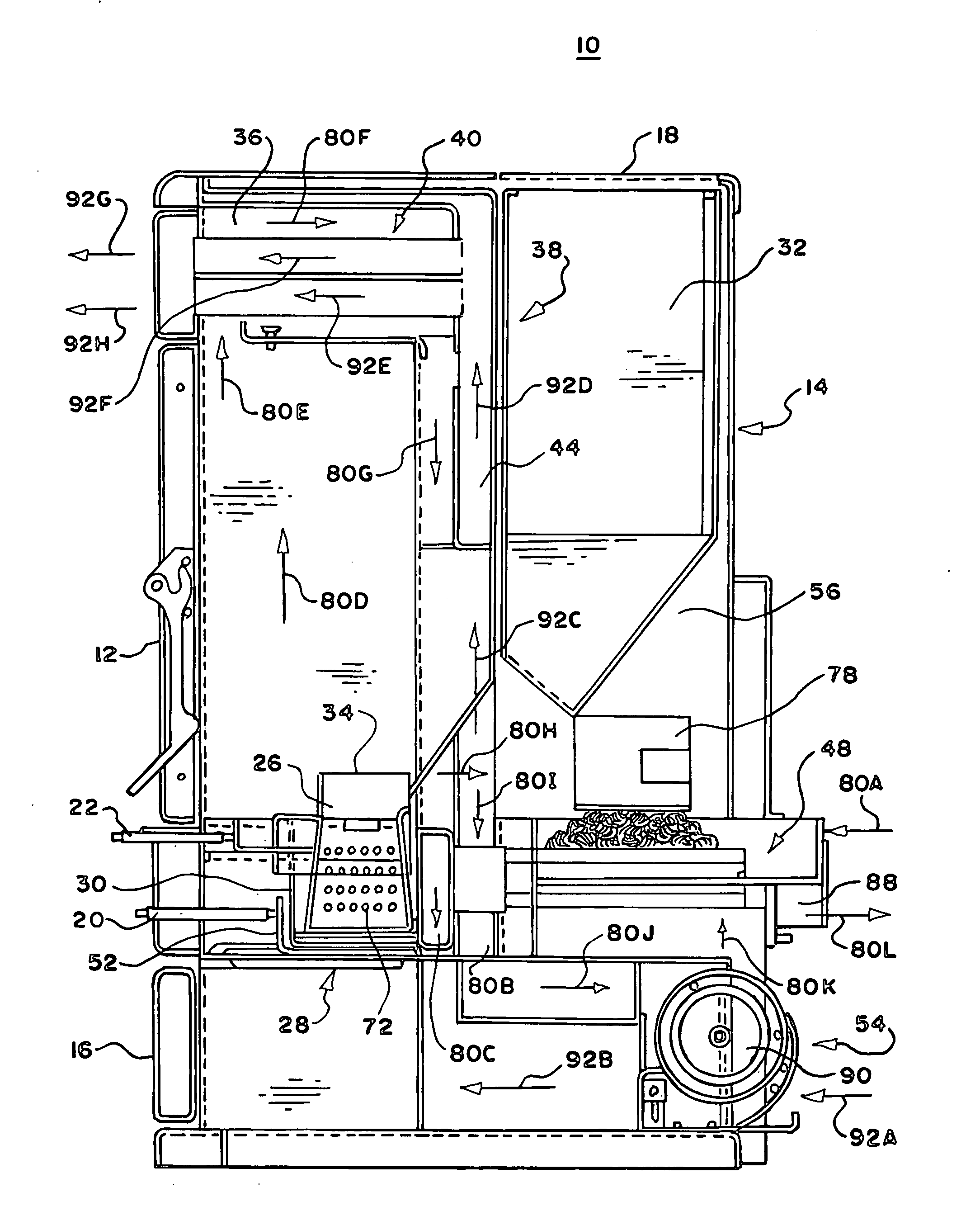

[0052] In FIG. 1, there is shown a perspective view of a burner 10, which may be for example a stove or furnace, having an enclosure 14, with an access door 12, an ash pan 16, a rod 20, a rod 22, a heat exchanger tube scraper rod 24 and a fuel hopper lid 18. The access door 12 has a transparent window through which a firebox can be seen having within it a burnpot chamber, a burnpot, a feeder system, an exhaust system, a heat exchanger system and a combustible air intake system, none of which are shown in FIG. 1. The fuel hopper in the preferred embodiment includes the hinged fuel hopper lid 18 in the top of the enclosure 14 exposing an opening through which fuel, such as for example wood pellets or corn can be poured. To permit operation of the stove or furnace 10 from outside the enclosure 14, the rod 20 is connected to an openable bottom of a burnpot (not shown in FIG. 1), the rod 22 is connected to a combustion retention slide (not shown in FIG. 1), and the heat exchanger tube sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com