Pattern cutter, its processing methods and moulds

a cutter and pattern technology, applied in the field of pattern cutters, can solve the problems of poor design consistency, low production efficiency, and unsuitability for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example 1

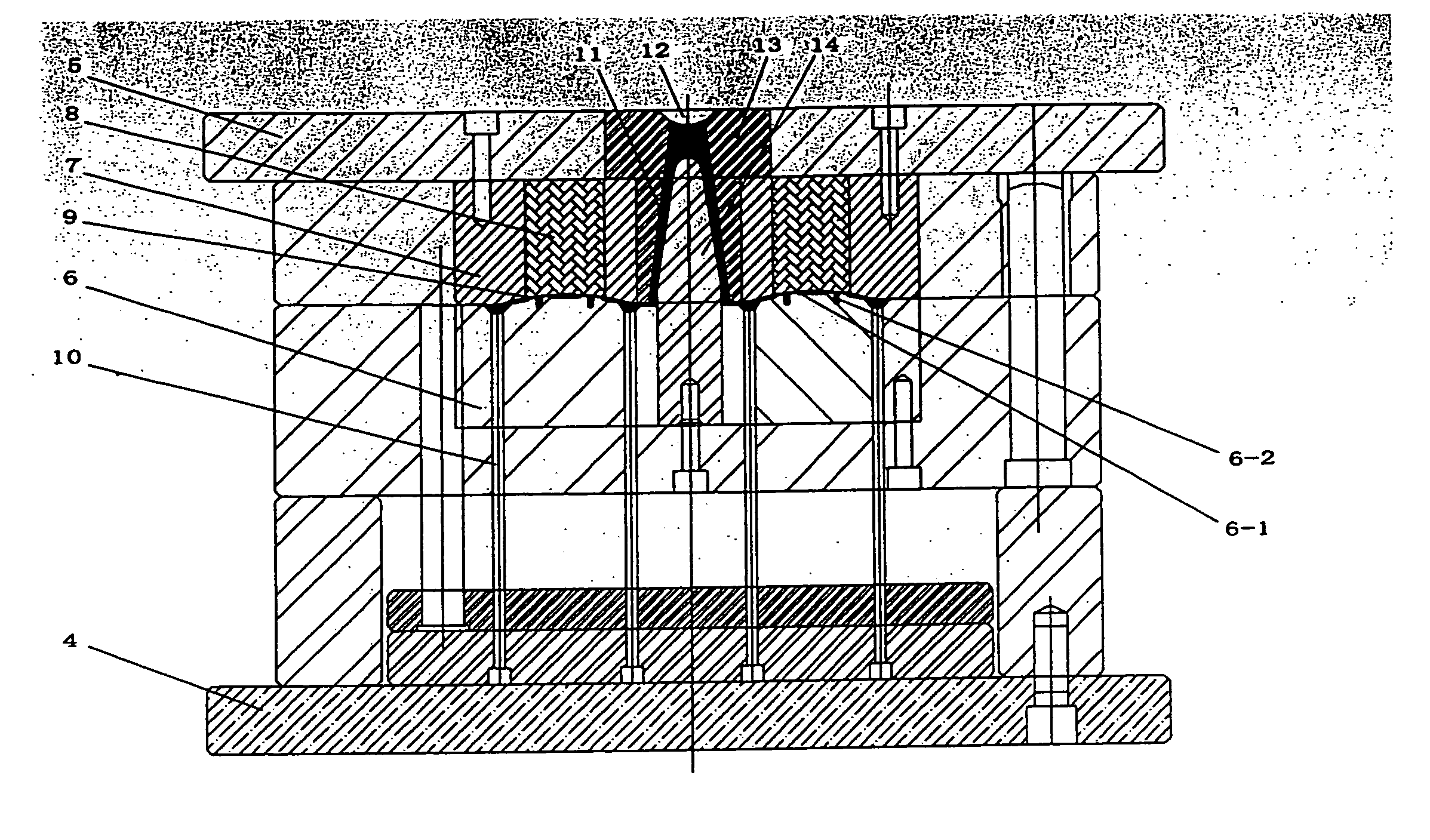

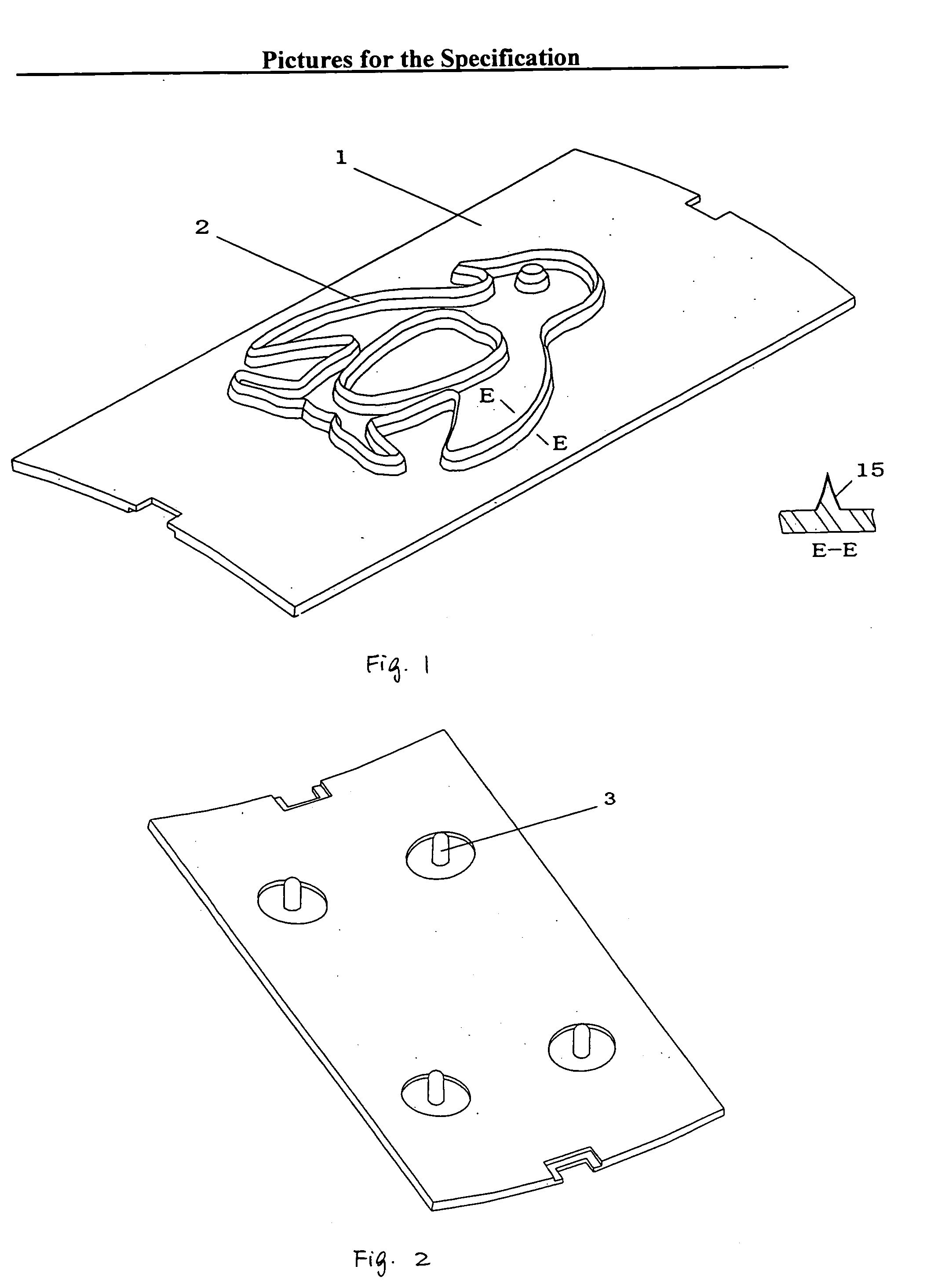

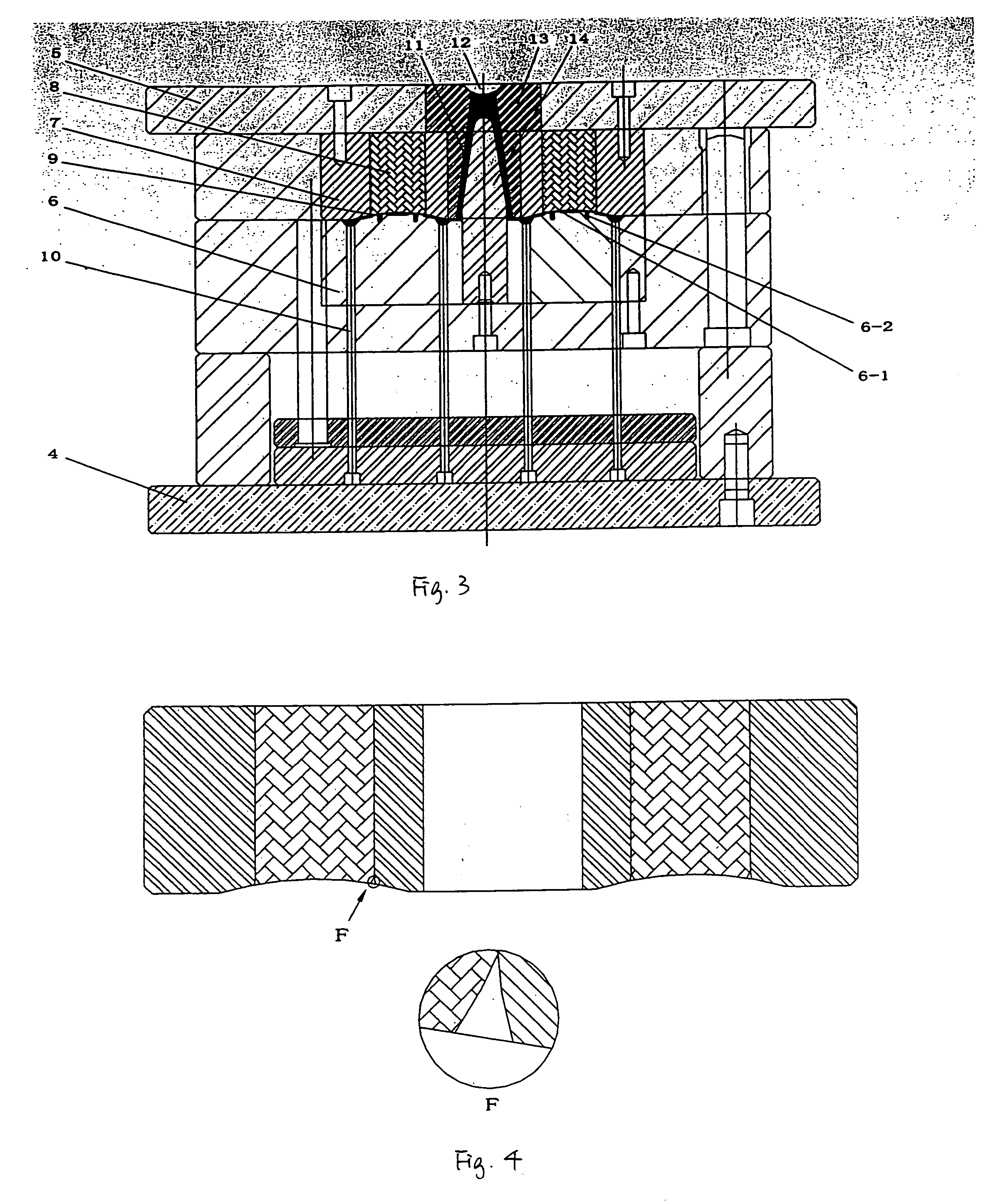

[0026]FIG. 1 and FIG. 2 show the concrete construction of the pattern cutter of the present invention. As shown in FIG. 1, the pattern cutter is composed of the base 1 and cutting blade 2. The base 1 is an arc plate with a certain radian. The cutting blade 2 is located on the base 1, with the surface of its cutting edge being in parallel to that of base 1 (both being of arc curved surface). The cutting blade 2 forms a penguin pattern shape to be cut. The said base 1 and cutting blade 2 are of one-piece construction. The specific cross sectional structure is shown in E-E view of FIG. 1. The cutting blade 2 has a cross sectional shape similar to triangle (the exact shape is the combination of triangle and trapezoid). The height of cutting blade 2 is 3 mm on the base 1. The cutting blade 2 has an angle of 30° at the cutting edge. On the surface of cutting blade 2 there is a plating coat 15. The holding legs 3 are integrally made on the said base 1 at the other side opposite to the surf...

working example 2

[0028]FIG. 6 shows another construction of the pattern cutter as set forth in the present invention. As shown in FIG. 6, this pattern cutter comprises a base 1 and cutting blade 2. The base 1 is a flat plate, with the cutting blade 2 located on the base 1. The surface for the cutting edge of the blade is in parallel to that of the base 1 (both of them being of plane). The cutting blade 2 forms the circular pattern shape that is to be cut. The said base 1 and the cutting blade 2 are of one-piece structure. The specific cross sectional structure is as shown in G-G view of FIG. 6. The cross sectional shape of the cutting blade 2 is of triangle. The height of the cutting blade 2 is 4 mm on the base 1. The blade 2 has an angle of 40° at the cutting edge. The cutting blade 2 is surfaced with a chromium-plating coat 15.

[0029] The methods for manufacturing the pattern cutter as set forth in the present working example are the same as those in the working example 1 in addition to the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| included angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com