Loofah washcloth with varied areas of coarseness and method

a technology of coarseness and washcloth, applied in the field of washcloths, can solve the problems of unadulterated and manufactured loofah washcloth, and achieve the effect of simple and inexpensive process and maximum use of loofah

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

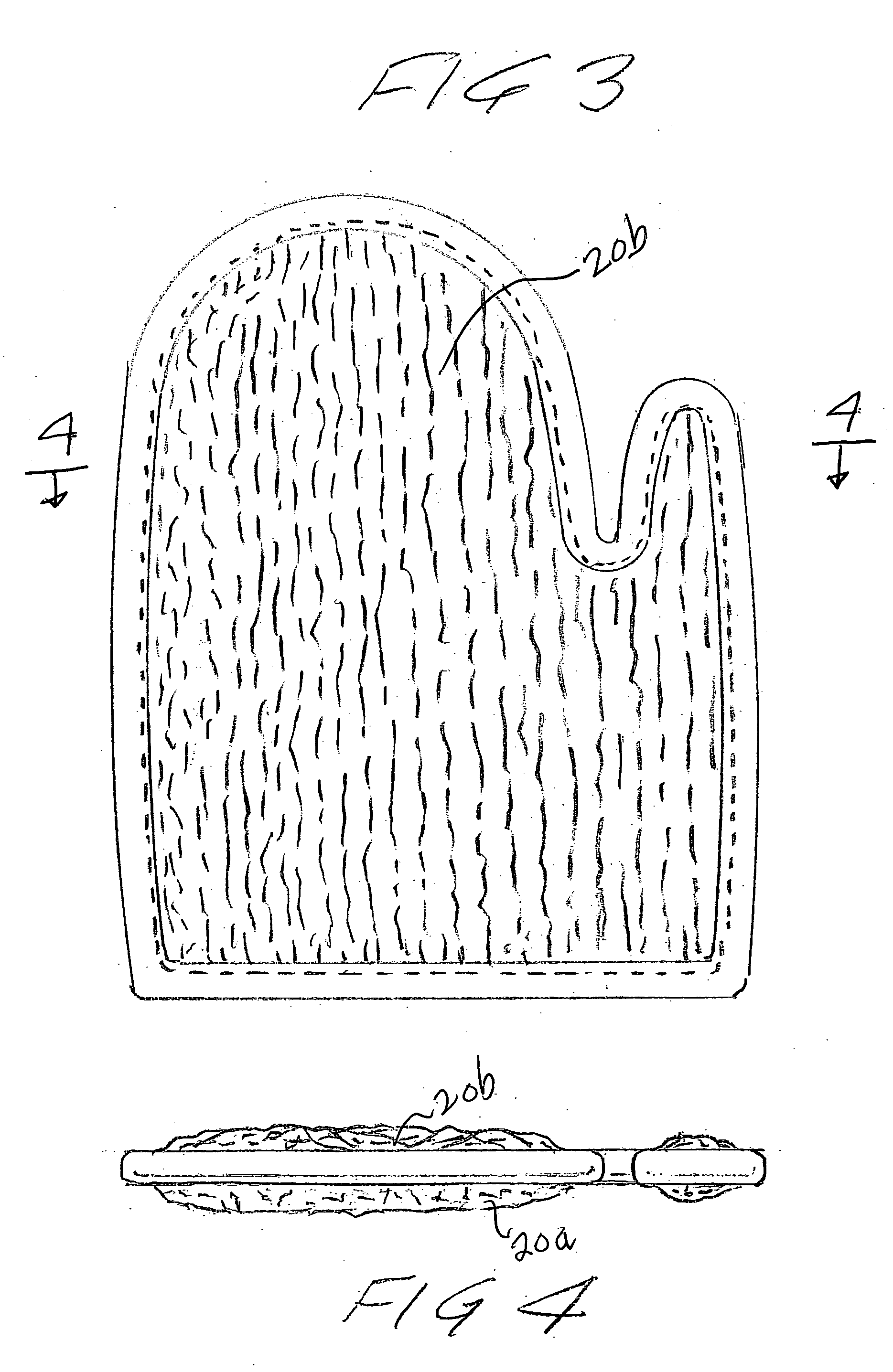

[0028] In order to better understand the present invention in conjunction with the drawings of FIGS. 1-5, the overall washcloth of the present invention has been assigned reference numeral 10 and its elements are described and assigned the reference numerals identified below.

[0029] As best seen in FIGS. 1-4, washcloth 10 is comprised of a two-sided sheet 20 of a fibrous scrubbing material, such as loofah, together with a cloth border 40 stitched to loofah sheet 20. Loofah sheet 20 has usable substantially planar upper surface 20a and usable substantially planar lower surface 20b. Reinforcing outer border 40 typically made of cloth is located around the outer perimeter of the washcloth and is for reinforcement and for maintaining smoothness. The border 40 forms the edge of the washcloth so it spans the thickness of sheet 20 from upper surface 20a to lower surface 20b of sheet 20. The present invention also contemplates eliminating cloth outer border 40 or replacing it with other sui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com