Method of Making Perfluorocarbon Emulsions With Non-Fluorinated Surfactants

a technology of fluorinated surfactants and emulsions, which is applied in the direction of halogenated hydrocarbon active ingredients, hair cosmetics, transportation and packaging, etc., can solve the problems of low stability, low reactivity, low stability, etc., and achieve the effect of simple and low energy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

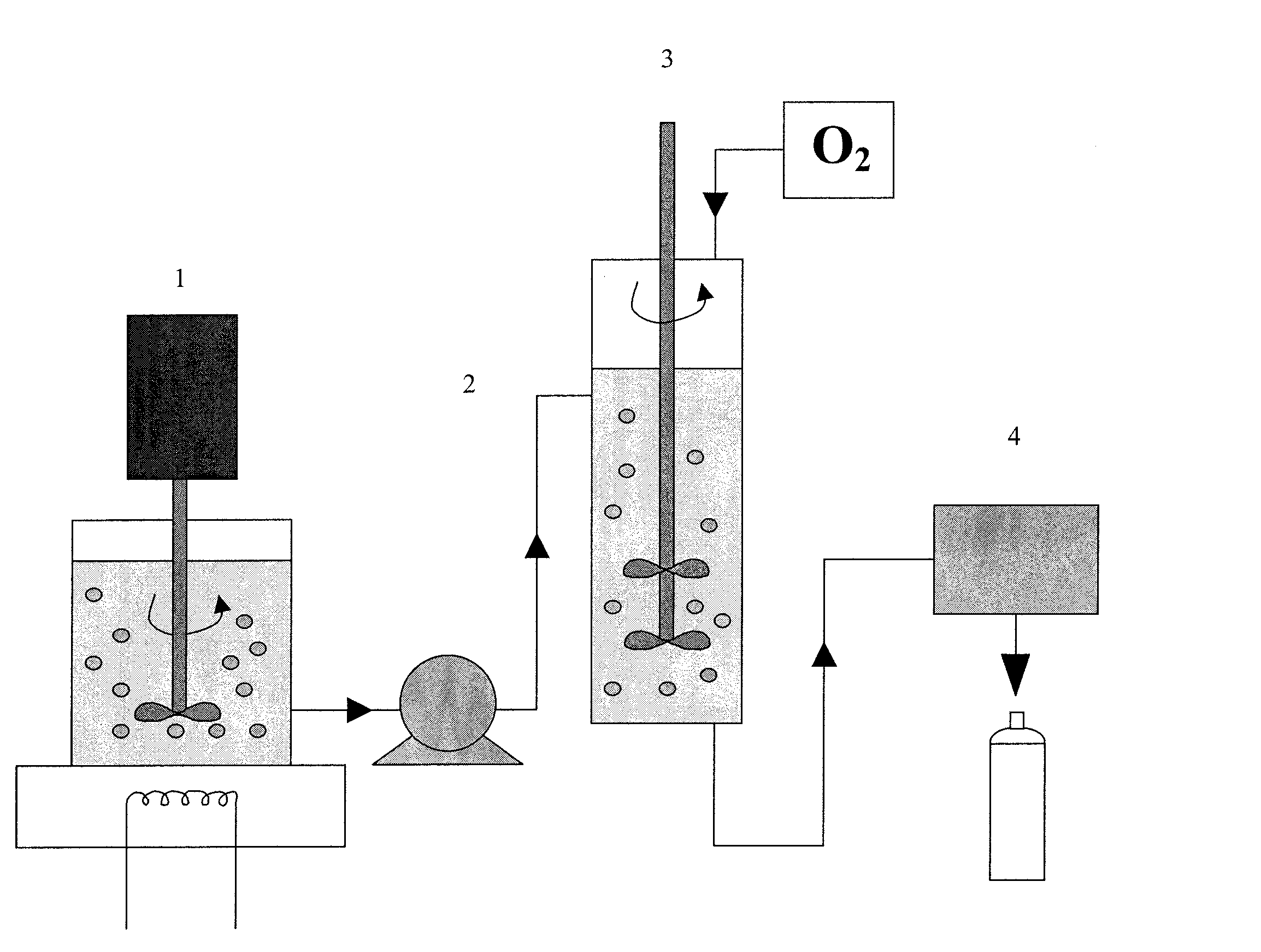

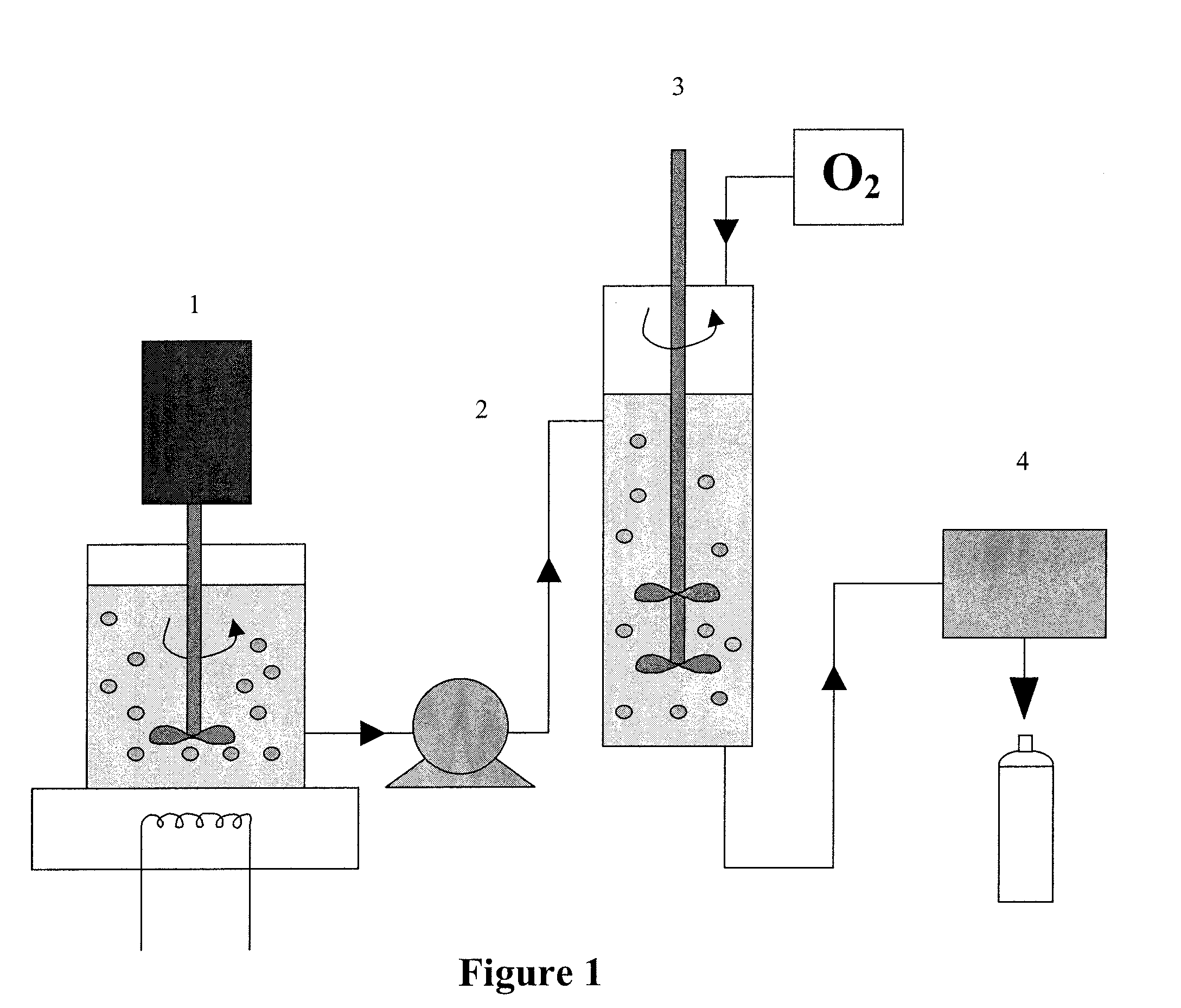

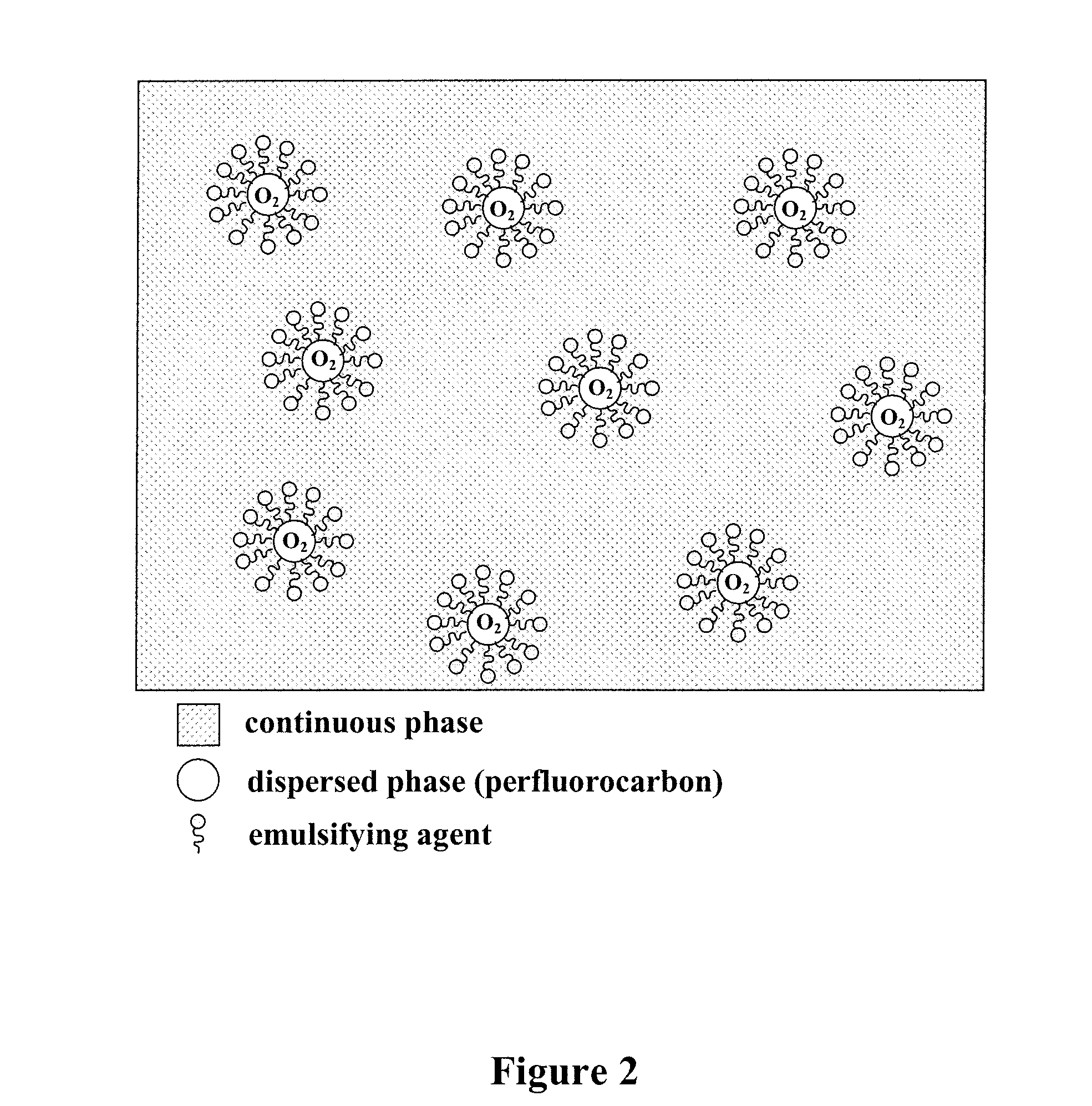

Method used

Image

Examples

example 1

[0108]

Preparation of the FC emulsionIngredients% (wt / wt)A Water42B Glycerin12C Hydrogenated Phospholipid4.5D Cetyl alcohol0.6E Stearyl alcohol0.6F Polysorbate 600.5G Perfluorodecalin39.5H Tocopheryl acetate0.4

A is mixed into B. The mixture is heated to 70° C. in a reaction vessel with agitation. When the temperature reaches 70° C., C is added to the mixture at 70° C. with agitation. An overhead stirrer is used to conduct this step. After C is uniformly dispersed in the mixture, D, E and F are added with continued agitation. When all of the above ingredients are uniformly dispersed, G is added slowly at a controlled rate with agitation. When all G has been added, H is added while maintaining the temperature at 70° C. The mixture is cooled slowly to room temperature. Alternatively, prior to cooling, the mixture may be subjected to homogenization and then cooled slowly to room temperature.

example 2

[0109]

Preparation of alternate FC emulsionIngredients% (wt / wt)AWater42.5BPropylene Glycol30CHydrogenated Phospholipid4.4DCetyl alcohol0.3EStearyl alcohol0.3FPolysorbate 600.2GGlyceryl stearate, PEG-75 stearate,0.8ceteth-20, steareth-20(Emulium Delta, Gattefosse, France)HPerfluorodecalin20ITocopheryl acetate0.5JDimethicone0.7KBenzyl alcohol0.4LMethyl paraben0.1MPropyl paraben0.05NHyaluronic acid1

A is mixed into B. The mixture is heated to 70° C. in a reaction vessel with agitation. When the temperature reaches 70° C., C is added to the mixture at 70° C. with agitation. An overhead stirrer is used to conduct this step. After C is uniformly dispersed in the mixture, D, E, F and G are added with continued agitation. When all of the above ingredients are uniformly dispersed, H is added slowly at a controlled rate with agitation. When all H has been added, I and J are added while maintaining the temperature at 70° C. The mixture is cooled slowly to room temperature. While the mixture is ...

example 3

[0110]

Preparation of alternate FC emulsionIngredients% (wt / wt)AWater48BPropylene Glycol34CHydrogenated Phospholipid4DCetyl alcohol0.4EStearyl alcohol0.4FPolysorbate 600.3GGlyceryl stearate, PEG-75 stearate,1ceteth-20, steareth-20(Emulium Delta, Gattefosse, France)HPerfluorodecalin10ITocopheryl acetate0.8JDimethicone0.5KBenzyl alcohol0.4LMethyl paraben0.1MPropyl paraben0.05

A is mixed into B. The mixture is heated to 70° C. in a reaction vessel with agitation. When the temperature reaches 70° C., C is added to the mixture at 70° C. with agitation. An overhead stirrer is used to conduct this step. After C is uniformly dispersed in the mixture, D, E, F and G are added with continued agitation. When all of the above ingredients are uniformly dispersed, H is added slowly at a controlled rate with agitation. When all H has been added, I and J are added while maintaining the temperature at 70° C. The mixture is cooled slowly to room temperature. While the mixture is cooling, K, L and M are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com