Zone settling aid and method for producing dry diluted bitumen with reduced losses of asphaltenes

a technology of asphaltene and zone settling, which is applied in the production of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of increasing the operational risk of fire, environmental hazard, financial liability, and underflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

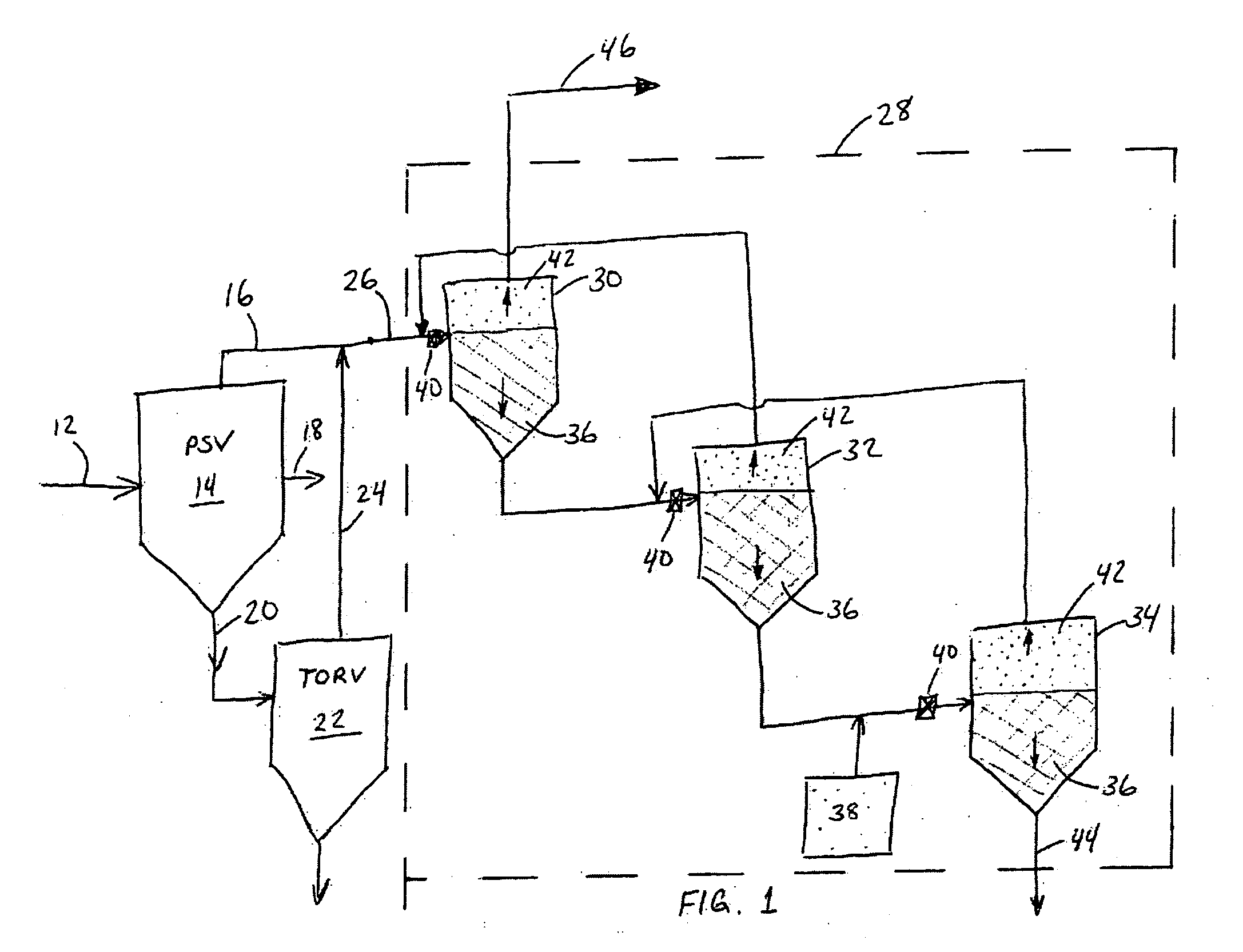

Method used

Image

Examples

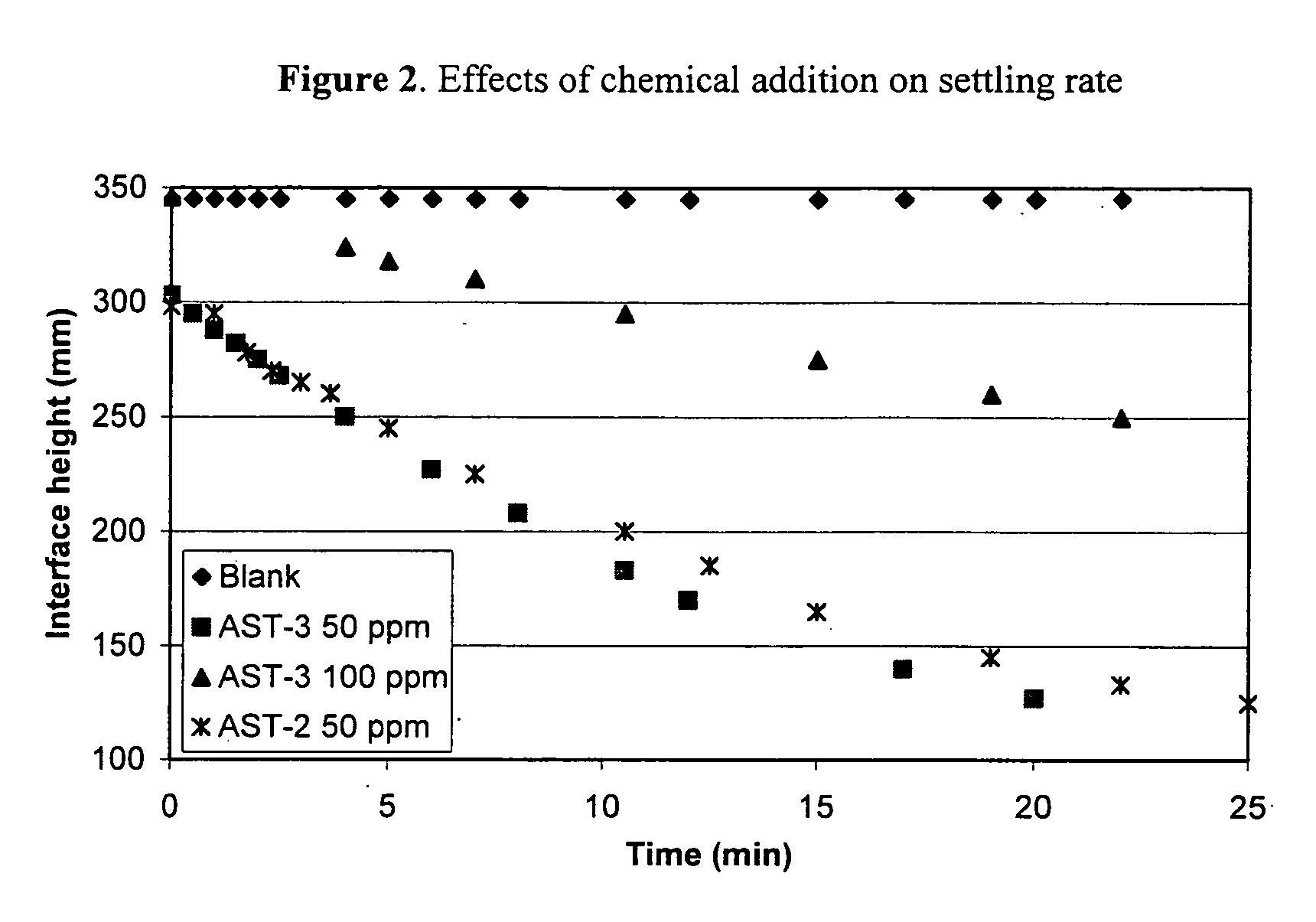

example 1

[0045] A bitumen froth containing approximately 60% bitumen, 30% water and 10% solids was mixed with a hydrocarbon diluent consisting of 30% toluene and 70% heptane to simulate naphtha. The diluent to bitumen ratio (D:B) of the diluted bitumen was 0.75 and the temperature of the mixture was 50° C.

[0046] A first zone settling aid (AST-3) was prepared from a polyethylene amine acceptor having on average nine active hydrogen atoms, a first propylene oxide block of about 1451 daltons per branch, and a second ethylene oxide block of about 435 daltons per branch. The resulting polyoxyalkylate has a molecular weight of about 17,000 daltons. The first zone settling aid was mixed with diluted bitumen at 50 ppm and 100 ppm concentrations, separately.

[0047] A second zone settling aid (AST-2) was prepared from a triol acceptor having three active hydrogen atoms that were used to prepare a sequential polymer having three branches. Each branch had a first propylene oxide block of about 3000 dal...

example 2

[0050] A zone settling aid according to the invention was prepared with a sorbitol acceptor having six active hydrogen atoms, a first PO block of about 1000 daltons for each of the six branches, and a second EO block of about 300 daltons per branch. The total molecular weight of the zone settling aid was about 7,800 daltons.

[0051] A 404 gram sample of bitumen froth was 60% bitumen (246 grams bitumen), 30% water and 10% solids. The froth was heated to 85° C. and stirred for three minute to homogenize the sample. To achieve a diluent:bitumen ratio of 0.65, about 160 grams of naphtha was heated to 85° C. and added to the froth with stirring for two minutes at 1000 RPM with a paint stirrer. Then, 0.57 ml of a 10% solution of the zone settling aid was added to the diluted bitumen with three minutes of stirring. Upon settling, about 300 grams of dry, diluted bitumen was removed from the top of the settler for a recovery of about 182 grams of bitumen. The diluted bitumen had a water conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention time | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com