Dual-sided substrate integrated circuit package including a leadframe having leads with increased thickness

a dual-sided substrate and integrated circuit technology, applied in the direction of solid-state devices, electric devices, basic electric elements, etc., can solve the problems of leadframe not being able to bridge the gap between contacts on circuit boards without some modification of leadframe, laminate structure requires costly, complex manufacturing processes, and defects. , the effect of less defect risk and less cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

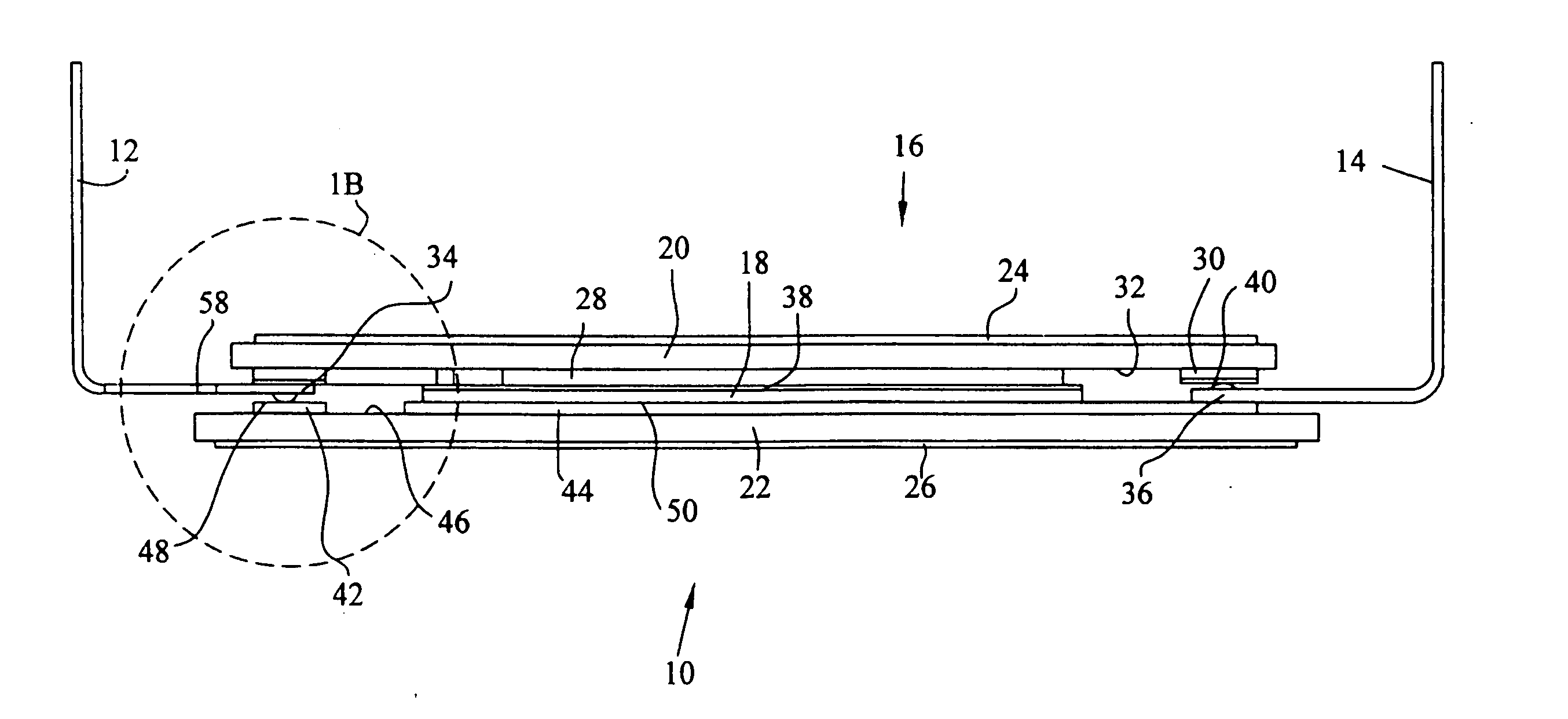

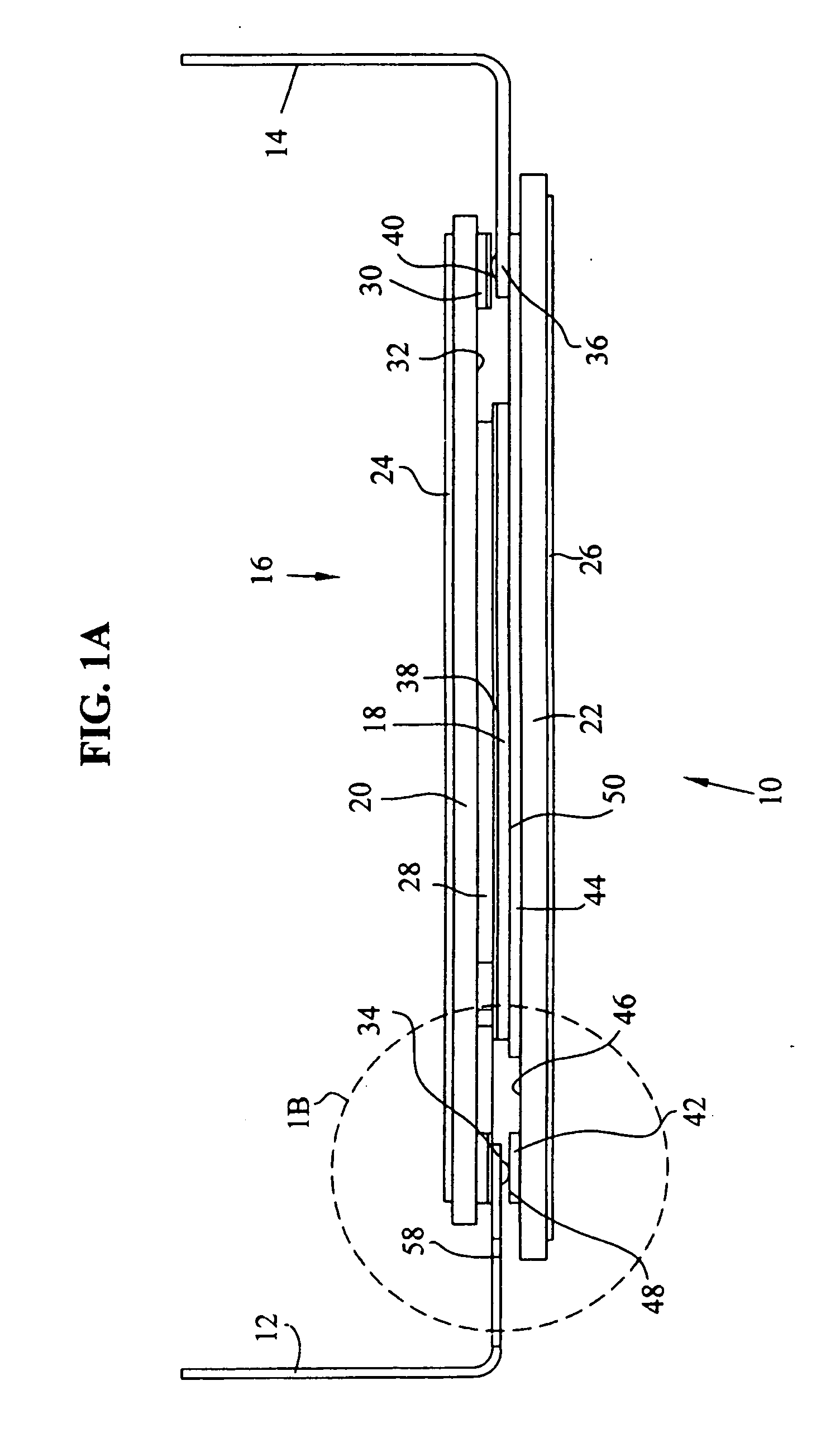

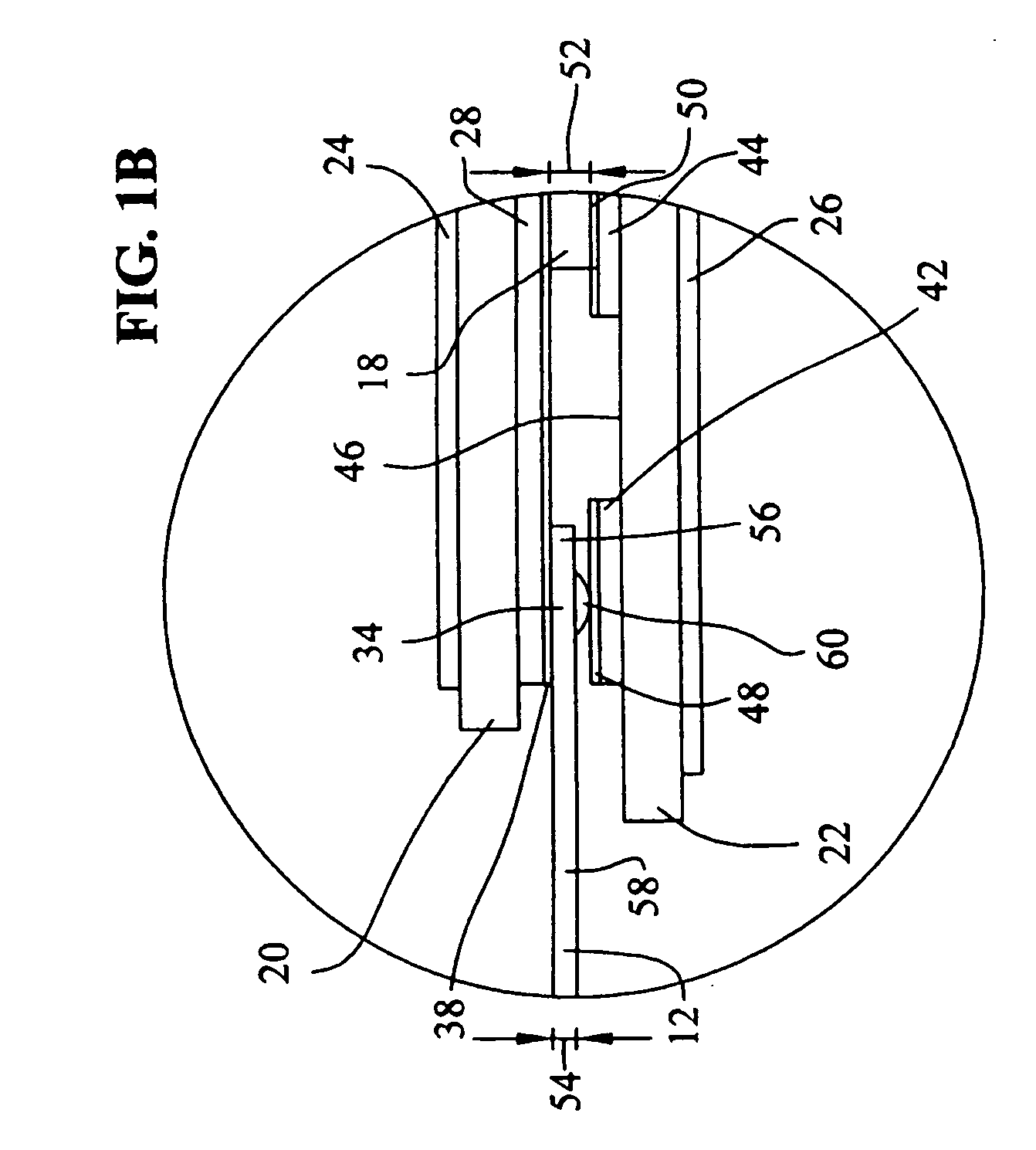

[0056] Referring now to the drawings, and particularly to FIG. 1A, there is shown one embodiment of an integrated circuit package 10 of the present invention, including leadframes 12, 14 in electrical communication with an integrated circuit 16. Integrated circuit 16 includes an integrated circuit die 18 formed of a semiconductor material. Die 18 is sandwiched between non-conductive substrates 20, 22, which can be formed of a ceramic material.

[0057] Each of substrates 20, 22 can include a respective layer of solderable material 24, 26 on the outer surfaces thereof. Pressure attached applications may not require solderable material 24, 26 on the outer surface. Elimination of solderable material 24 and 26 reduces the thermal resistance and device temperature.

[0058] Electrically conductive bonded copper elements 28, 30 are attached to an inner surface 32 of substrate 20. In the particular embodiment shown in FIG. 1A, element 28 is in the form of a substrate, while element 30 may bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com