Hollow fiber membrane contact apparatus and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

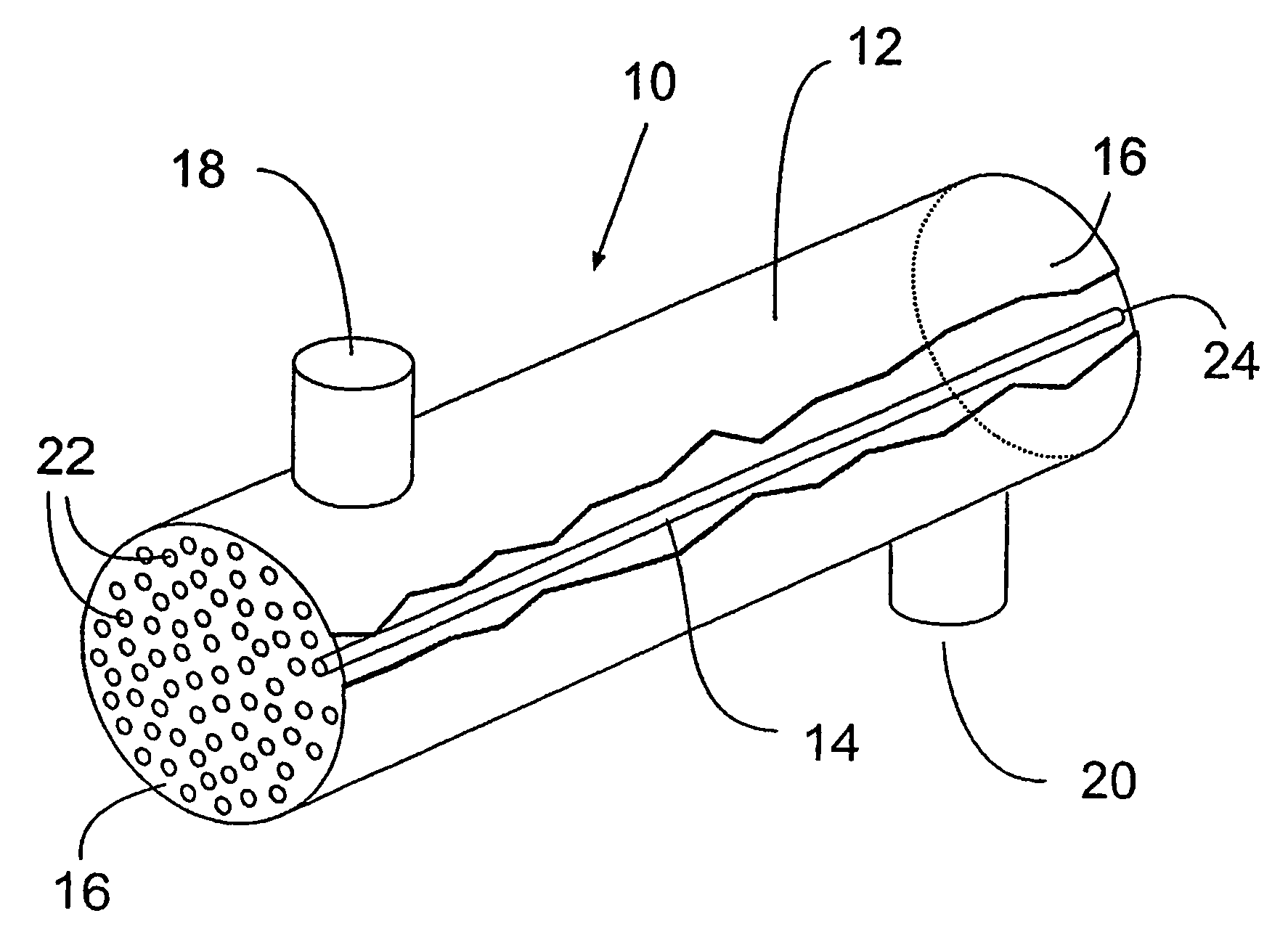

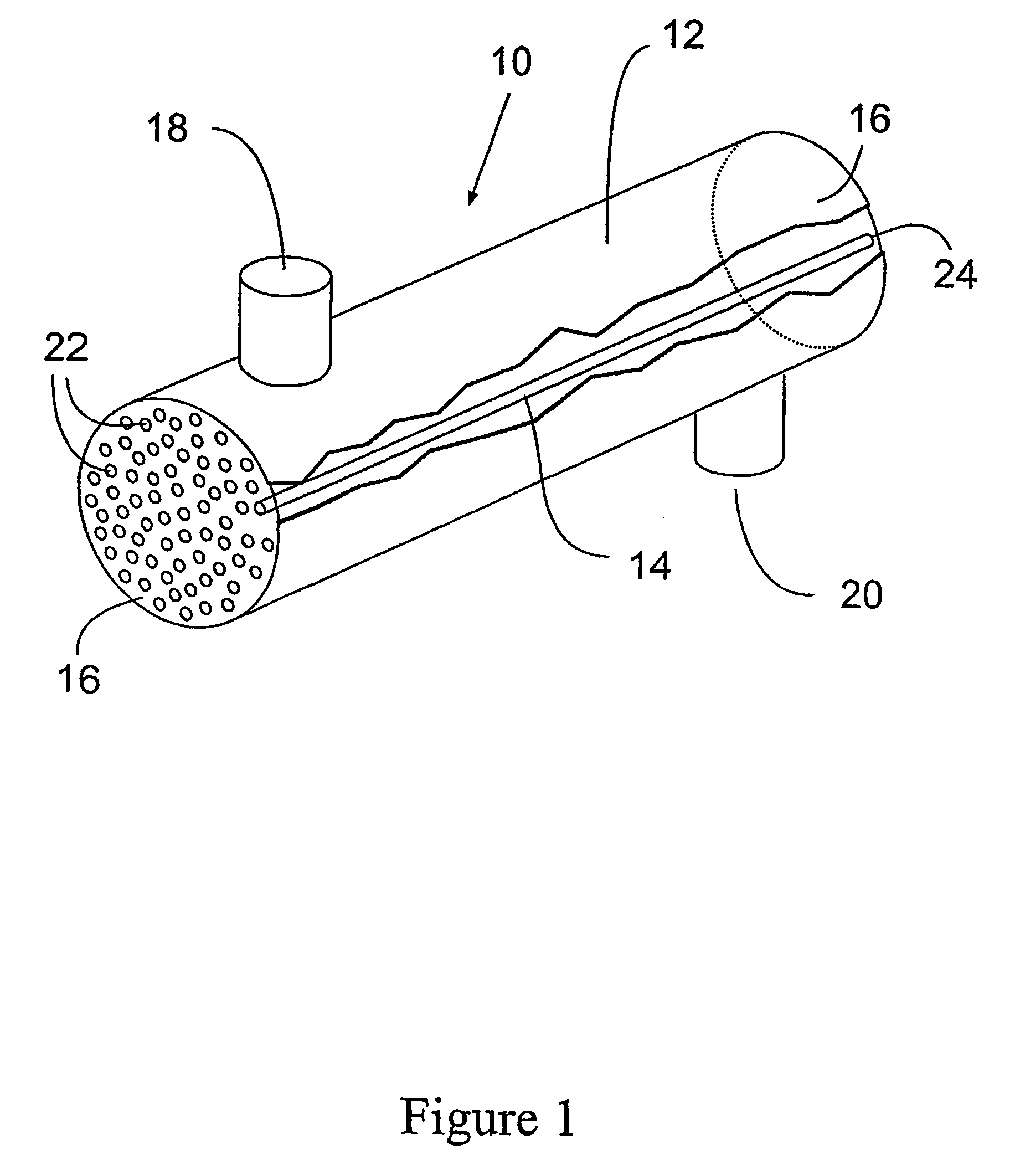

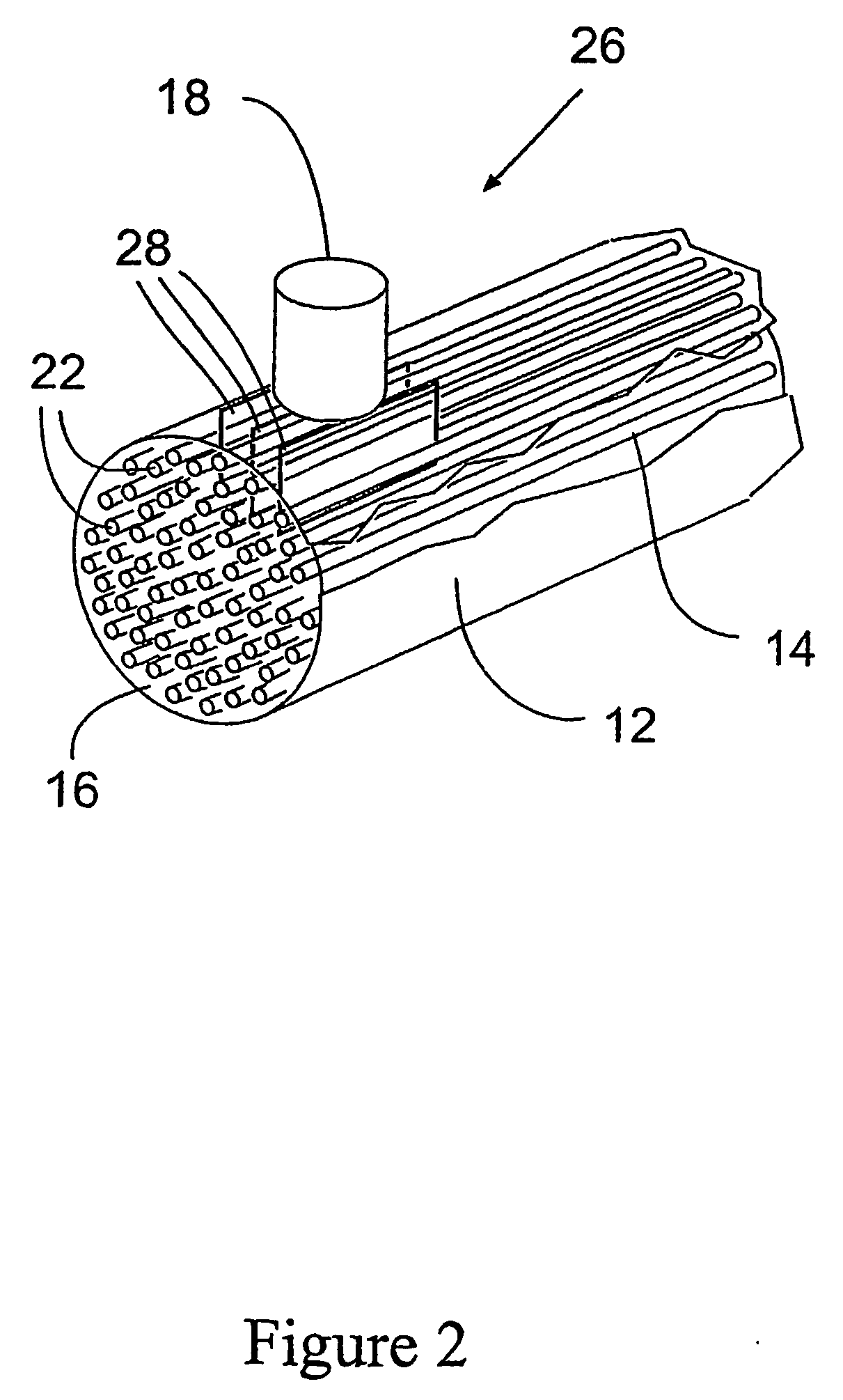

Image

Examples

example 1

[0082] A contactor with dimensions of 2.25″ ID and 12″ in length was made using porous skinless PFA hollow fibers. The fiber outer diameter (OD) was about 800 microns and the inner diameter (ID) about 500 microns. The number of the fibers was about 2100 and the packing density was around 0.46 m2 of external membrane area / liter of internal cartridge volume. The fiber bundle was potted with an offset of ¼″ gas fitting at both end of the module. Two 1″ fittings for water flow were bonded on the shell at cross-direction near the exit and entrance. The inside of the fitting was reduced to ½″ using an insert to create jetting action of water into the bundle. The water fittings are located perpendicular to the offset of the potting such that a cavity is formed right under the fitting.

[0083] The contactor was tested for ozonation efficiency. Ozone gas at 22 psig., 250 gNm3 and 5 slpm was fed into the gas port of the contactor. Deionized (DI) water was pumped into the contactor using the sh...

example 2

[0084] A contactor with dimensions of 2″ ID and 15″ in length was made using porous skinless PFA hollow fibers. The fiber OD was about 800 micron and the ID about 500 micron. The number of the fibers was about 1700 and the packing density was around 0.42 m2 membrane / liter of internal cartridge volume. The contactor was fitted with ¼″ gas fitting at both end of the module. Two ½″ fitting for water flow were bonded on the shell at cross direction near the exit and entrance.

[0085] The contactor was tested for ozonation efficiency. Ozone gas at 22 psig. 250 g / Nm3 and 5 slpm was fed into the gas port of the contactor. DI water was pumped into the contactor using the shell-side water fitting at a rate of 5 gpm at 25C. The pressure drop was less than 5 psig. The concentration of ozone in the outlet water was measured using an IN-USA ozone sensor. After a couple of minutes, the ozone concentration in the water reached 26 ppm. Under the same operating conditions, the same contactor would pr...

example 3

[0086] A contactor with dimensions of 2.25″ ID and 12″ in length was made using porous skinless PFA hollow fibers. The fiber outer diameter (OD) was about 700 microns and the inner diameter (ID) about 400 microns. The number of the fibers was about 4000 and the packing density was around 0.86 m2 of external membrane area / liter of internal cartridge volume. The fiber bundle was potted with an offset of ¼″ gas fitting at both end of the module. Two 1″ fittings for water flow were bonded on the shell at cross-direction near the exit and entrance. The inside of the fitting was reduced to ½″ using an insert to create jetting action of water into the bundle. The water fittings are located perpendicular to the offset of the potting such that a cavity is formed right under the fitting.

[0087] The contactor was tested for ozonation efficiency. Ozone gas at 22 psig., 250 gNm3 and 5 slpm was fed into the gas port of the contactor. Deionized (DI) water was pumped into the contactor using the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com