Cooling block forming electrode

a technology of cooling block and electrode, which is applied in the field of cooling block forming electrode, can solve the problems of corroding the inner peripheral surface of the channel b>14/b>, cracking of the alumite coating film, and blockage of the cooling liquid in the channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

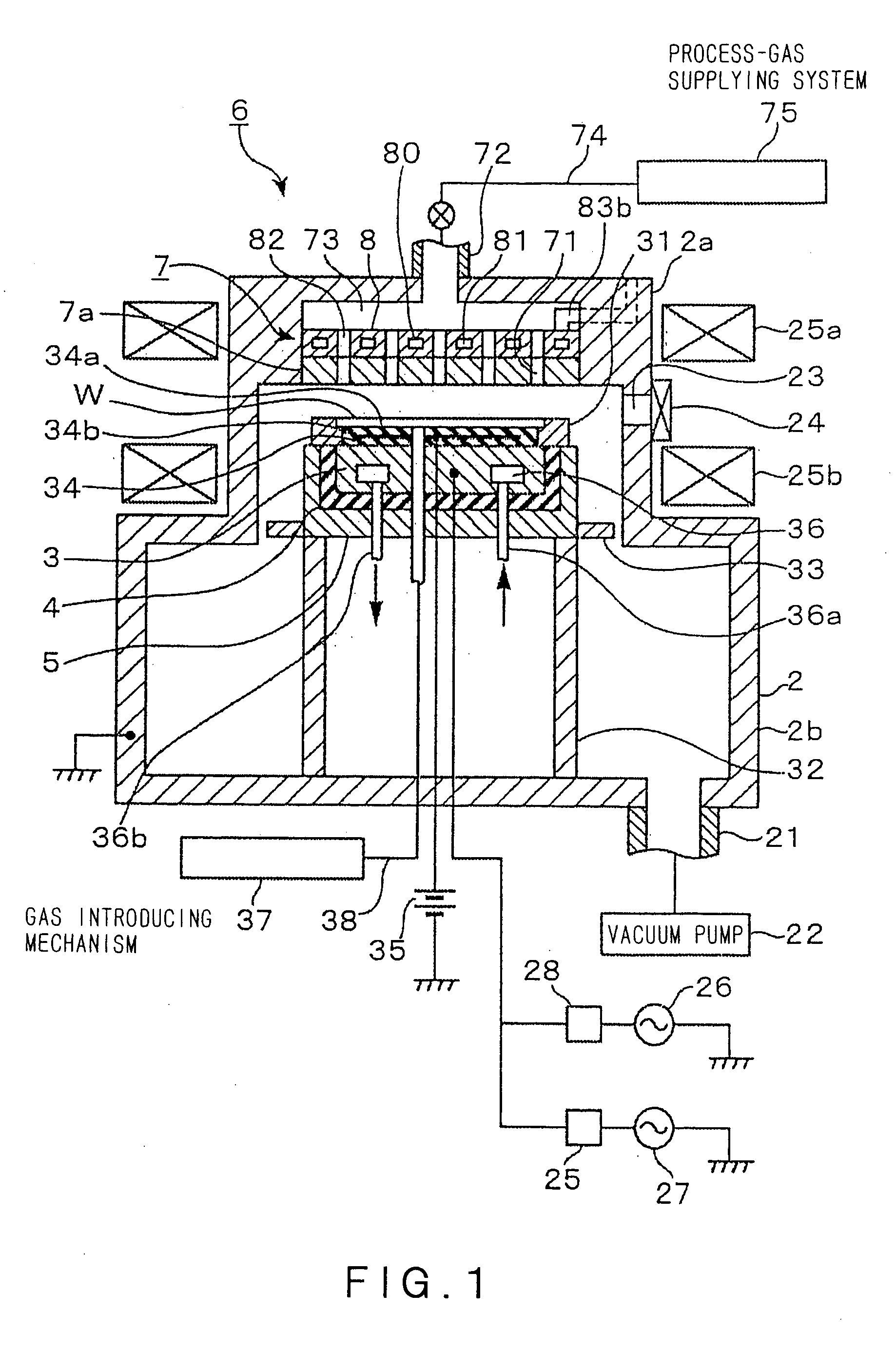

[0037]FIG. 1 is a schematic sectional view of an RIE (Reaction Ion Etching) plasma etching apparatus including a cooling block in a first embodiment of the present invention. As shown in FIG. 1, the plasma etching apparatus in this embodiment includes a process vessel 2 (vacuum chamber) made of, e.g., aluminum. The process vessel 2, which has an upper cylindrical part 2a of a smaller diameter and a lower cylindrical part 2b of a larger diameter, can be hermetically sealed.

[0038] In the process vessel 2, there is disposed a support table 3, which supports horizontally a semiconductor wafer W (hereafter referred to as “wafer”) as a substrate to be processed and also serves as a lower electrode. The support table 3 is made of, e.g., aluminum, and is supported by a conductive support base 5 via an insulating plate 4. A focus ring 31 made of, e.g., silicon (Si) is disposed on an upper periphery of the supporting table 3. A lower part of the support base 5 is covered with a cover 32. A b...

second embodiment

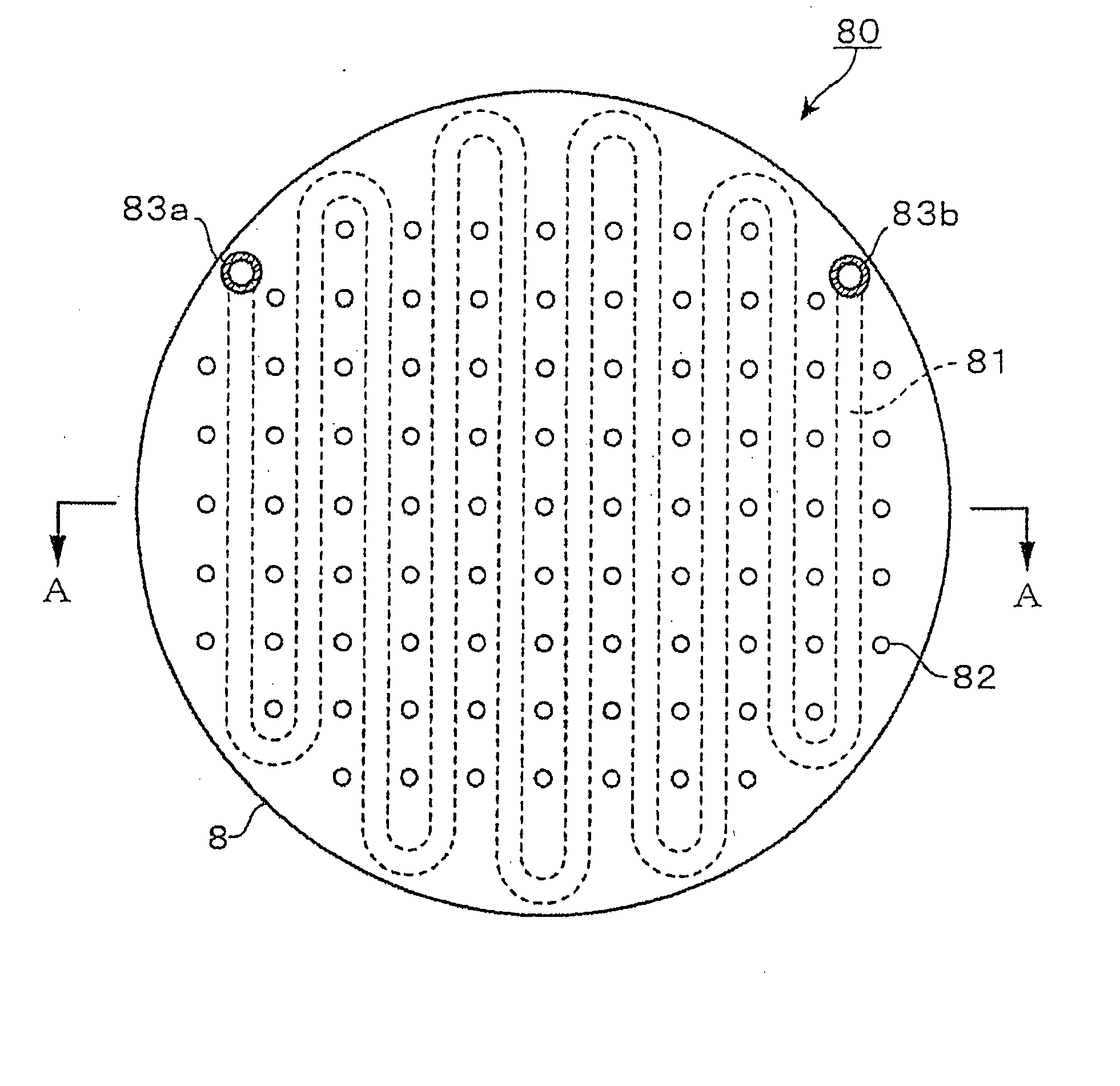

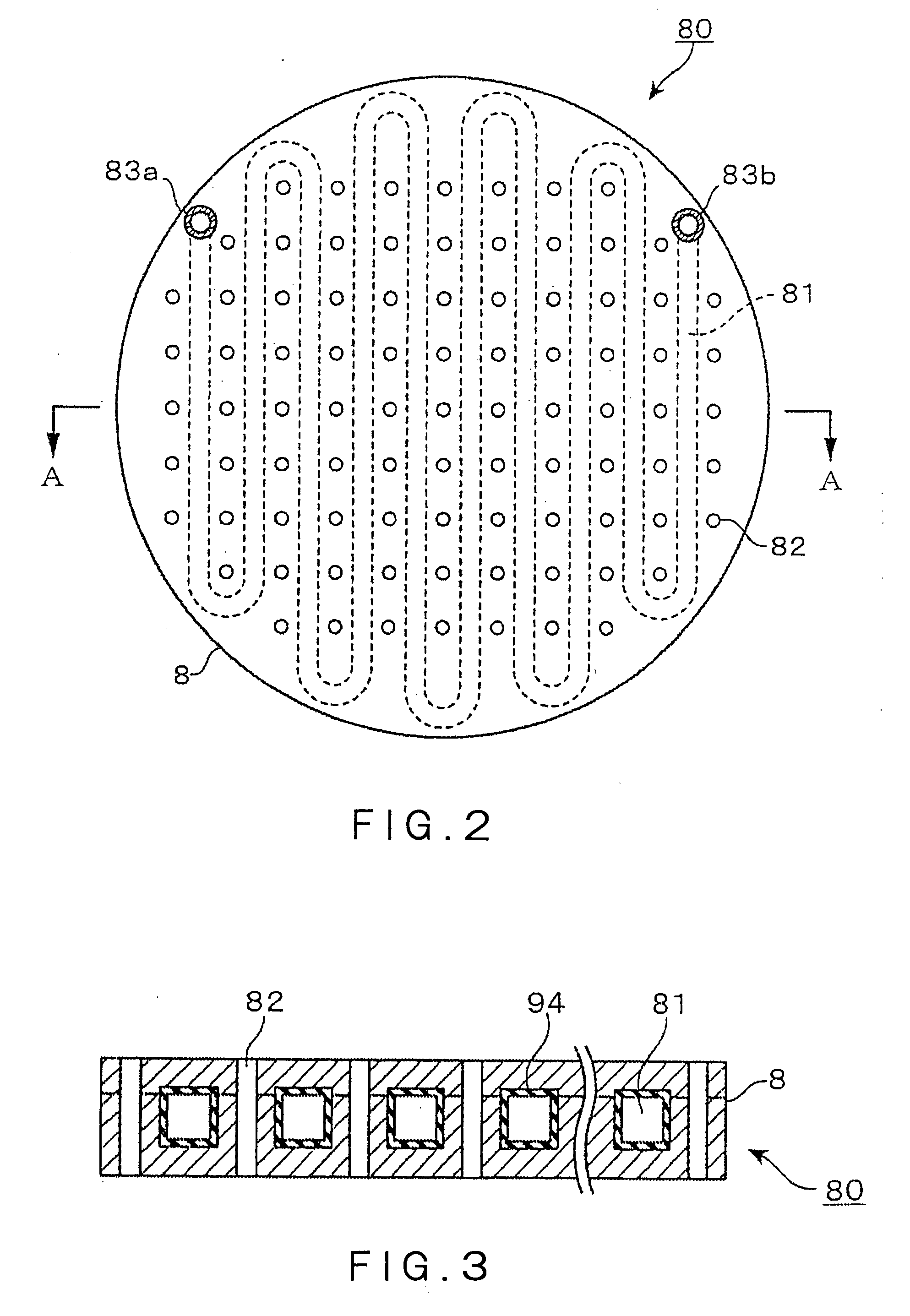

[0065] In a cooling block in a second embodiment of the present invention, an inner surface of a channel 81 formed in a base material 8 is entirely covered with stainless steel (SUS).

[0066] A manufacturing method of such cooling block 90 is concretely described with reference to FIGS. 6A to 7D.

[0067] At first, as shown in FIGS. 6A and 6B, a lower plate 94a made of SUS is processed to have, e.g., parallel grooves as recesses 80a for forming a channel. Holes 95 are drilled in ridges 80b between the grooves in the lower plate 94a. A diameter of the hole 95 is larger than that of a gas jetting hole formed in a base material, which is described below. A flat upper plate 94b made of SUS is also provided with the holes 95, each having a diameter larger than the hole formed in the base material, which is described below. The holes 95 drilled in the lower plate 94a and the holes 95 drilled in the upper plate 94b are arranged so as to correspond to each other, when the lower plate 94a and t...

example 1

[0079] A test block corresponding to the cooling block 80 was manufactured in accordance with the same procedures as those of the first embodiment (see, FIGS. 4A to 5C).

[0080] An amount of zinc applied to the surface of the first base material 8a was 30 g per 1 m2. A brazing material containing 80% or more by weight of Ni was applied to the surface of the second base material 8b. The cooling block manufactured as above is called Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com