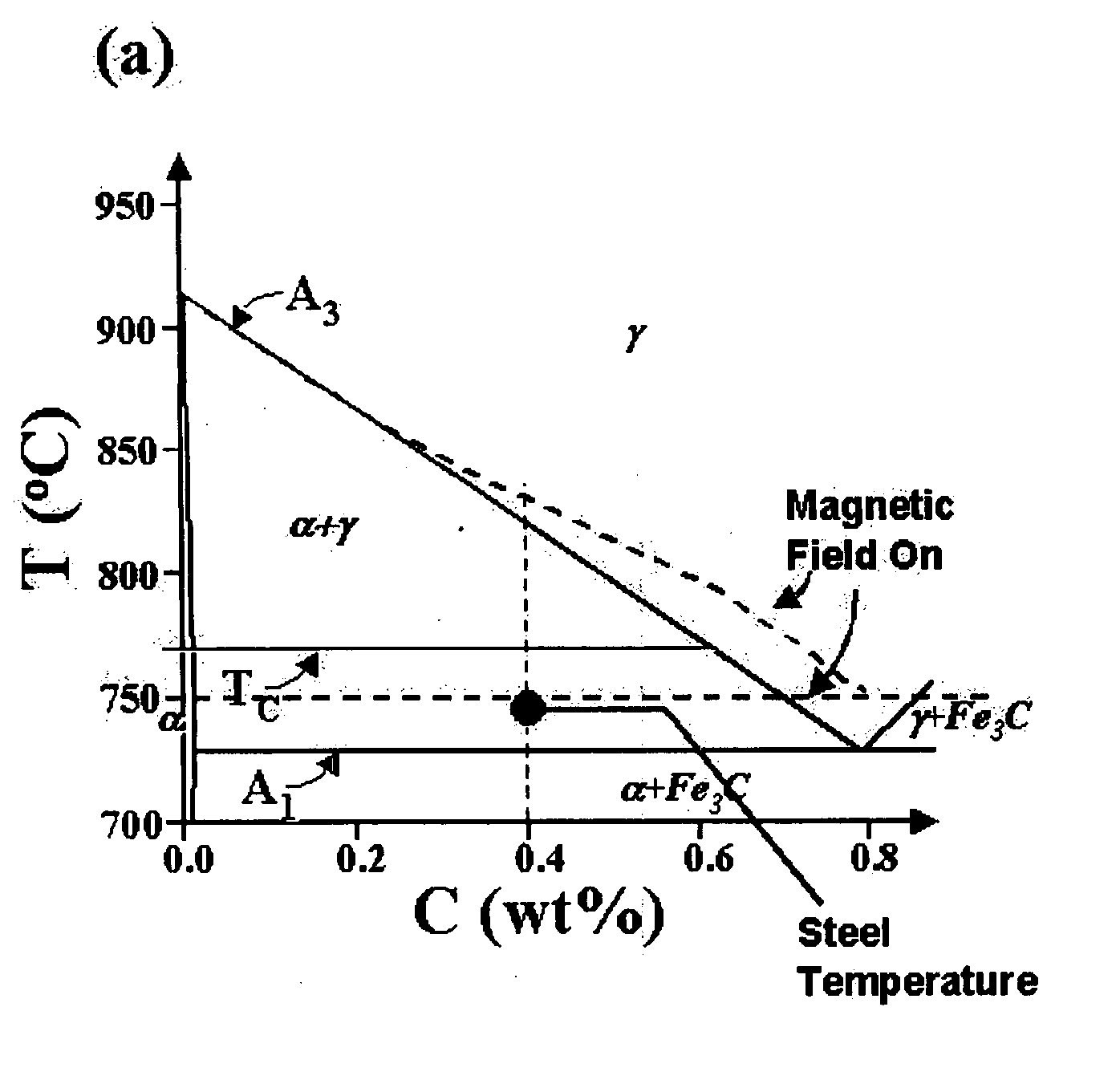

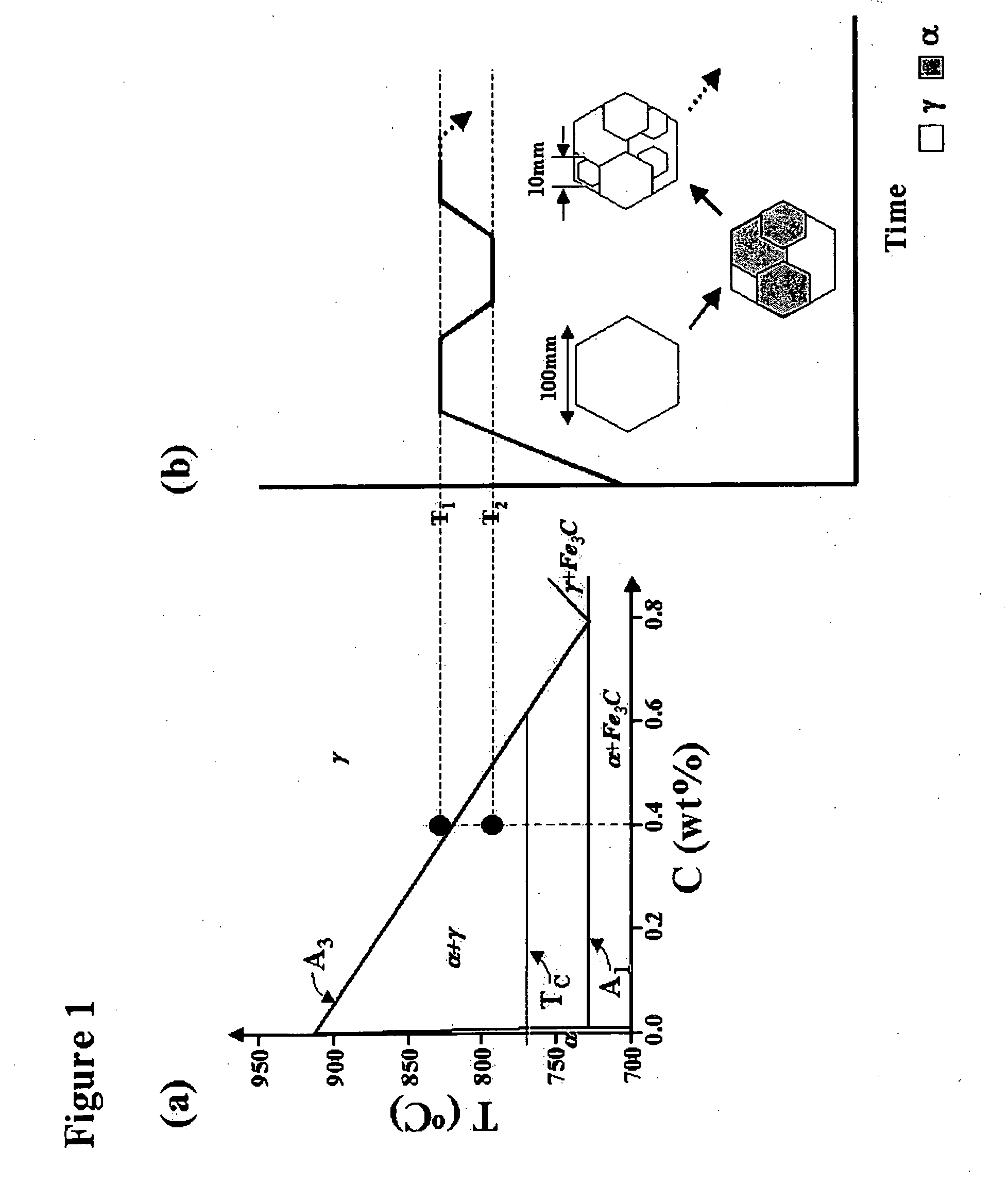

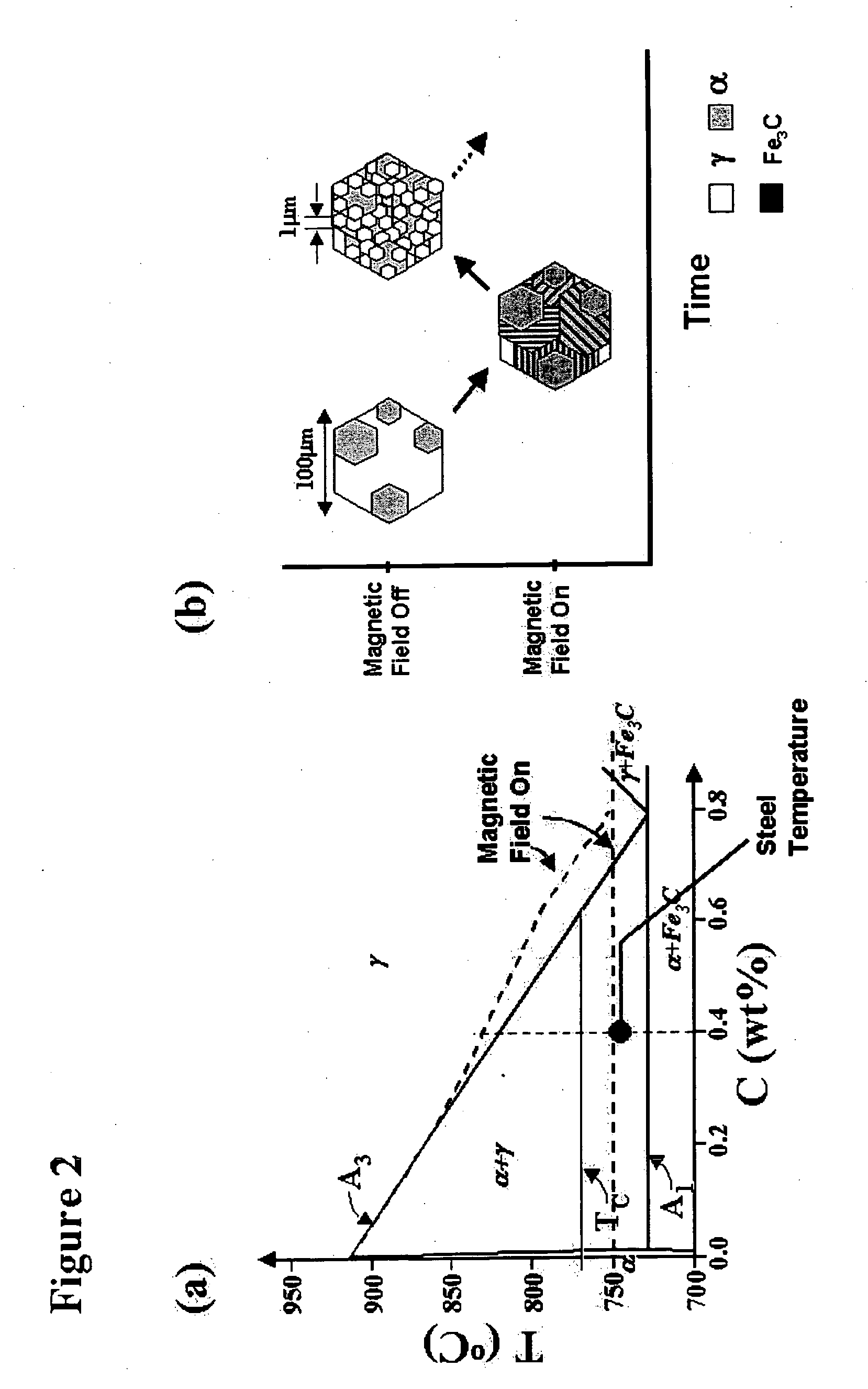

[0016] The invention includes a method for refining the grain size by applying a magnetic field in alloys to reversibly induce phase transitions between ferromagnetic and paramagnetic phases. Other magnetic phases are envisioned but less preferred. This phase transformation can be induced by changes in application of a magnetic field with or without a change in temperature. This invention is based on the effect of a magnetic field fundamentally lowering the

free energies and enhancing the thermodynamic stability of the ferromagnetic phase(s), resulting in shifting of the phase boundaries. For this invention the two phases (e.g., ferromagnetic and paramagnetic phases) have different chemistries and / or preferably different crystalline structures and transition from one phase to the other phase requires a

chemistry (e.g., precipitates) and / or crystalline structure change. The magnetic field is applied and ceased or decreased for one or more cycles to obtain the desired equiaxed grain size. The number of cycles is preferably less than 100, more preferably less than 10, even more preferably less than 5. The time between cycles is preferably about the same as the time the magnetic field is applied, but can be up to 10 times shorter or greater. Ramping time during increasing or decreasing the magnetic field is preferably minimized. Ramp up and ramp down times for 5%←→95% of the peak magnetic field are preferably less than 10 seconds, more preferably less than 5 seconds, and even more preferably less than 1 second. The magnetic field can be stepped up and / or down (preferably in one step) or ramped up and / or down. For example as seen in FIG. 4, the magnetic field can be increased and / or decreased in either a single or multiple steps. The

phase boundary temperature is shifted up (with increasing magnetic field) or reverted (with decreasing magnetic field) so that the equilibrium ratio of different phases changes. Ratios can be measured by volume ratios, wherein a

single phase has a ration of, for example, 100%:0%. Hence, the invention is directed to a method for refining the equiaxed grain size of an alloy which undergoes a ferromagnetic to paramagnetic transition comprising (a) subjecting said alloy to a magnetic field of a sufficient strength and for a time sufficient to cause said alloy to transition from its original

initial phase ratio (condition A) to a new

phase ratio (condition B), and (b) decreasing said magnetic field to allow said alloy to transition to yet a different

phase ratio (condition C), wherein said condition C may be the same or different from said condition A, and optionally repeating steps (a) and (b). The decreasing of magnetic field in (b) may include reducing the magnetic field to zero as well as changing it to a strength different from that in (a).

[0017] The invention produces a

metal or alloy, at the high temperature chosen for magnetic

processing, having fine equiaxed grain size of less than 10 micrometers, preferably less than about 5 micrometers, and even more preferably less than about 1 micron. In a preferred embodiment, the alloy is cooled (e.g.,

ambient air cooling, fast

quenching in a fluid medium, accelerated cooling in a medium) after magnetic

processing to below about 500-550° C. to minimize

grain growth. In another embodiment, said fine equiaxed grain

metal or alloy can be subjected to subsequent

processing by conventional methods to further reduce the grain size. Said conventional processing includes high temperature processing (e.g., thermo-mechanical controlled processing—TMCP, hot rolling, hot bending, hot

forging, etc.) and cooling from high temperature to ambient or some temperature in between. In addition to grain size and shape, the materials produced by this invention can have improved

grain distribution, and surfaces.

Login to View More

Login to View More