Aluminum-based alloy composition and method of making extruded components from aluminum-based alloy compositions

a technology of aluminum alloy composition and composition, which is applied in the field of aluminum alloy composition and methods of making extruded components from aluminum alloy composition, can solve the problems of a relatively large number of small grain sizes after production, and achieve the effects of improving corrosion resistance, reducing die wear during die usage, and improving corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

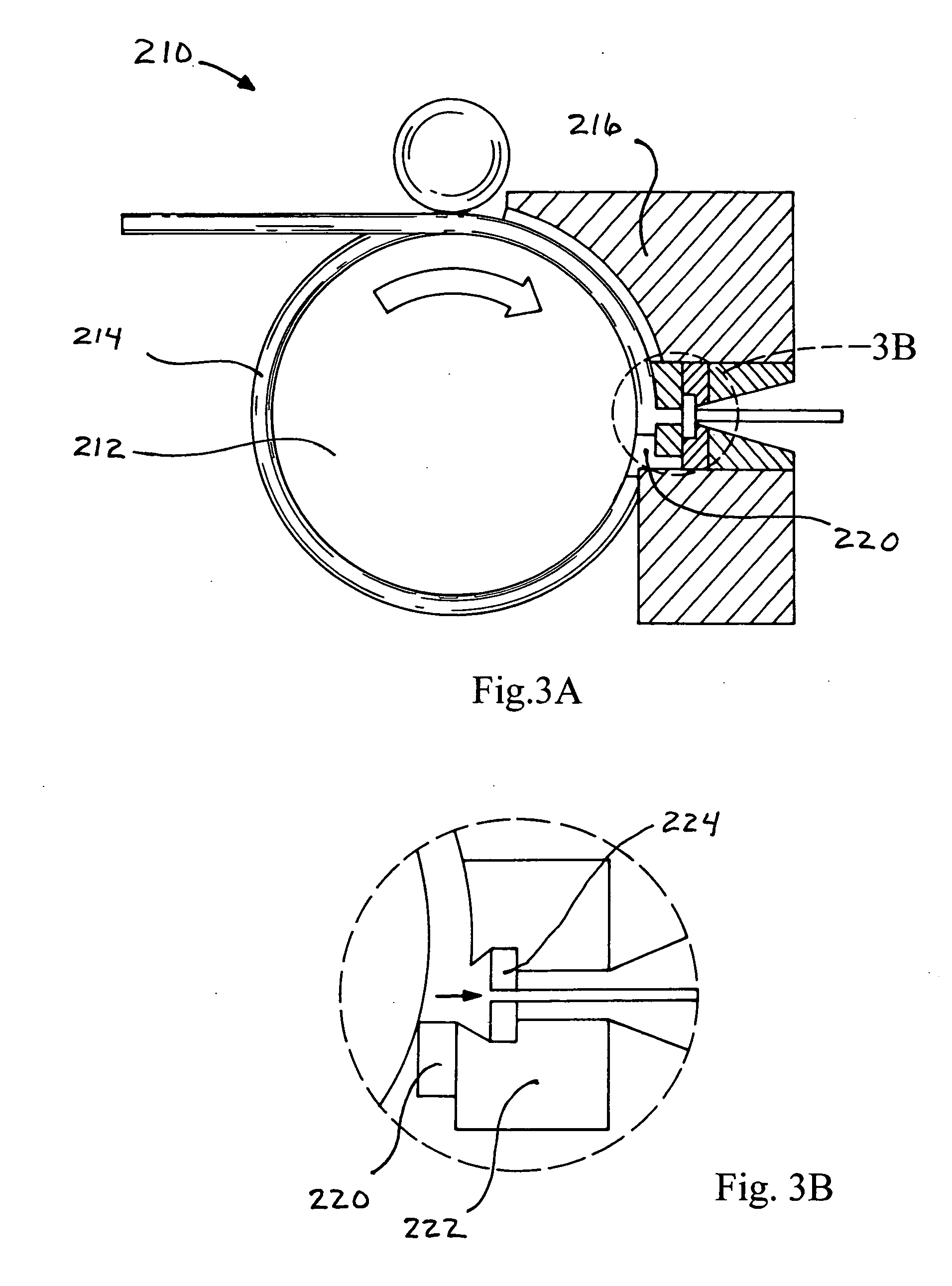

[0016] Embodiments of the present invention provide an aluminum-based alloy composition and methods of making components, e.g., vehicle heat exchanger tubes, from the aluminum-based alloy composition. The present invention provides a solution to concerns of apparatus size, efficiency, while maximizing in recrystallization and minimizing grain growth of the composition.

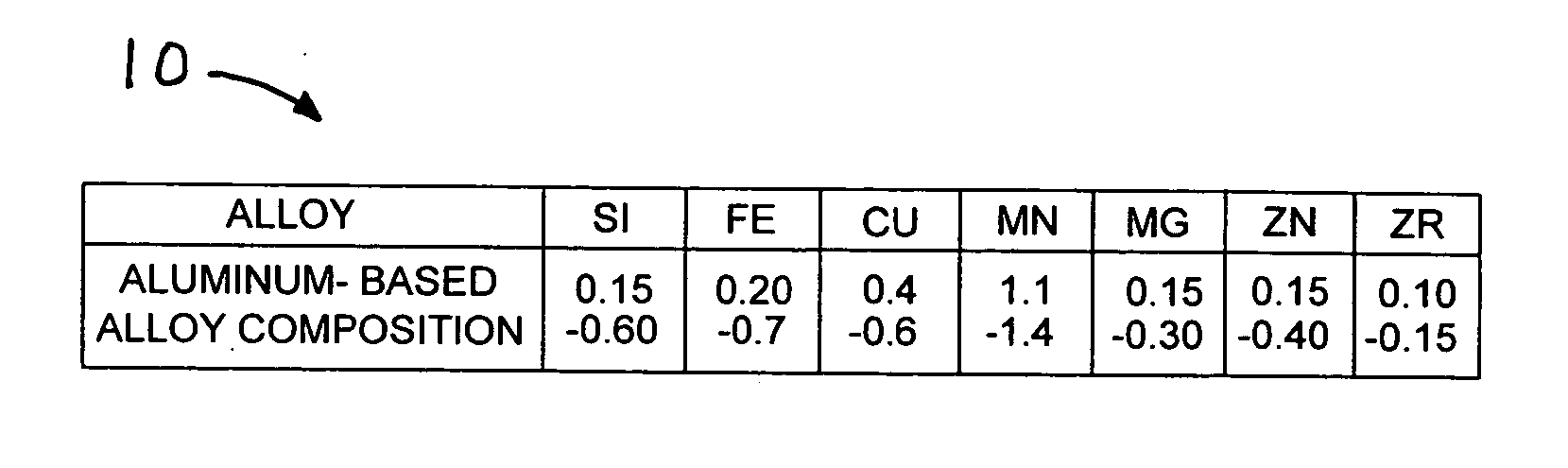

[0017] Generally, the composition includes added silicon for a reduced die wear, for enhanced die life, and for minimal grain growth. Recrystallization of the composition is further maximized with the use of copper, magnesium, and zinc. Grain growth of the composition is minimized by the use of zirconium, chromium, and manganese. Moreover, it is preferred that the silicon percent weight is relatively low, between about 0.15 and 0.30 to promote recrystallization. Additionally, it is to be understood that the composition is absent any titanium or chromium to minimize die wear.

[0018]FIG. 1 is a table 10 illustrating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com