Anti-wear device for a guide pivot of a variable-pitch vane of a turbomachine compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

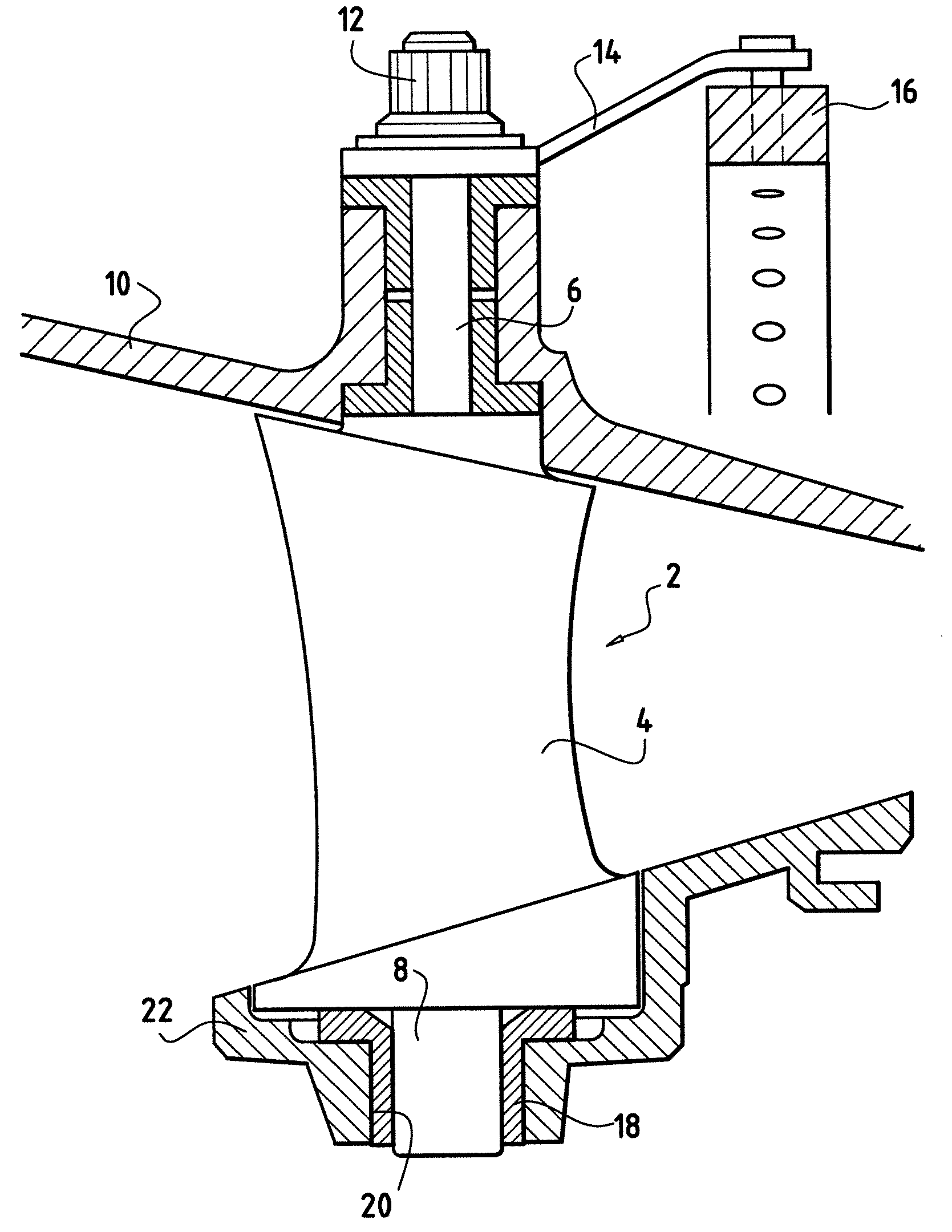

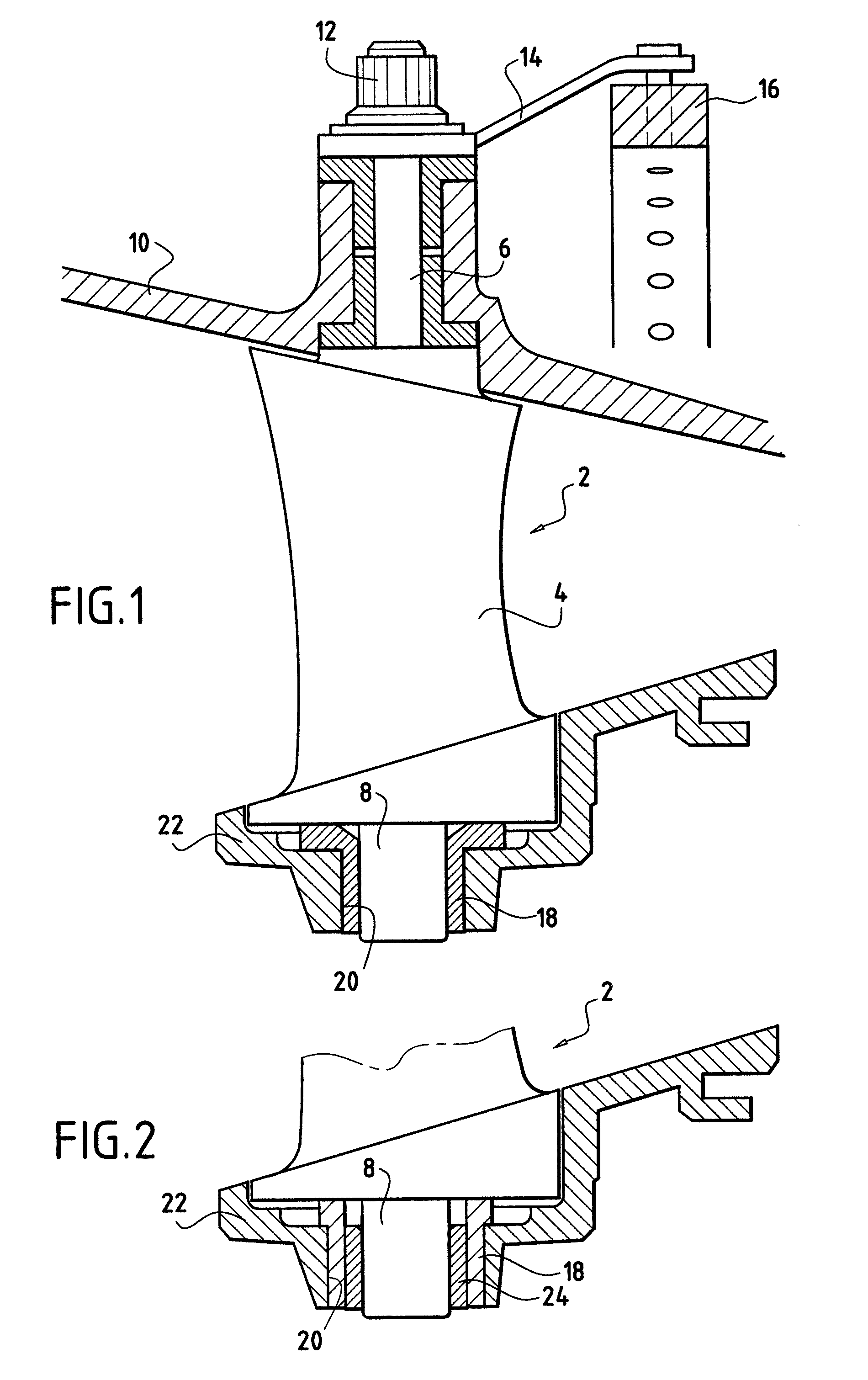

[0018]With reference to FIG. 1, the variable-pitch vanes 2 of the high pressure compressor of the turbomachine are distributed in circular stages disposed between stages of moving blades (not shown) that are secured to a rotor (not shown) of the turbomachine.

[0019]Each variable-pitch vane 2 of a circular stage is in the form of an airfoil 4 terminating at a radially outer end (or vane head) in a control pivot 6 (or top pivot), and at a radially inner end (or blade root) by a guide pivot 8 (or bottom pivot).

[0020]The control pivot 6 passes through a stator casing 10 of the turbomachine and co-operates with a member for controlling vane pitch. For this purpose, the control pivot 6 is terminated by a head 12 having engaged thereon one end of a control link 14 whose other end co-operates with a control ring 16.

[0021]The links 14 and the control ring 16 form the member for controlling the pitch of the vanes. Turning the control ring 16 about the axis of the turbomachine serves to turn th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com