Corrosion inhibitor

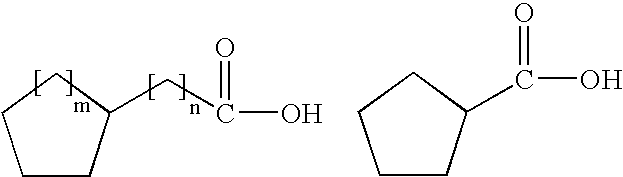

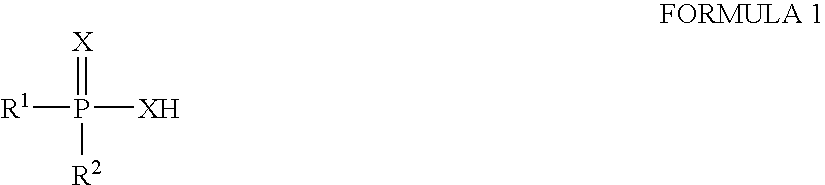

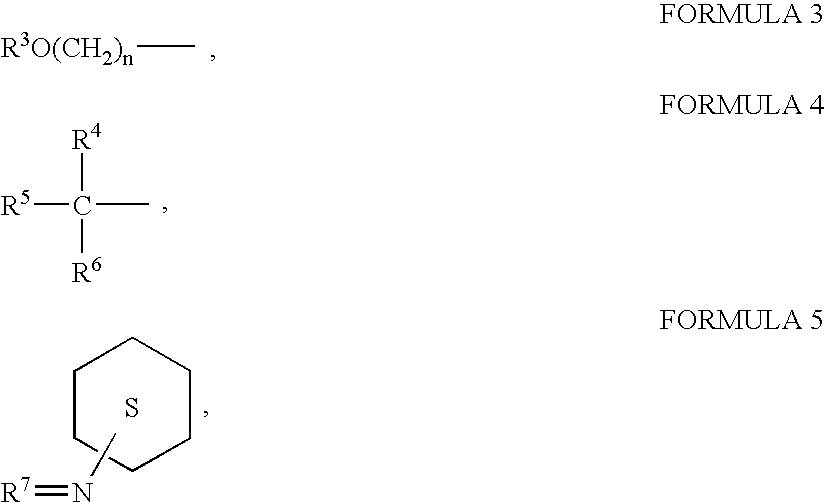

a corrosion inhibitor and inhibitor technology, applied in the field of corrosion inhibitors, can solve the problems of damage to the iron-containing metal surface of processing equipment, severe corrosion problems, and exacerbated corrosion problems, and achieve the effect of inhibiting naphthenic acid corrosion and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A test of the invention is performed by first determining the level of corrosion for a blank.

[0022] The procedure includes the step of adding 282 grams of mineral oil to a reaction flask. A test cell is sparged with nitrogen at a rate of from 10-20 mL / min for a period of 30 to 60 minutes with continuous stirring. The heaters are set at 288° C. and the test cell is sparged with 1 mol-percent H2S in nitrogen for the remainder of the test. The test procedure is run with a total acid number of 10 mg KOH, a temperature of 288° C., a run time of 24 hours, and 1 mol-percent of hydrogen sulfide in nitrogen, using C1018 carbon steel coupons. A “blank” is first tested, without corrosion inhibitor, to determine the amount of corrosion that occurs. About 20 g of commercial naphthenic acids having a total acid number of 151 are injected 30 minutes after the coupon is inserted into the test cell. Then a first test of the invention is done using another coupon and the same procedure, excep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com