Upgrading of peroxide treated petroleum streams

a technology of peroxide and petroleum stream, which is applied in the direction of hydrocarbon oil treatment, aromatic hydrocarbon hydrogenation, refining to change the structural skeleton of hydrocarbon, etc., can solve the problems of presenting corrosion problems, relatively expensive peroxide, and raising operational concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

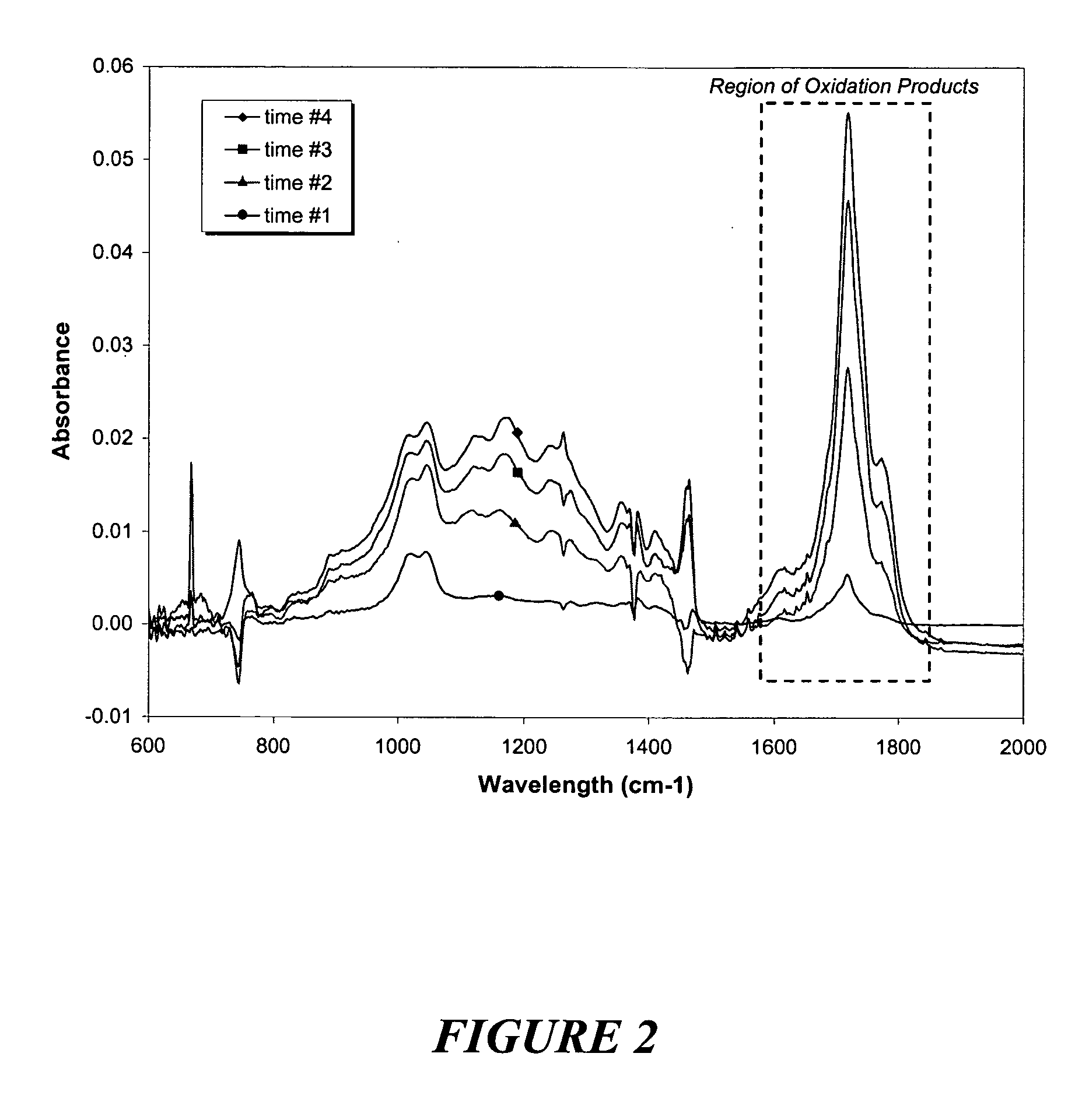

[0064] Experiments were conducted using a dewaxed HNN distillate as a test fluid and heated to 150° C. in the presence of air bubbling through the fluid. The oxidation products were measured by Fourier Transform Inferred Spectroscopy (FTIR) to determine the existence of oxidation products. Additionally a sample was heated in the presence of a nitrogen gas instead of air to determine the effect of any thermal degradation of the fluid under these test conditions. This sample was also measured by FTIR and used as a baseline reading. A subtraction spectra was generated at four different times during the oxidation experiments using the FTIR readings minus the baseline reading. The results are given in FIGS. 2 and 3, where FIG. 2 shows the FTIR subtraction spectra of four sequential samples undergoing oxidation across a wavelength ranging from 600 to 2000 cm−1. FIG. 3 shows FTIR subtraction spectra of four sequential samples undergoing oxidation reactions generally associated with the reg...

example 2

[0066] The current example uses real feeds of which are a combination of many species in their native environment. This example is directed to a series of runs comparing various catalyst / peroxide configurations as compared to a base case of a distillate undergoing extraction without the oxidation step (run 1 below). The series of runs include: [0067] 1. the heating of the distillate followed by extraction, [0068] 2. the addition of an oil-soluble catalyst, air and heat without peroxides followed by extraction, [0069] 3. the formation of in-situ peroxides, addition of air and heat without the oil soluble catalyst followed by extraction, [0070] 4. the formation of in-situ peroxides, addition of oil soluble catalyst, air and heat followed by extraction, [0071] 5. the formation of in-situ peroxides, addition of hydrogen peroxide, oil soluble catalyst, air, and heat followed by extraction.

[0072] The results of these runs have been shown in Table 1 as an improvement over the sulfur and n...

example 3

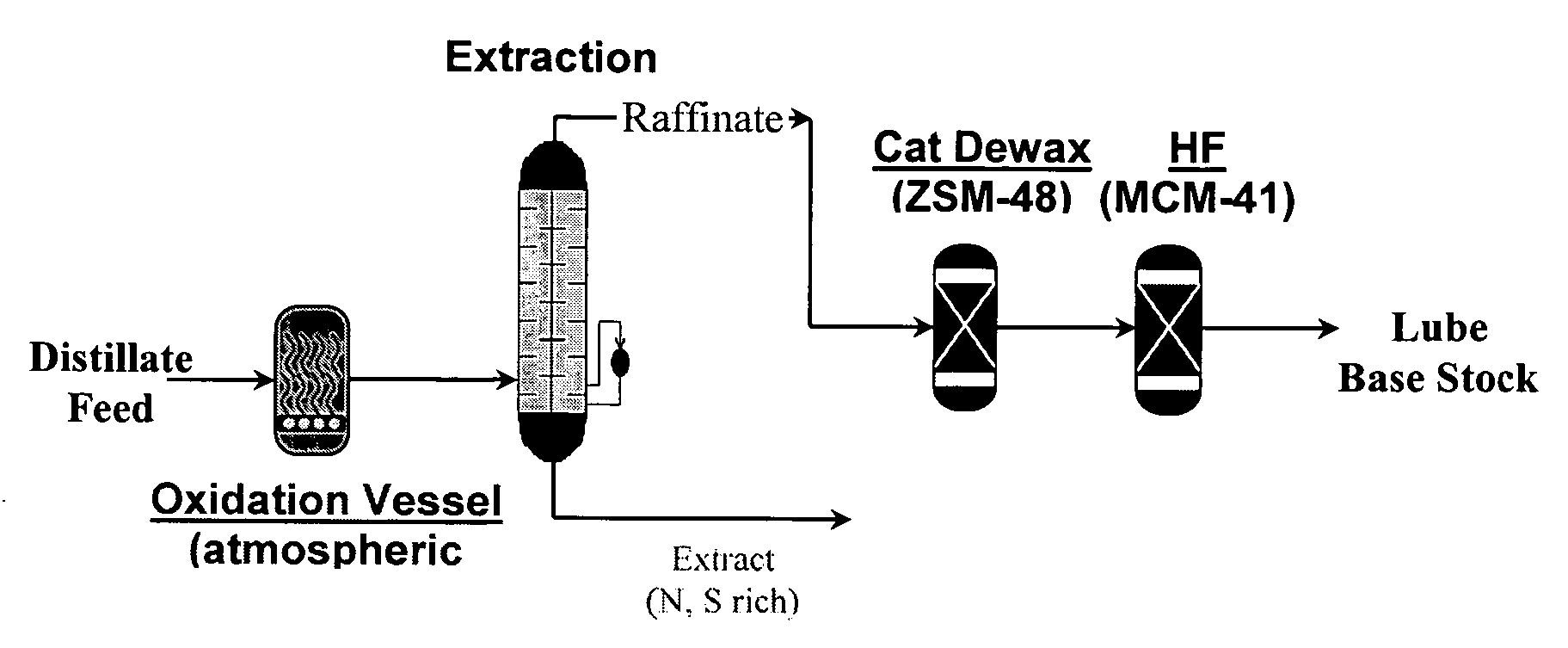

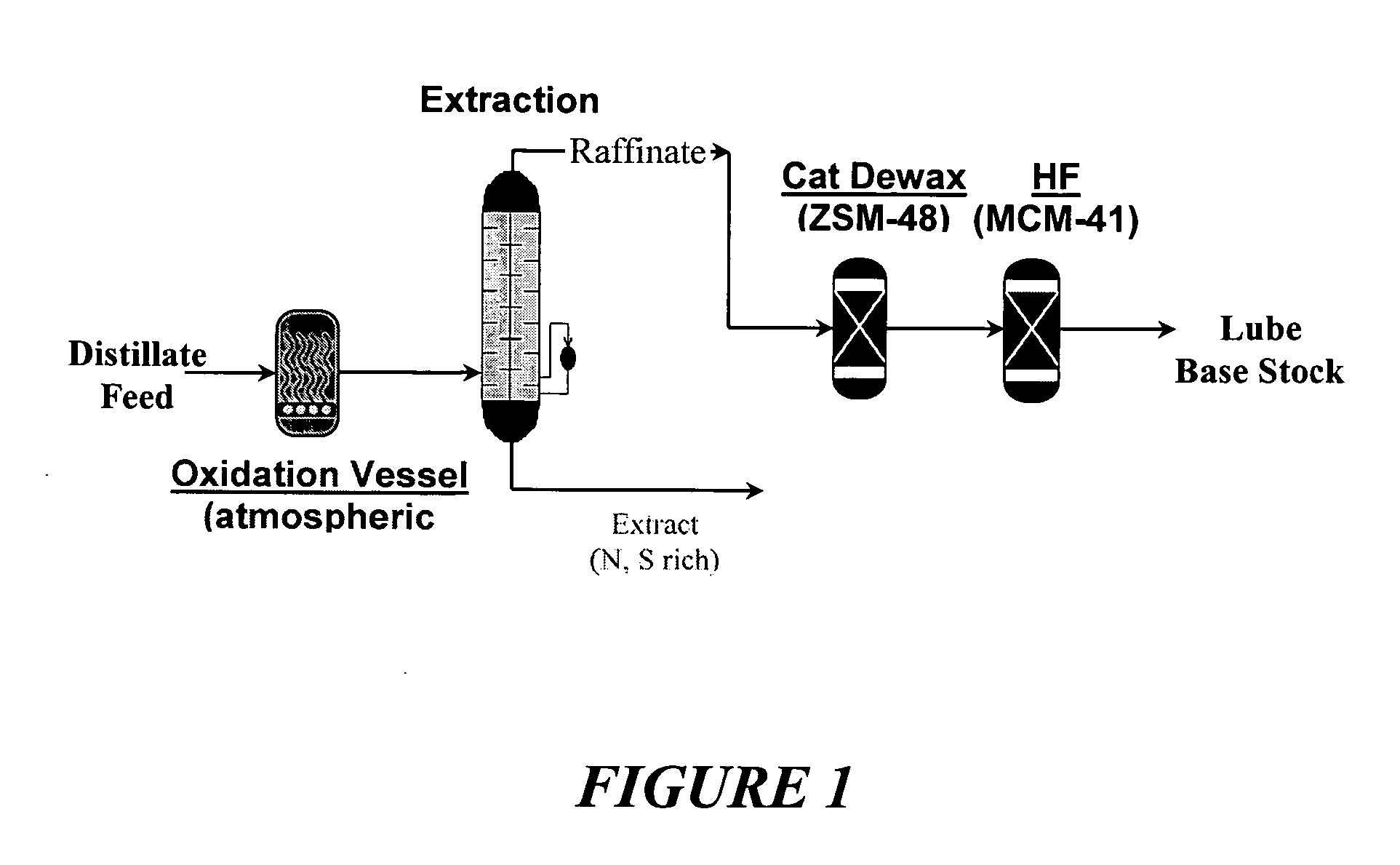

[0073] A set of experiments have been conducted using ZSM-48 followed by MCM-41 on hydrocracker bottoms with a pressure of 400 psig. The material contained approximately 25 wppm sulfur and 1.5 wppm nitrogen with a VI of 99. After hydroprocessing, the data showed a potential VI uplift of about 5 points with a conversion of 6-7 wt. % (FIG. 4). FIG. 4 is a graph showing the performance of ZSM-48 followed by MCM-41 at moderate operating pressures.

[0074] The yield loss is associated with the conversion of normal paraffinic species to iso-paraffinic species, beneficial to the VI. Similar data was generated at a pressure of 900 psig using various other feedstocks. These runs also showed significant VI improvements with minimal yield losses. These experiments provide support for an embodiment using air oxidation followed by solvent extraction followed by ZSM-48 catalytic dewaxing followed by MCM-41 aromatic saturation to improve basestock quality.

[0075] Additionally, this invention would ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com