Tube for heat exchanger and method of manufacturing the same

a technology of heat exchanger and tube, which is applied in the direction of indirect heat exchangers, laminated elements, light and heating apparatus, etc., can solve the problems of difficult to stably or uniformly form a crimped end on the tube wall, the inner fin is and the joining portions between the inner surface of the tube wall and the inner fin are likely to be displaced. , to achieve the effect of quality of joining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

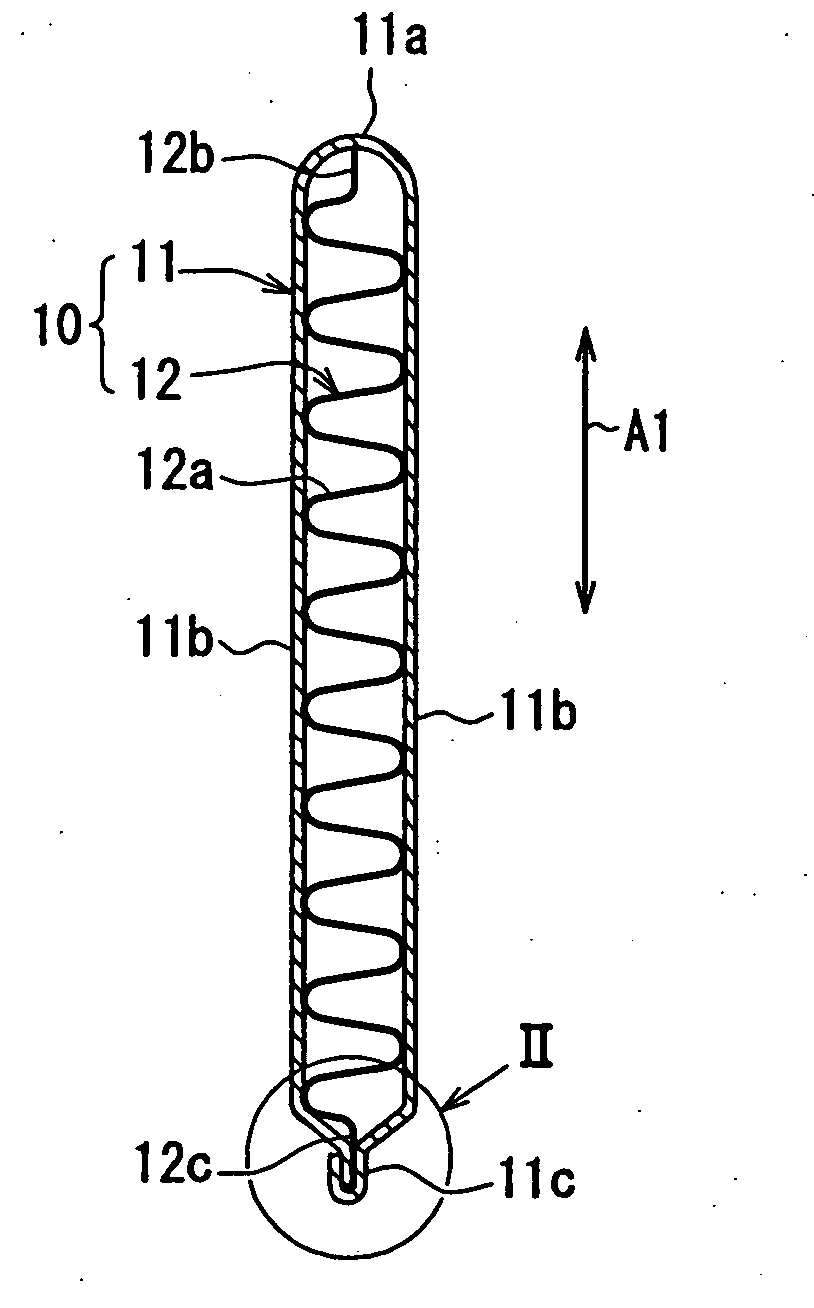

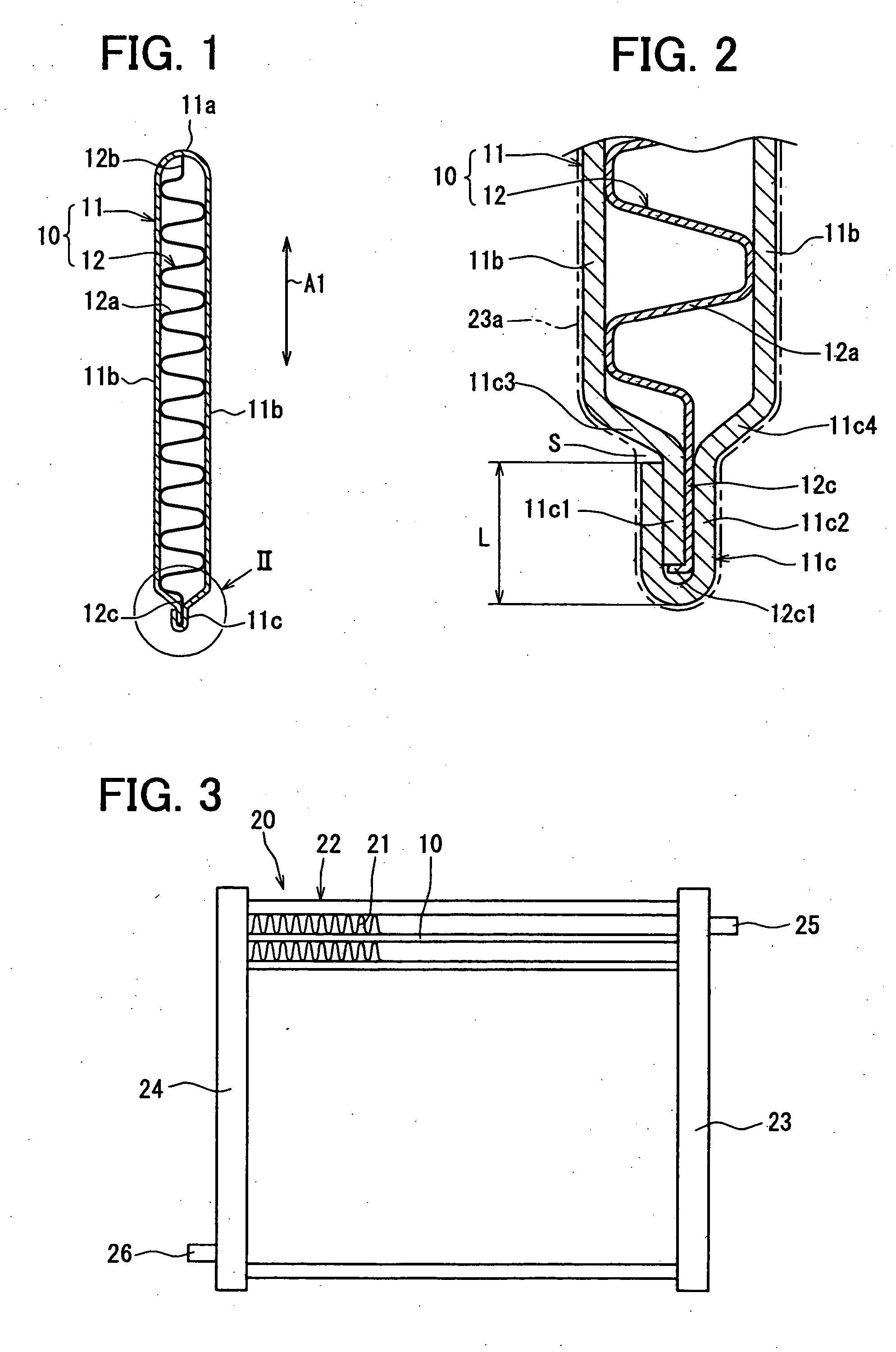

[0023] A first embodiment of the present invention will be described with reference to FIGS. 1 through 5. As shown in FIG. 1, an inner fin tube 10 of the first embodiment has a tube member 11 and an inner fin 12 inserted in the tube member 11. As shown in FIG. 3, the inner fin tube 10 is for example used as a tube of a heat exchanger 20 such as an evaporator of a refrigerating cycle.

[0024] The tube member 11 has a flat tubular shape. The tube member 11 is formed by folding a thin aluminum band plate. As shown in FIG. 1, in a cross-section defined in a direction perpendicular to a longitudinal direction of the tube member 11, the tube member 11 has a substantially elliptical shape. In FIG. 1, an arrow A1 denotes a direction parallel to a major axis of the elliptical shape.

[0025] The band plate is folded at a substantially middle portion thereof so that the tube member 11 has flat plate portions 11b and a bent portion 11a at ends of the flat plate portions 11b. The bent portion 11a ...

second embodiment

[0058] Next, a second embodiment of the present invention will be described with reference to FIGS. 6 and 7. In the second embodiment, inner fin tubes 10 have the same shape as the inner-fin tubes 10 of the first embodiment shown in FIG. 1. However, a method of manufacturing the inner fin tubes 10 is different from that of the first embodiment. FIG. 6 shows an early stage of the crimping step for crimping the first end portion 11c and the second end portion 11c2. FIG. 7 shows an intermediate stage of the crimping step.

[0059] In the second embodiment, the bent portion 12c1 of the inner fin 12 is formed at the same time as folding the second end portion 12c1 in the crimping step. In other words, the bent portion 12c1 is not formed in the inner fin forming unit 120.

[0060] In a condition that the inner fin 12 is inserted in the tube outer wall 11 in the inserting step, the second flat plate portion 12c is held between the first end portion 11c1 and the second end portion 11c2, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| L-shape | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com