Production method of offset-shaped fins, fins, and method and apparatus for changing pitch of fins

a production method and fin technology, applied in the direction of lighting and heating equipment, laminated elements, tubular elements, etc., can solve the problems of difficult roll molding practice, material damage to rollers, and inability to achieve heat transfer efficiency improvement, etc., to achieve stably and continuously produced fins, the effect of reducing production cost and installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

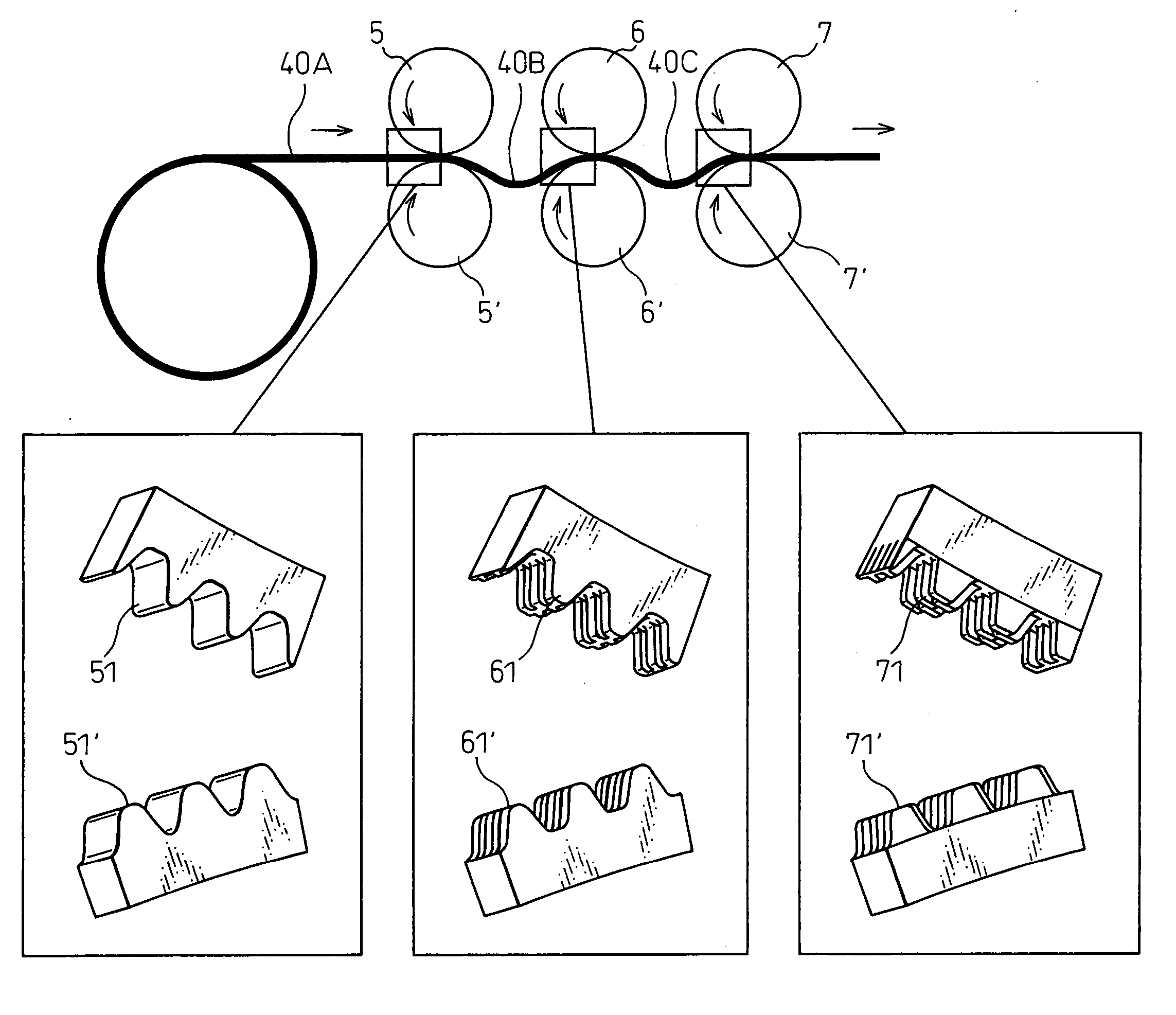

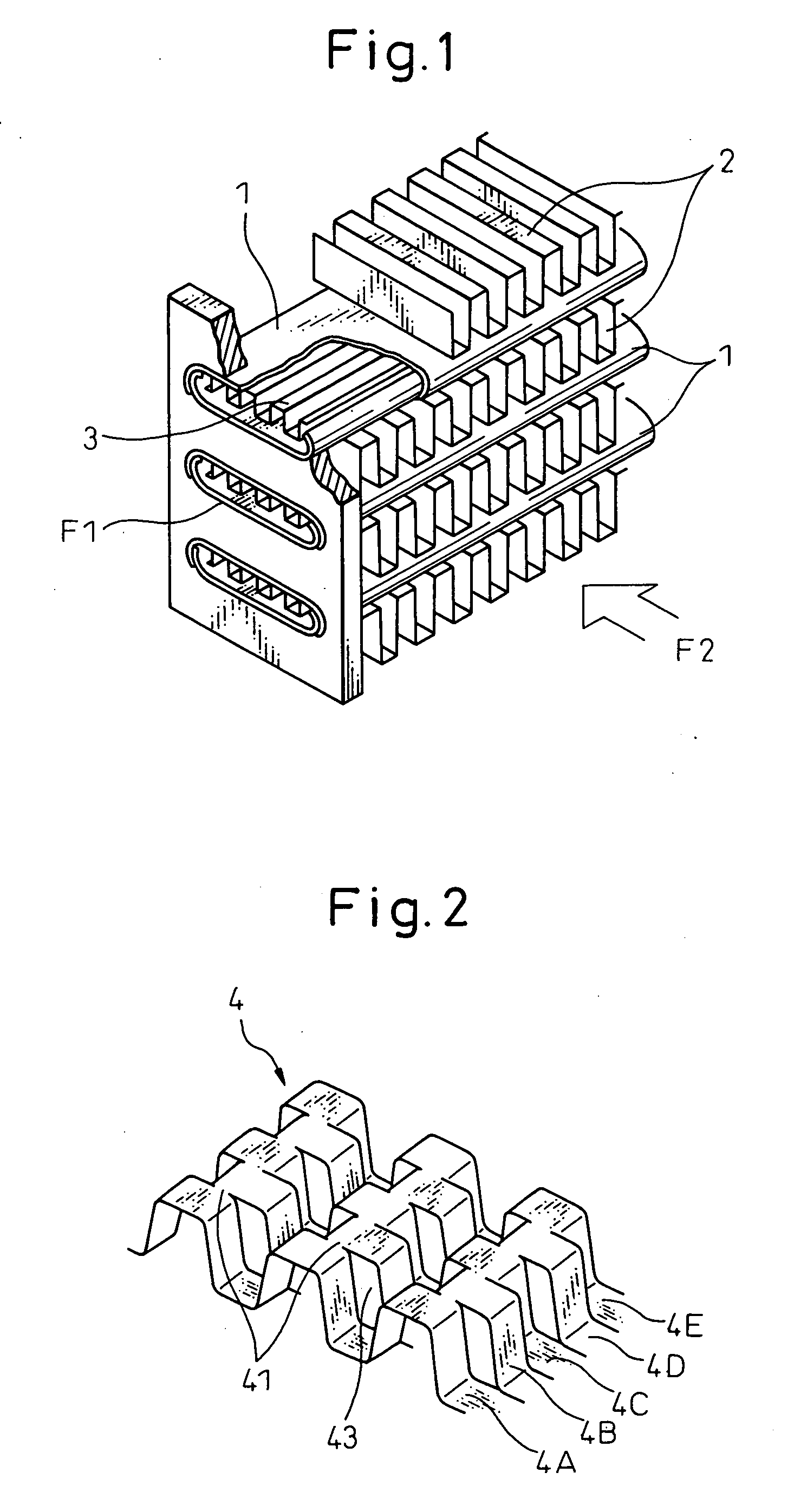

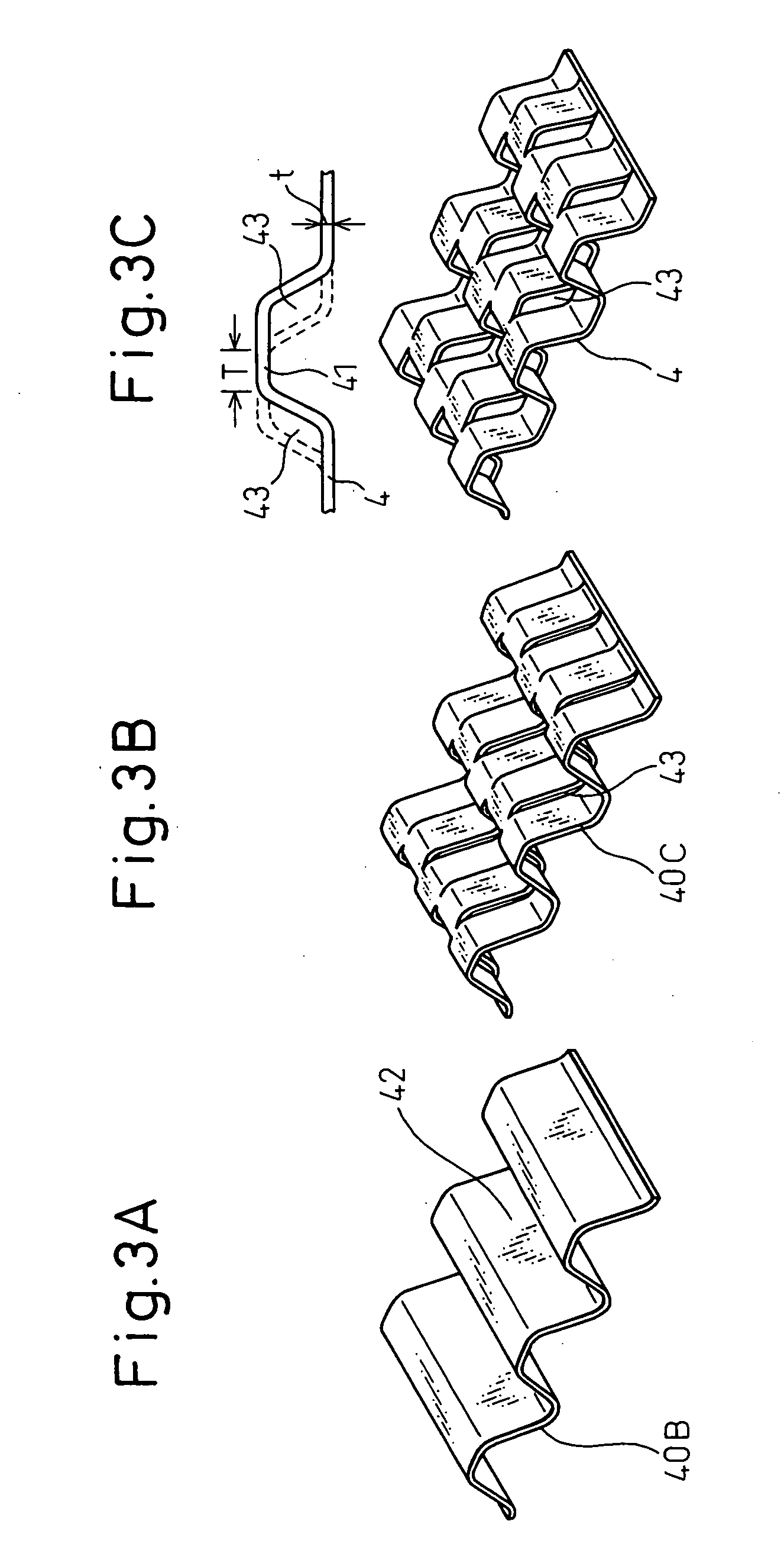

[0038] A production method of offset-shaped fins according to the present invention and the offset-shaped fins produced by this production method will be explained hereinafter with reference to the accompanying drawings. FIG. 1 shows an example of a stacked type heat exchanger. In the stacked type heat exchanger, a plurality of heat transfer tubes 1 are extended in parallel with one another between a pair of headers not shown, and corrugate fins (outer fins) 2 are arranged between the heat transfer tubes 1. In other words, a heat exchange core portion is formed as the heat transfer tubes 1 and the outer fins 2 are alternately stacked. Consequently, heat exchange is made between a heat exchange medium F1 flowing inside the heat transfer tubes 1 and a heat exchange medium F2 passing through the outer fins 2 outside the heat transfer tubes 1.

[0039] In this case, it has been customary to insert and arrange inner fins 3 into the heat transfer tube 1, as shown in FIG. 1, in order to prom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com