Self-propelled concrete saw with forward motion speed control system

a technology of speed control system and self-propelled concrete saw, which is applied in the field of self-propelled concrete saw with forward motion speed control system, can solve the problems of reducing the cutting efficiency of the saw blade, affecting the operation generally not being advantageous to try to adjust the rotational speed of the power plant, so as to achieve the effect of maximizing the forward motion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

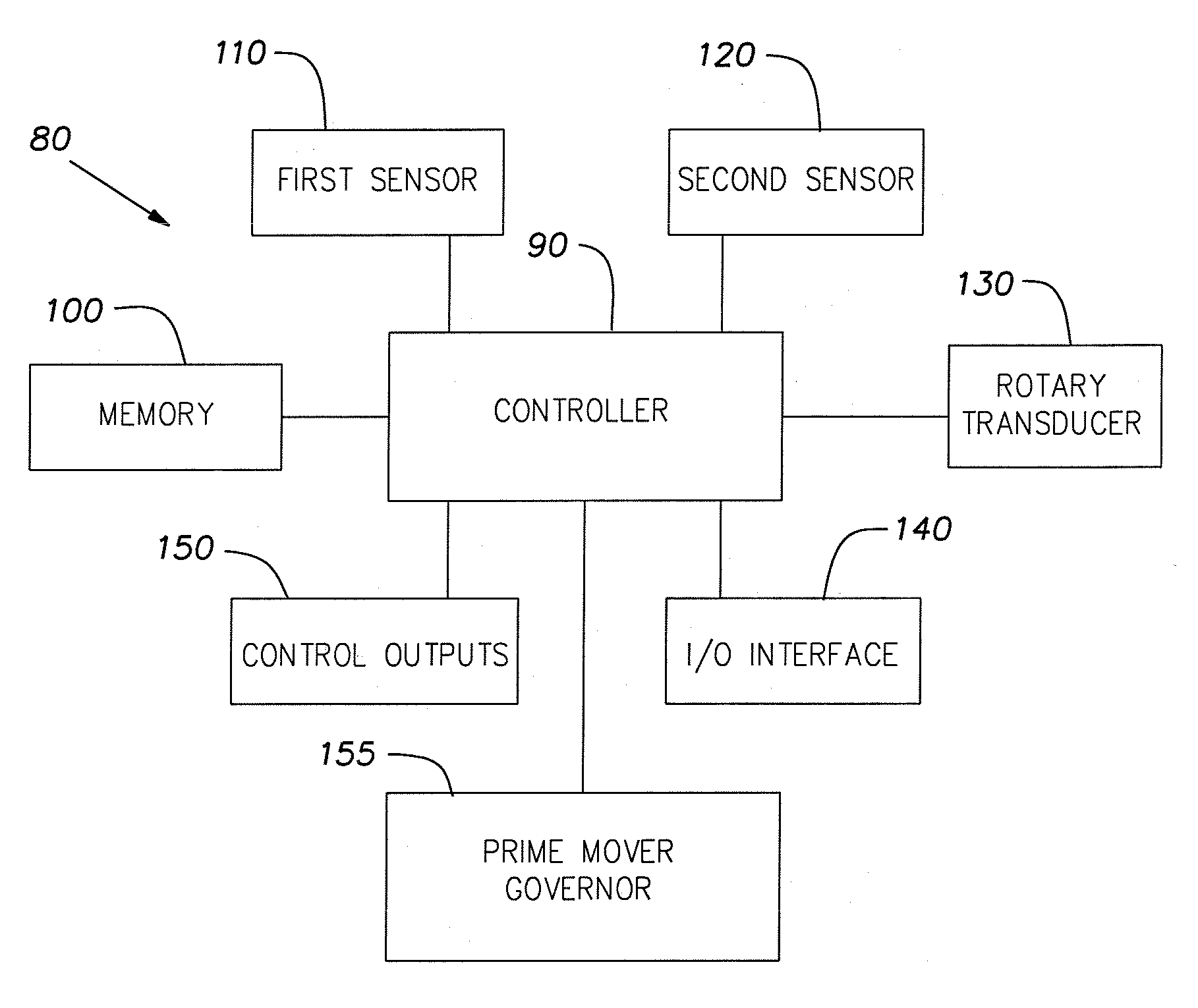

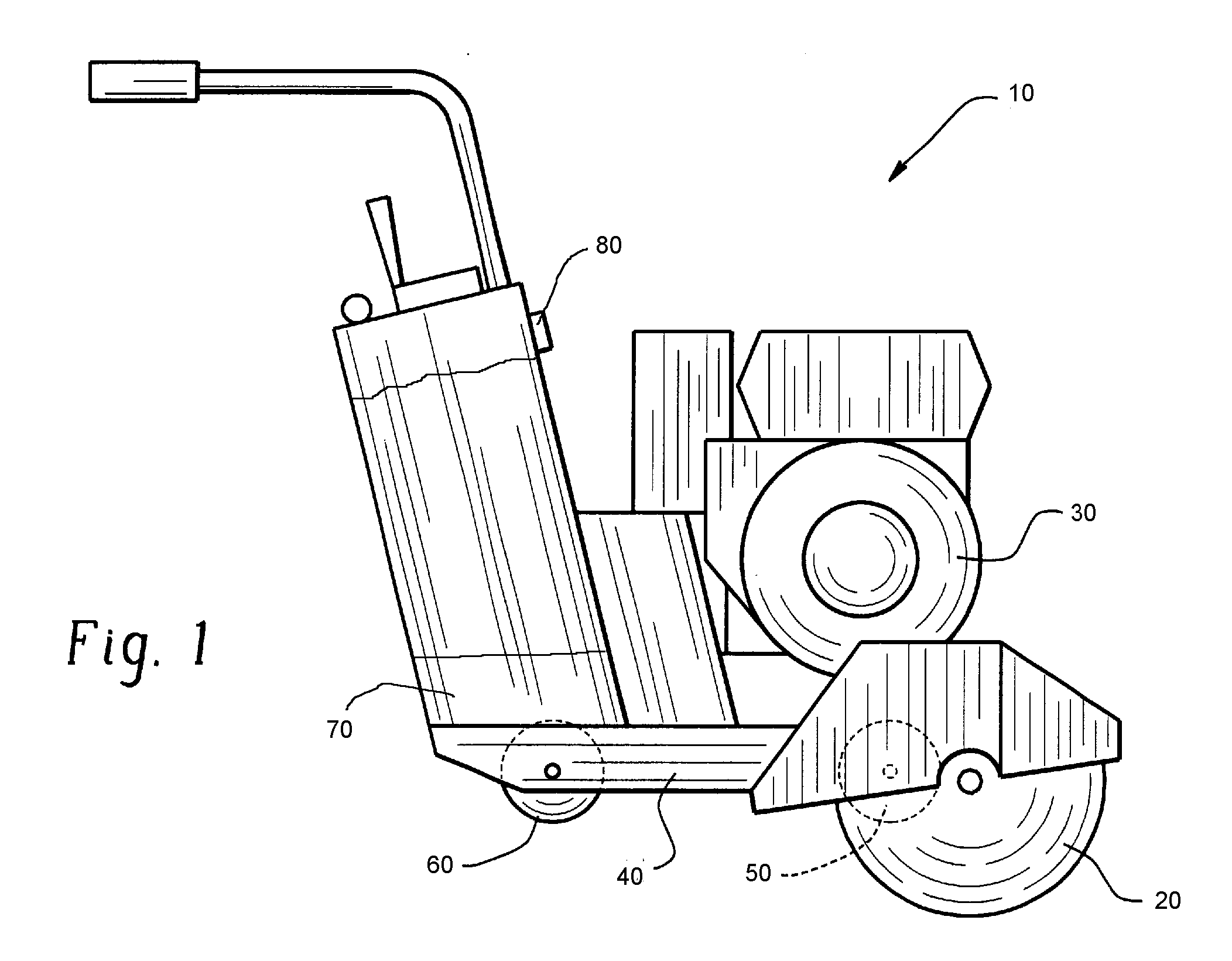

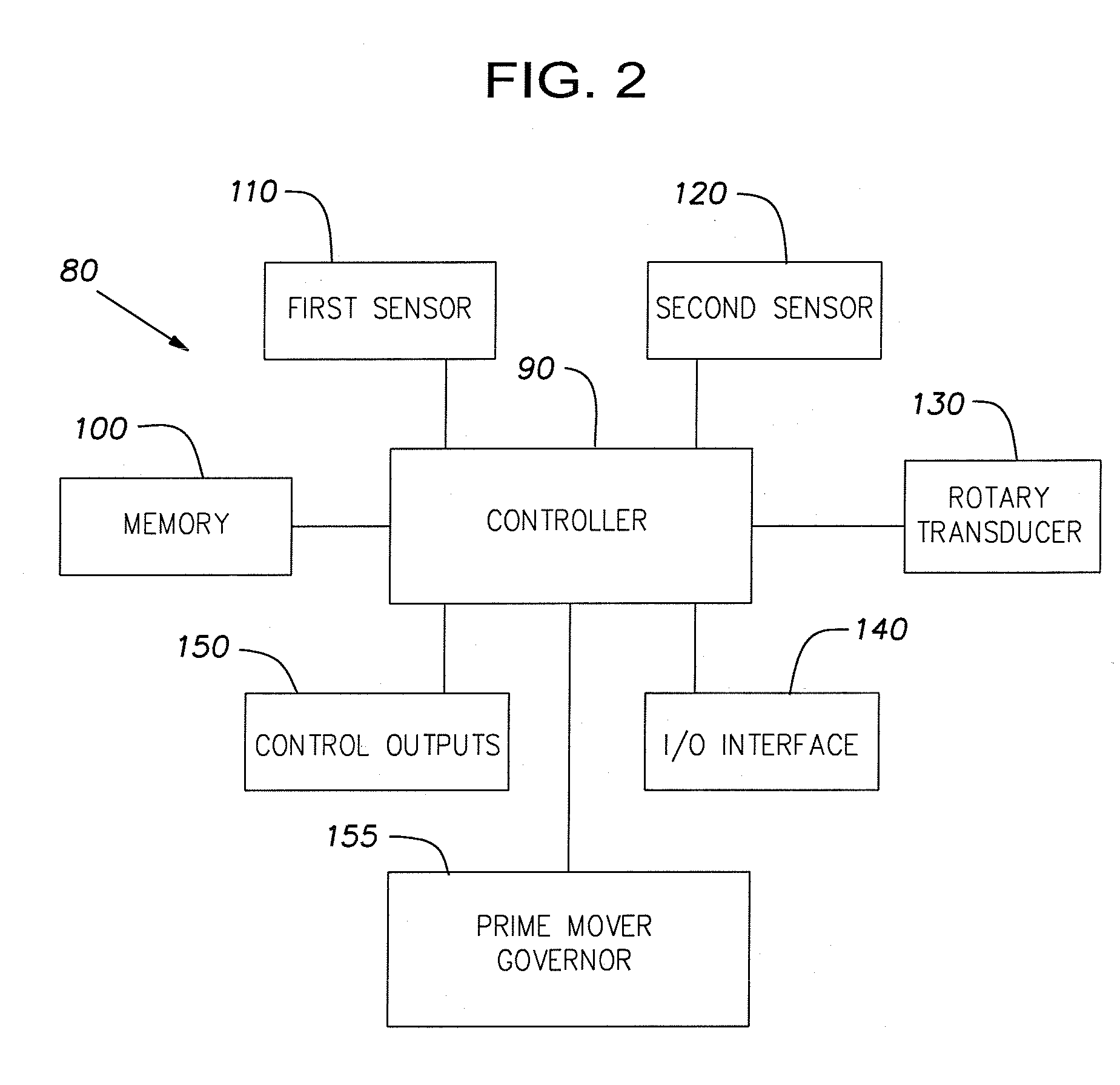

[0014] With reference to FIG. 1, a self-propelled concrete saw 10 comprises a diamond impregnated saw blade 20, a power plant (illustrated as an internal combustion engine) 30 and an associated drive system for providing rotational energy to the saw blade 20, a frame 40 for supporting the power plant 30, and a set of front wheels 50 and rear wheels 60 connected to the frame. In the schematically illustrated self-propelled concrete saw 10, the rear wheels 60 are driven in a conventional manner using a prime mover 70, typically a hydraulic drive system such as that shown in U.S. Pat. No. 5,810,448 which is incorporated herein by reference in its entirety. The forward motion speed of the self-propelled concrete saw 10 during a cutting or scoring operation is controlled by a control system 80. It will be appreciated that power plant 30 may comprise any one of a variety of power sources other than an internal combustion motor, such as, for example, a diesel motor or an electric motor.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com