Enhancement of light extraction with cavity and surface modification

a technology of surface modification and light extraction, applied in the manufacture of electrode systems, electric discharge tubes/lamps, discharge tubes luminescnet screens, etc., can solve the problem that the addition of lenses on the outside of the substrate does not provide extra benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

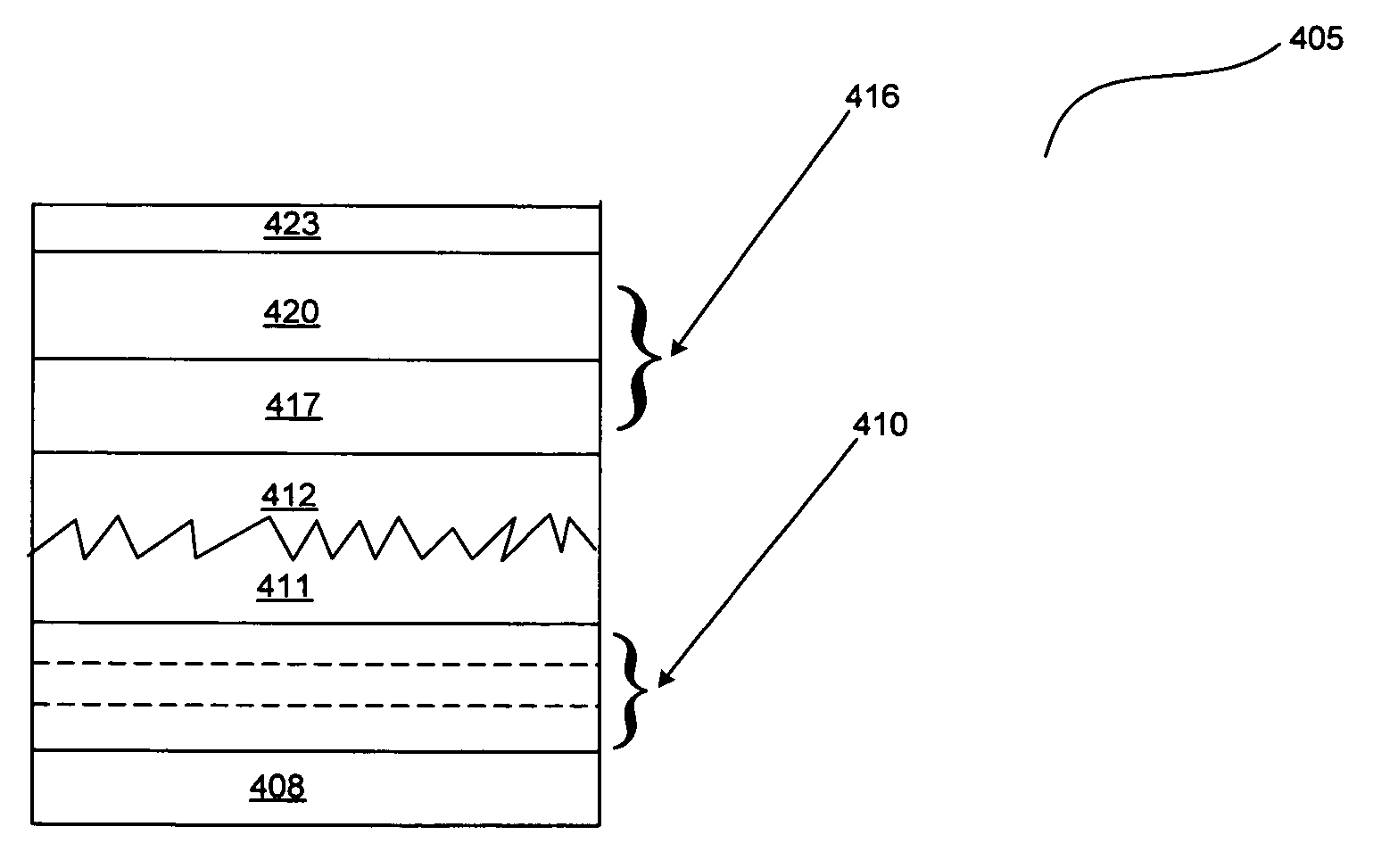

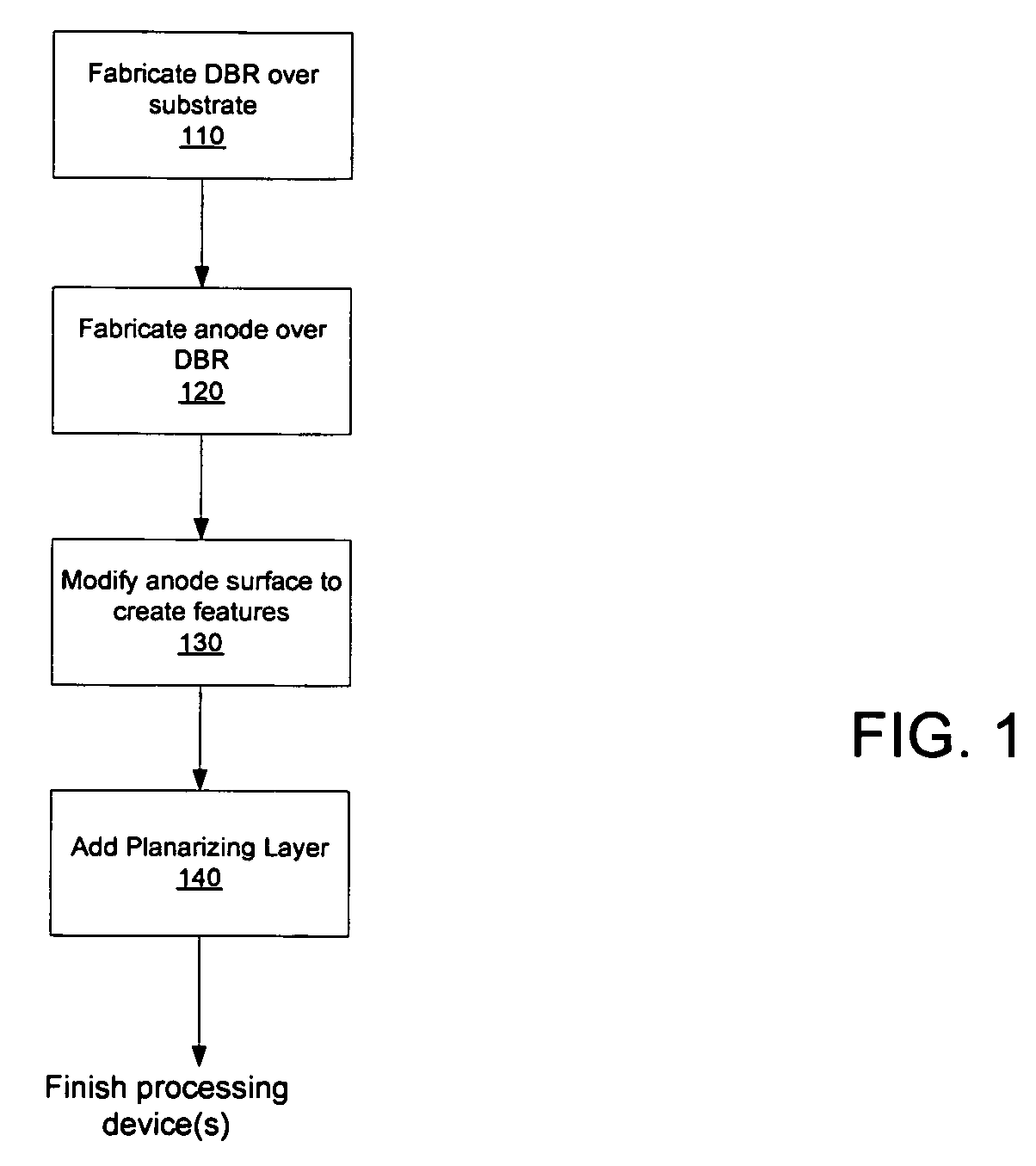

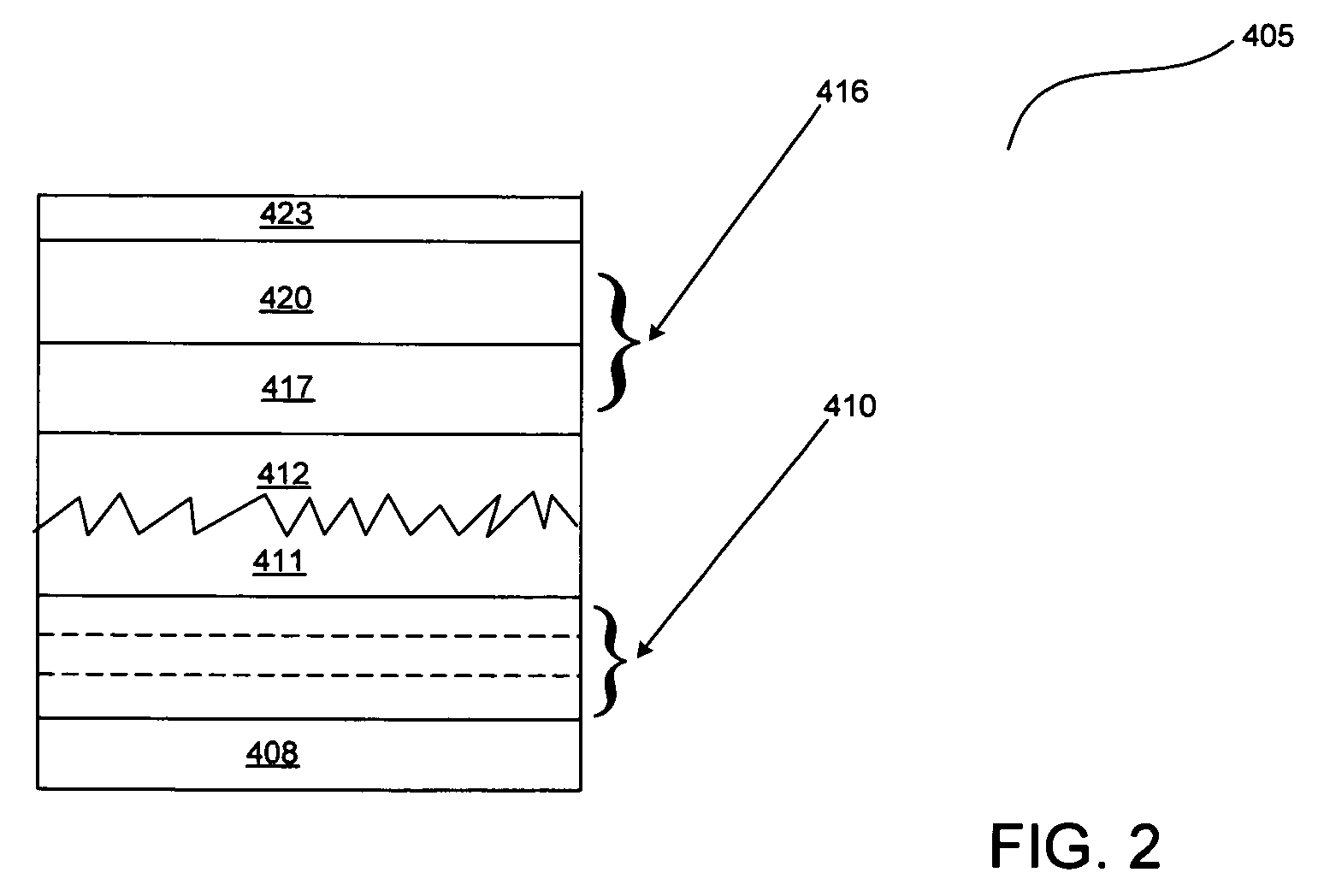

[0012] According to some embodiments of the invention, a DBR stack is utilized together with a surface modified anode layer to fabricate an OLED device. The surface modification creates lens like features on the top of the anode layer such that the angle of incidence of light from the emissive layer into the DBR stack is modified. Lens like features are defined as any feature that serves to focus / direct the light in the desired direction. It can be random or ordered, and may look like actual lenses. To maintain integrity of the organic layers of the OLED above the surface modified anode, a planarizing layer can also be provided between the surface modified anode layer and the organic layers so that a more uniform deposition surface is available for the organic layers. The surface modification of the anode layer can be accomplished by any appropriate patterning or deposition techniques such as wet-etching, lithography, e-beam lithography, stamping, or sputtering. The shape and patter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total thickness | aaaaa | aaaaa |

| work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com