Method for forming a film of lithium metal or lithium alloys and an apparatus for the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

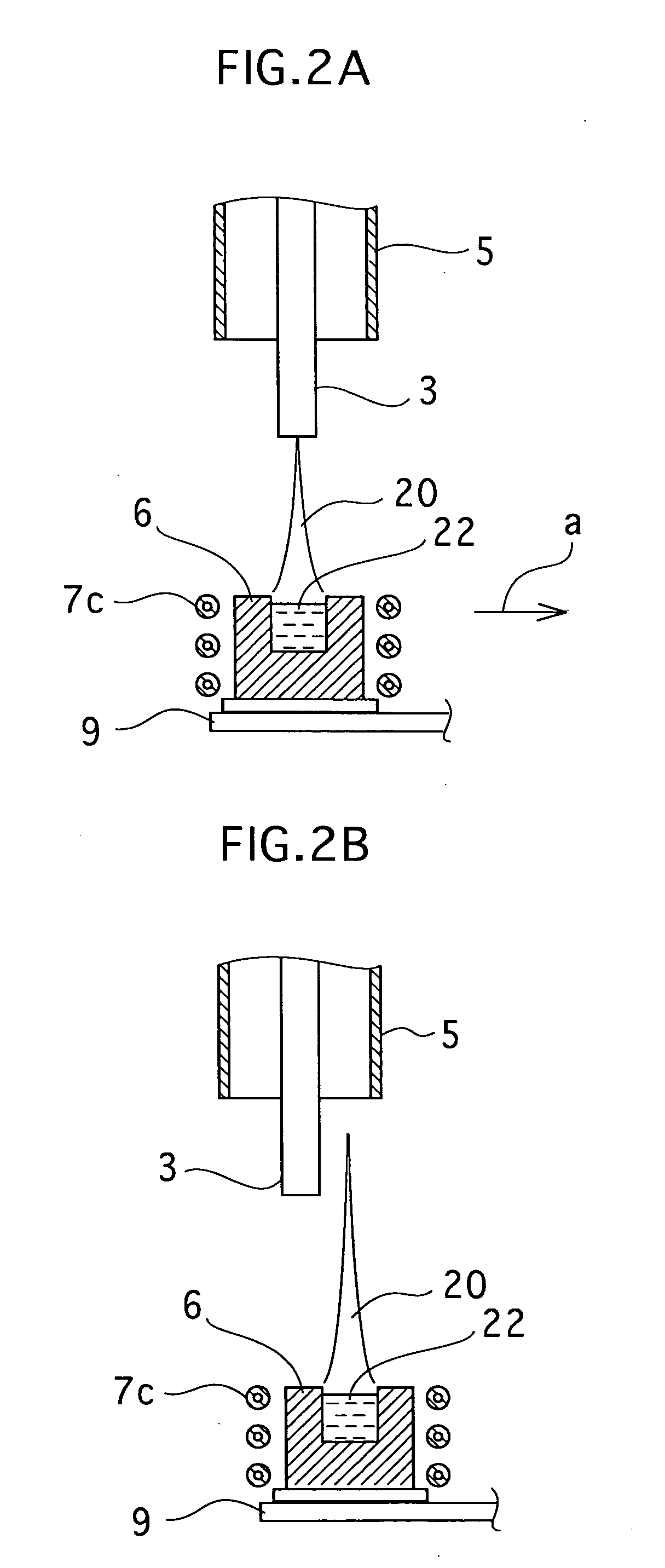

[0037]FIG. 1 shows a gas deposition apparatus A of the first embodiment. Generally, it consists of an ultra fine particle evaporation chamber 1, a transfer pipe 3, and a film forming chamber 2, which are arranged in a vertical direction. A crucible 6 which is made of, for example, tantalum, the inner diameter and the outer diameter of which are equal to 38mm(p and 40 mmφ. respectively, is arranged in the ultra fine particle evaporation chamber 1. The height of the crucible 6 is equal to 40 mm. Evaporation material 22 (Li) is contained in the crucible 6. An electromagnetic coil 7C for heating inductively lithium 22 is wound around the crucible 6. The coil 7C is connected to a radio (high) frequency (150 kHz) electric power source 7 which is arranged outside of the ultra fine particle evaporation chamber 1.

[0038] A helium (He) gas is introduced into the ultra fine particle evaporation chamber 1 through a mesh-filter type introducing port M, so that the ultra fine particle evaporation...

second embodiment

[0063]FIG. 3 shows a gas deposition apparatus B of the second embodiment. The parts which correspond to those in FIG. 1, are denoted by the same, but primed, reference numerals. Generally, it consists of an ultra fine particle evaporation chamber 1′, a transfer pipe 3′, and a film forming chamber 2′, which are arranged in a vertical direction. A crucible 6′, the inner diameter of which is equal to 5.0 mm, is arranged in the ultra fine particle evaporation chamber 1′. Evaporation material 22′ (Li) is contained in the crucible 6′. An electromagnetic coil 7C′ for inductively heating lithium in the crucible 6′ is wound around the crucible 6′. The coil 7C′ is connected to a radio (high) frequency electric power source 7′ which is arranged outside of the ultra fine particle evaporation chamber 1′.

[0064] A helium (He) gas is introduced into the ultra fine particle evaporation chamber 1′ through a mesh-filter type introducing port M′, so that the ultra fine particle evaporation chamber 1′ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com