Cigarette lighter with improved safety properties

a safety property and lighter technology, applied in the field of cigarette lighters, can solve the problems of small flames, such as those found in cigarette/utility lighters, incipient fires, and significant fire hazards, and achieve the effect of improving safety properties and improving ignition propensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

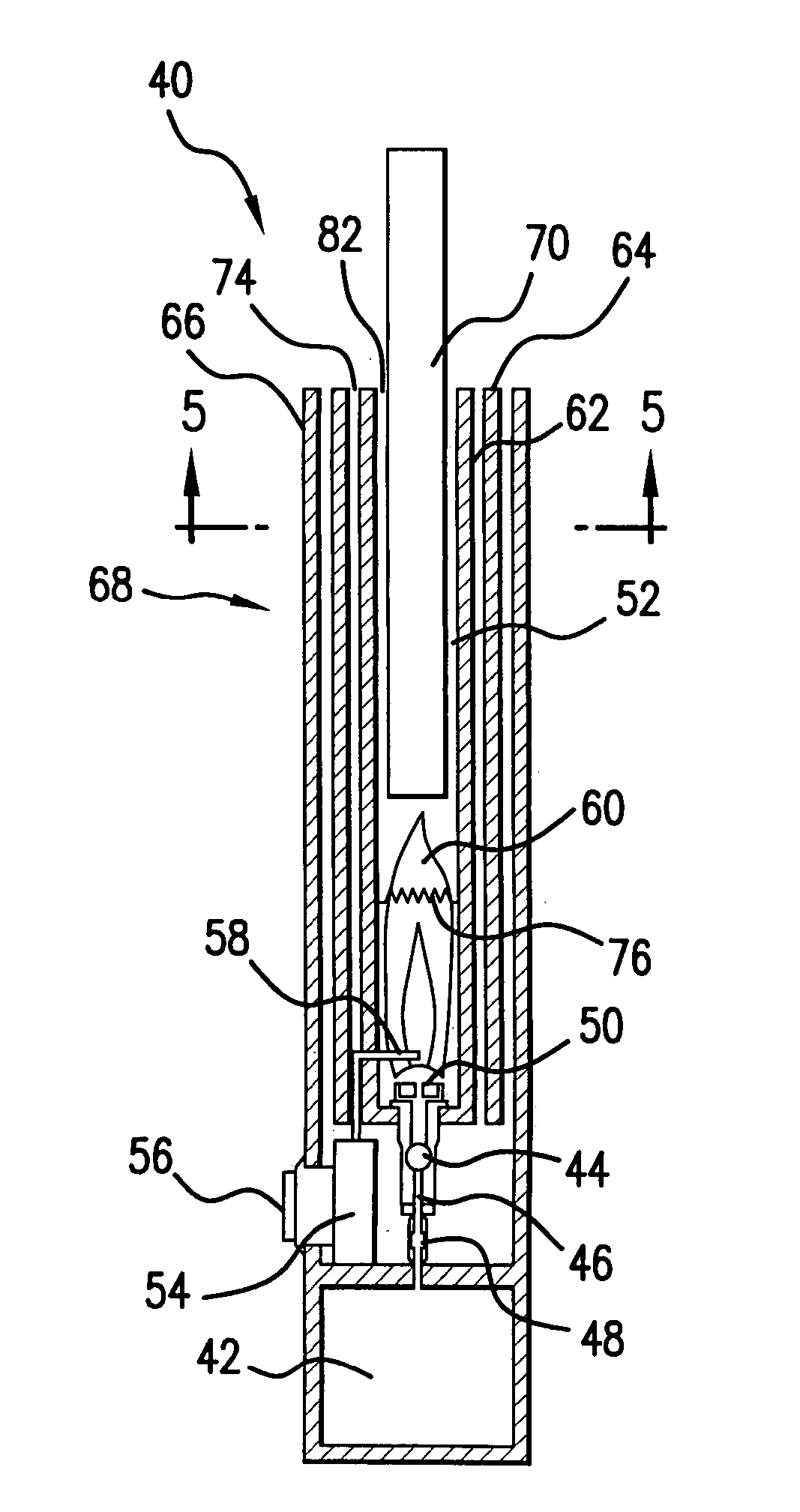

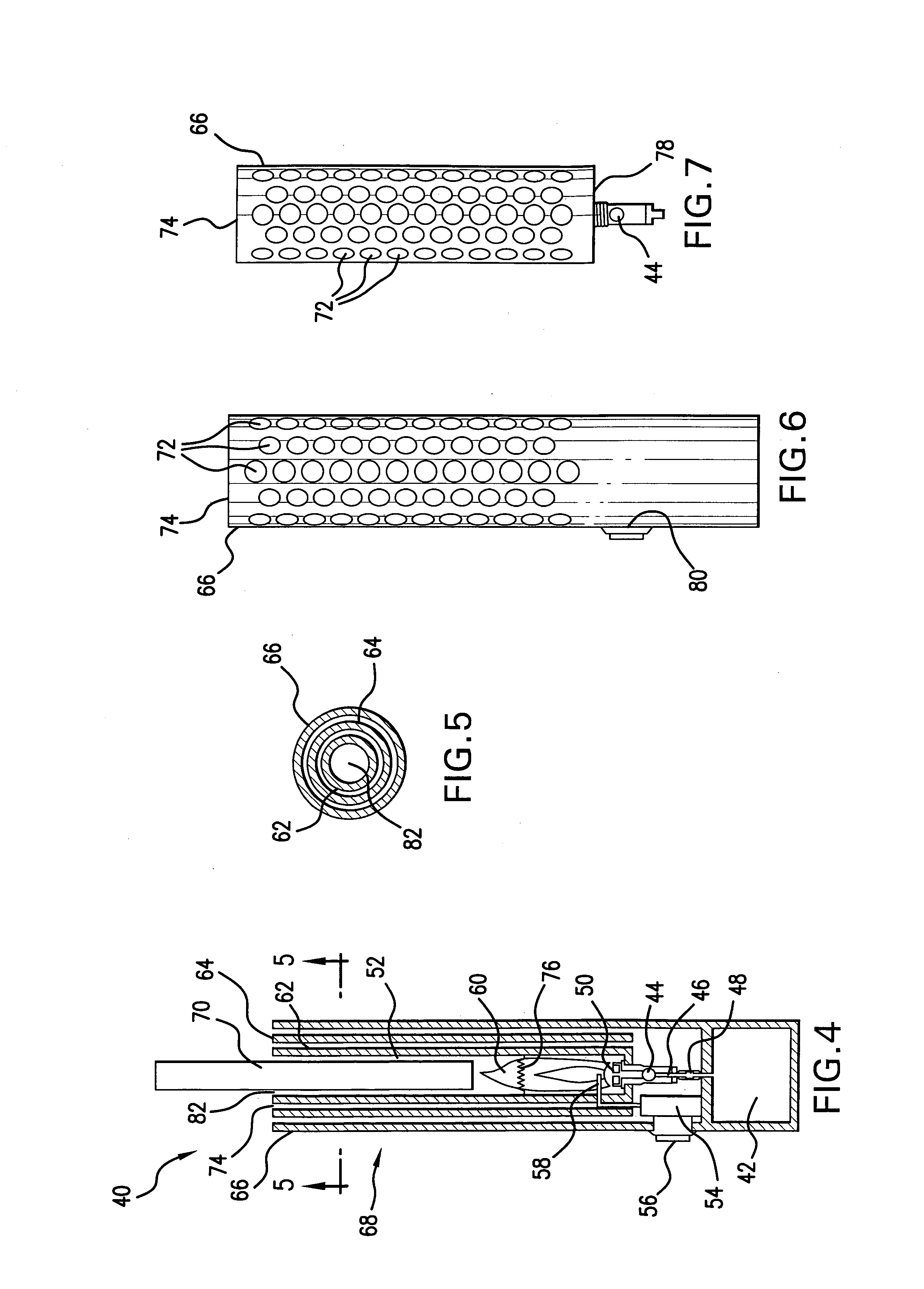

[0048] Referring to FIG. 4, cigarette lighter 40 of the present invention includes a fuel reservoir 42 containing fuel. The fuel is delivered to an air mixing chamber 44 through the orifice 46. The fuel reservoir 42 is connected to the orifice 46 by a fuel connection tube 48. In the air mixing chamber 44, the fuel mixes with the air to form the air-fuel mixture which is delivered to a burner nozzle 50 and is injected therethrough into a combustion chamber 52.

[0049] A piezoelectric spark device 54 is operatively coupled to an operation button 56 for actuation / deactuation. Upon actuation, the piezoelectric spark device 54 generates a discharge which is delivered through a spark ignition wire 58 into the combustion chamber 52 filled with the fuel-air mixture. The discharge from the spark ignition wire 58 ignites the fuel-air mixture in the combustion chamber and produces a flame 60 therein.

[0050] The combustion chamber 52 consists of three concentric vented stainless steel tubes 62, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com