Heat exchanger and method of manufacturing the same

a technology of heat exchanger and heat exchanger body, which is applied in the direction of manufacturing tools, soldering devices, light and heating equipment, etc., can solve the problems of fluid leakage from the heat exchanger, easy to occur joint defects, etc., and achieve the effect of enhancing the joint reliability of the tub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

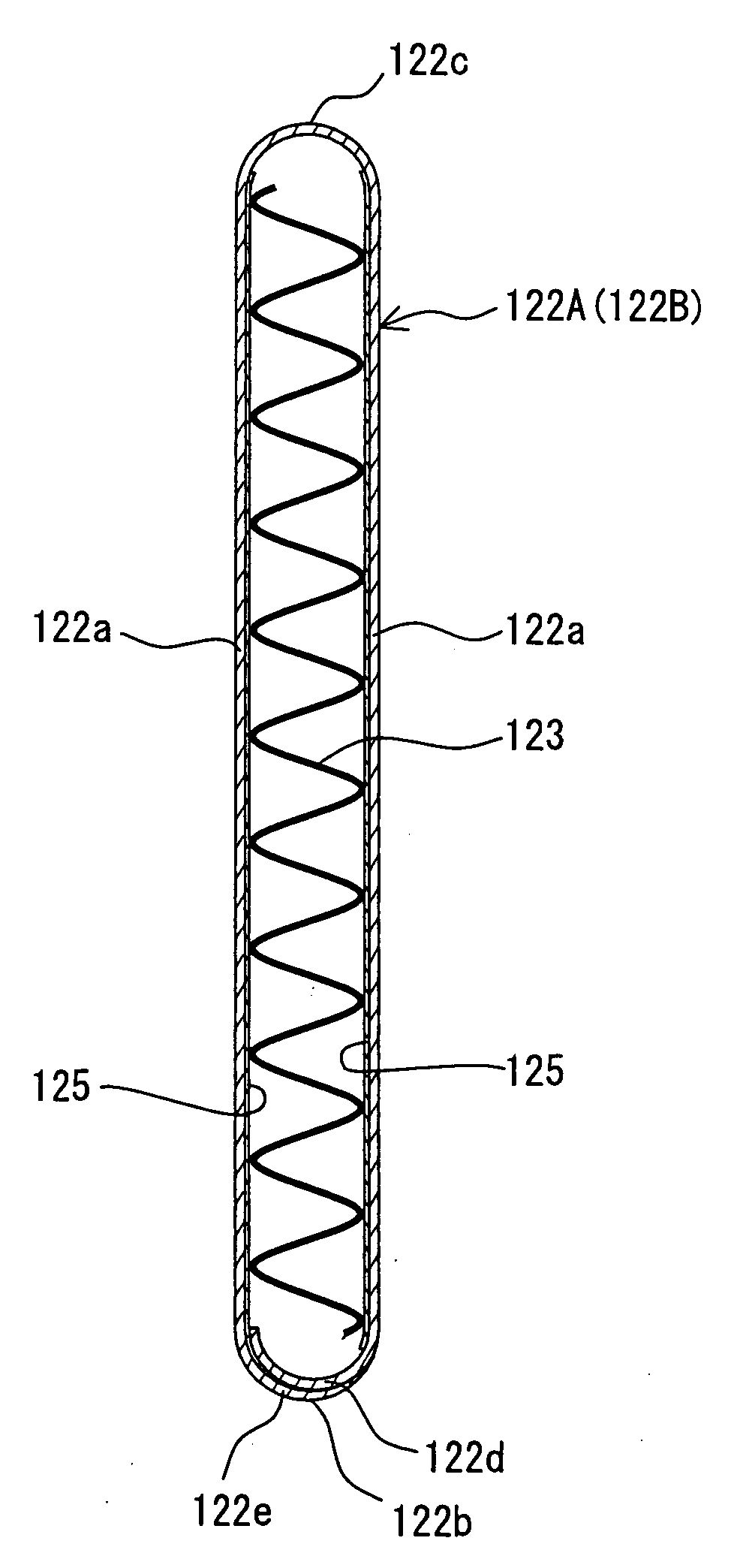

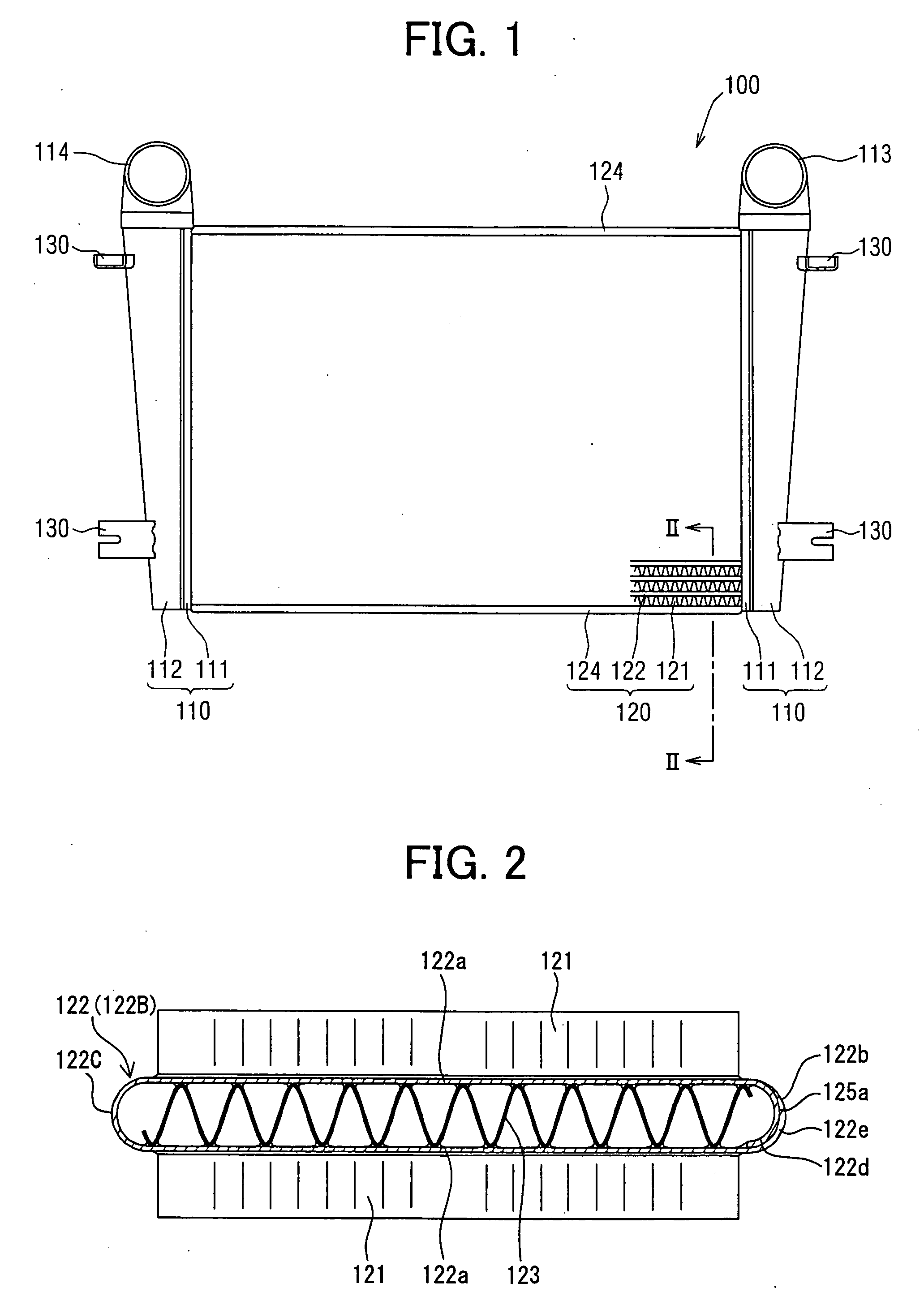

[0019] A first embodiment of the present invention will be described with reference to FIGS. 1-6. Referring to FIG. 1, a heat exchanger 100 (e.g., intercooler) is provided with a core member 120 and a pair of header tanks 110, which are respectively mounted at two ends (of longitudinal direction of tube 122 described later) of the core member 120. Each of the header tanks 110 has a hollow construction, and includes a core plate 111 and a tank portion 112 which are made of a copper alloy or the like and integrally joined by welding or brazing, for example.

[0020] One (e.g., at right side in FIG. 1) of the header tanks 110 is provided with an inlet joint 113 communicated with the interior of the one header tank 110. The other of the header tanks 110 (e.g., at left side in FIG. 1) is provided with an outlet joint 114 communicated with the interior of the other header tank 110. The inlet joint 113 can be connected with a discharge side of a supercharger (not shown), and the outlet joint...

second embodiment

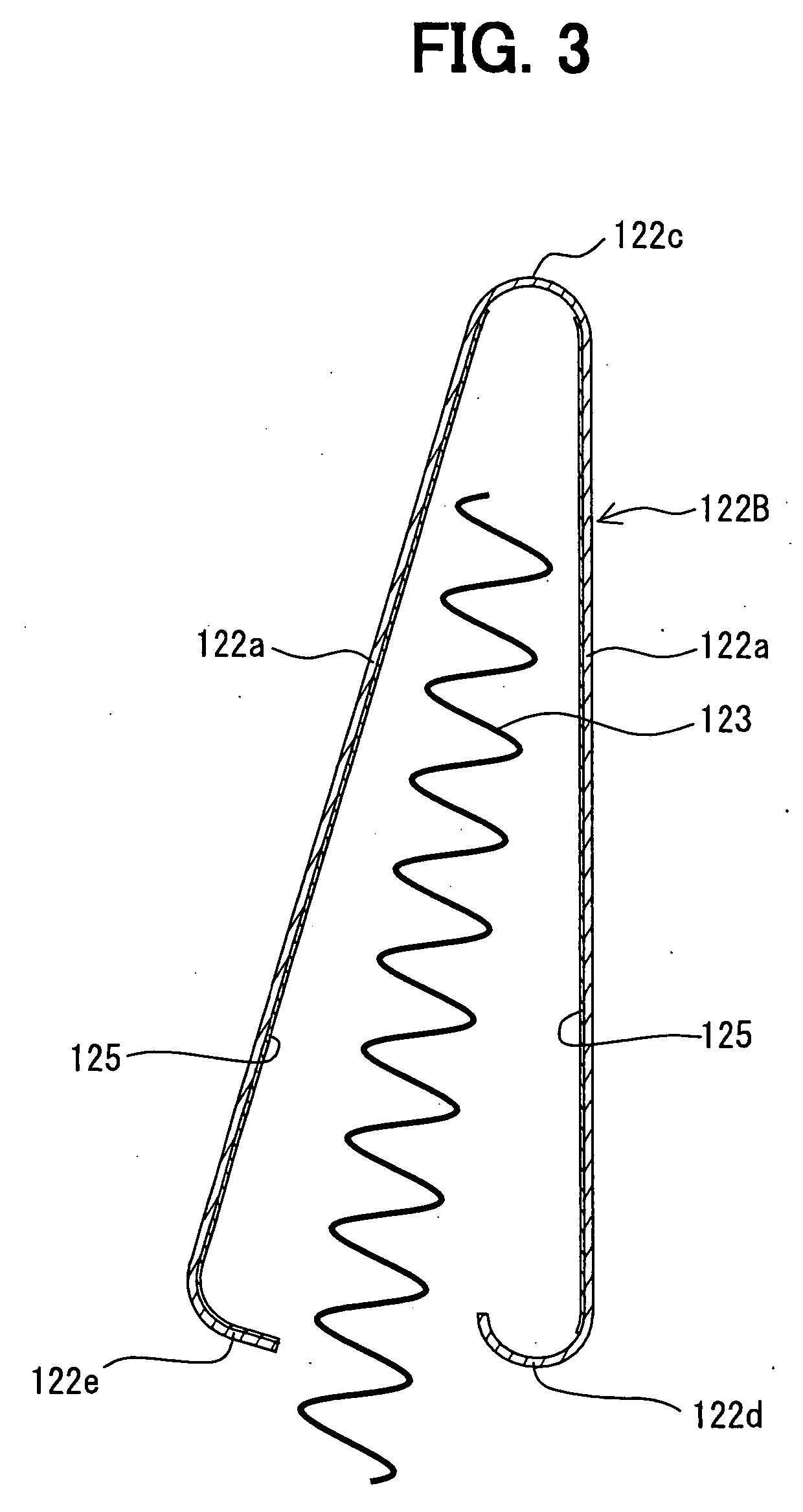

[0055] A second embodiment of the present invention will be described referring to FIGS. 7 and 8. In this case, a joint 225 at the bend portion 122b of the tube 122 is formed by welding.

[0056] In the second embodiment, the forming process of the tube body 122A is performed after the arranging process of the inner fin 123 is performed. That is the same with the above-described first embodiment.

[0057] Referring to FIG. 7, in the forming process of the tube body 122A, the second edge portion 122e is revolved toward the first edge portion 122d (i.e., toward right side in FIG. 7), so that the second edge portion 122e contacts the first edge portion 122e. Then, the first edge portion 122d is temporarily fixed to the second edge portion 122e to construct the arc-shaped bend portion 122b. In this case, a tip 122g of the second edge portion 122e is not prolonged (deformed).

[0058] Then, referring to FIG. 8, the joining process of the tube body 122A is performed. In this case, the tip 122g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com