Apparatus and method for controlling the amount of trash in lint

a technology of lint cleaning and trash removal, applied in the direction of mechanical treatment, mechanical fibre separation, textiles and paper, etc., can solve the problems of loss of lint to the producer, inability of existing lint cleaning machines to provide a method to vary the amount of cleaning the machine performs, and damage to the fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

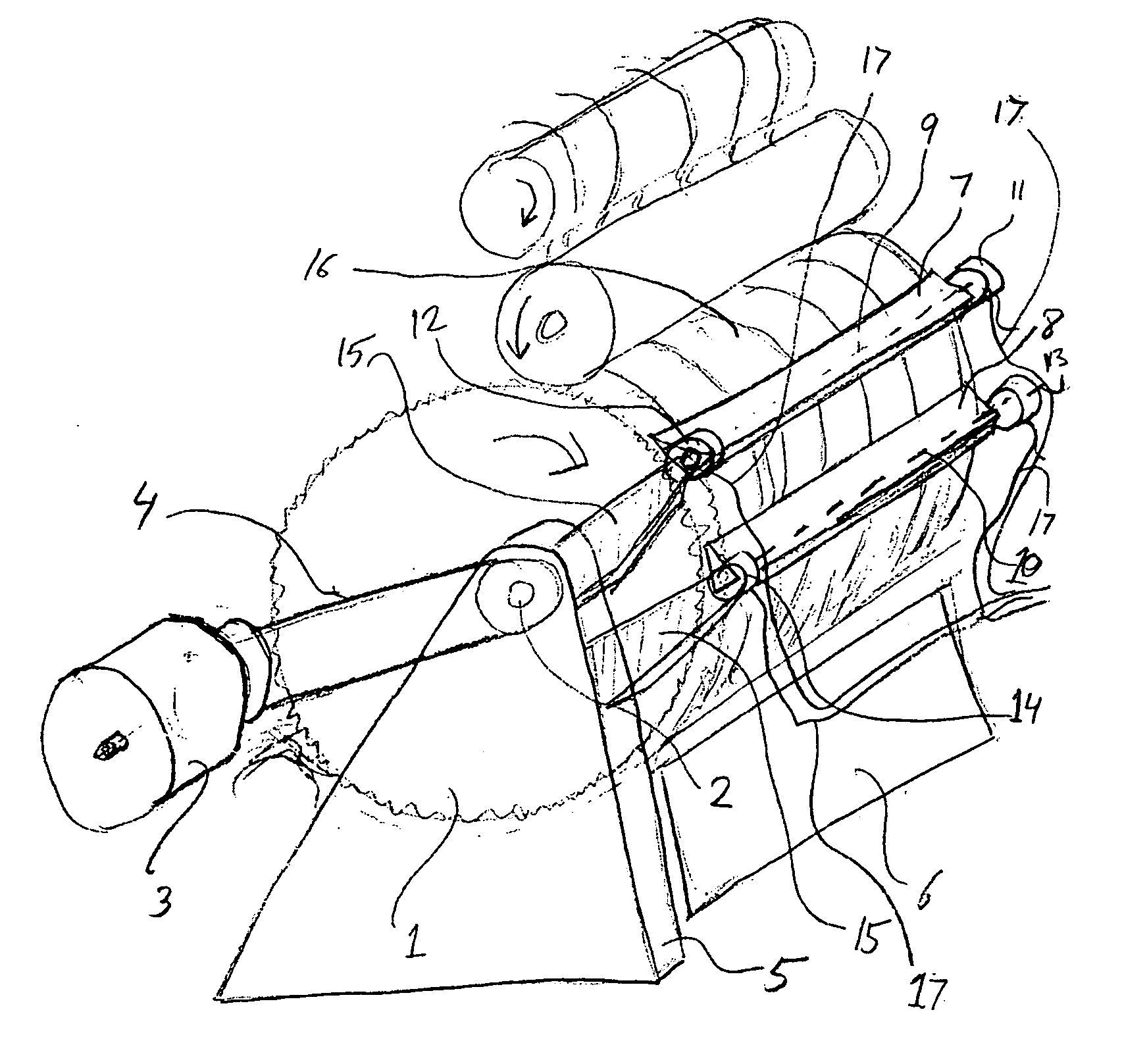

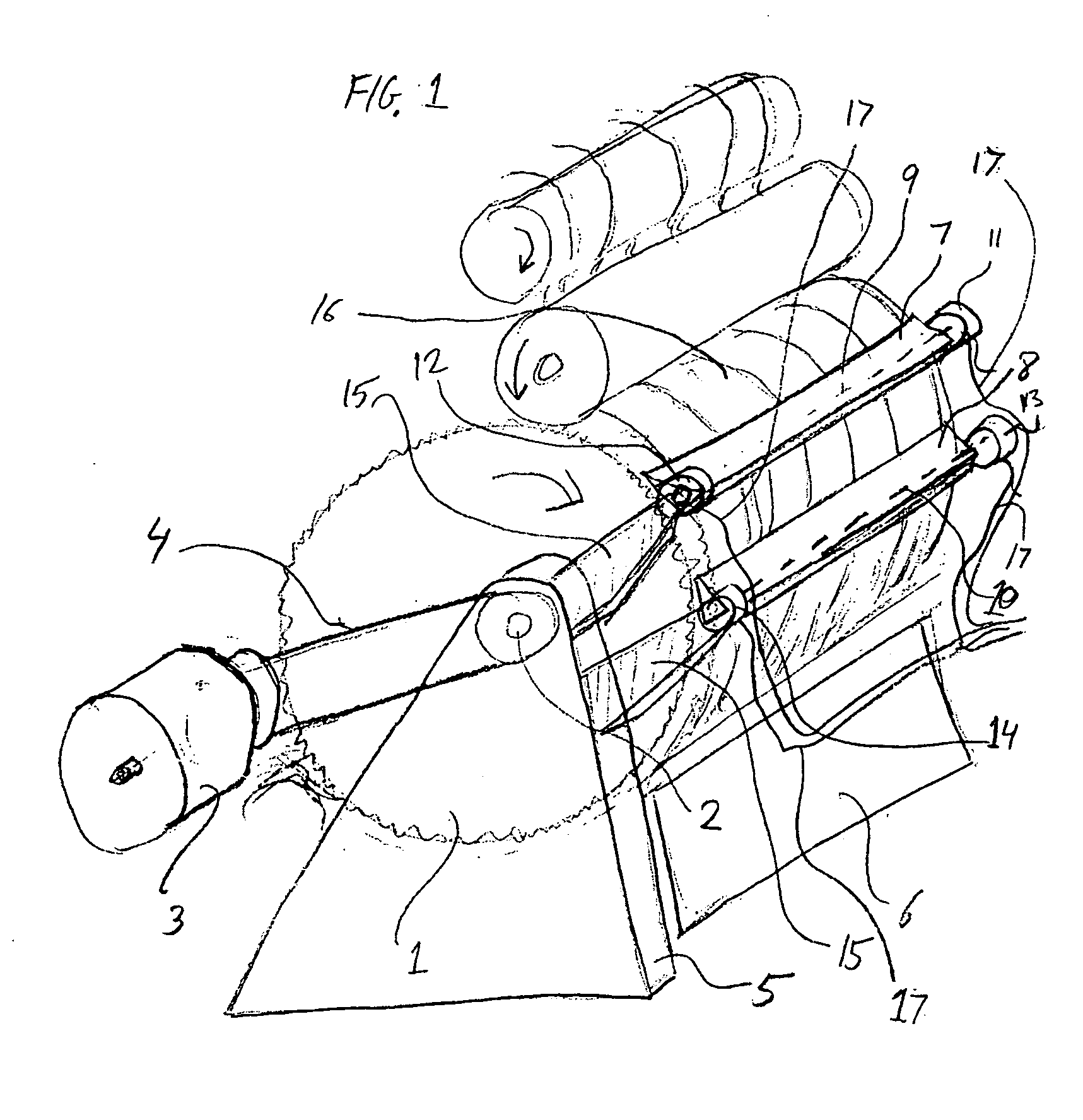

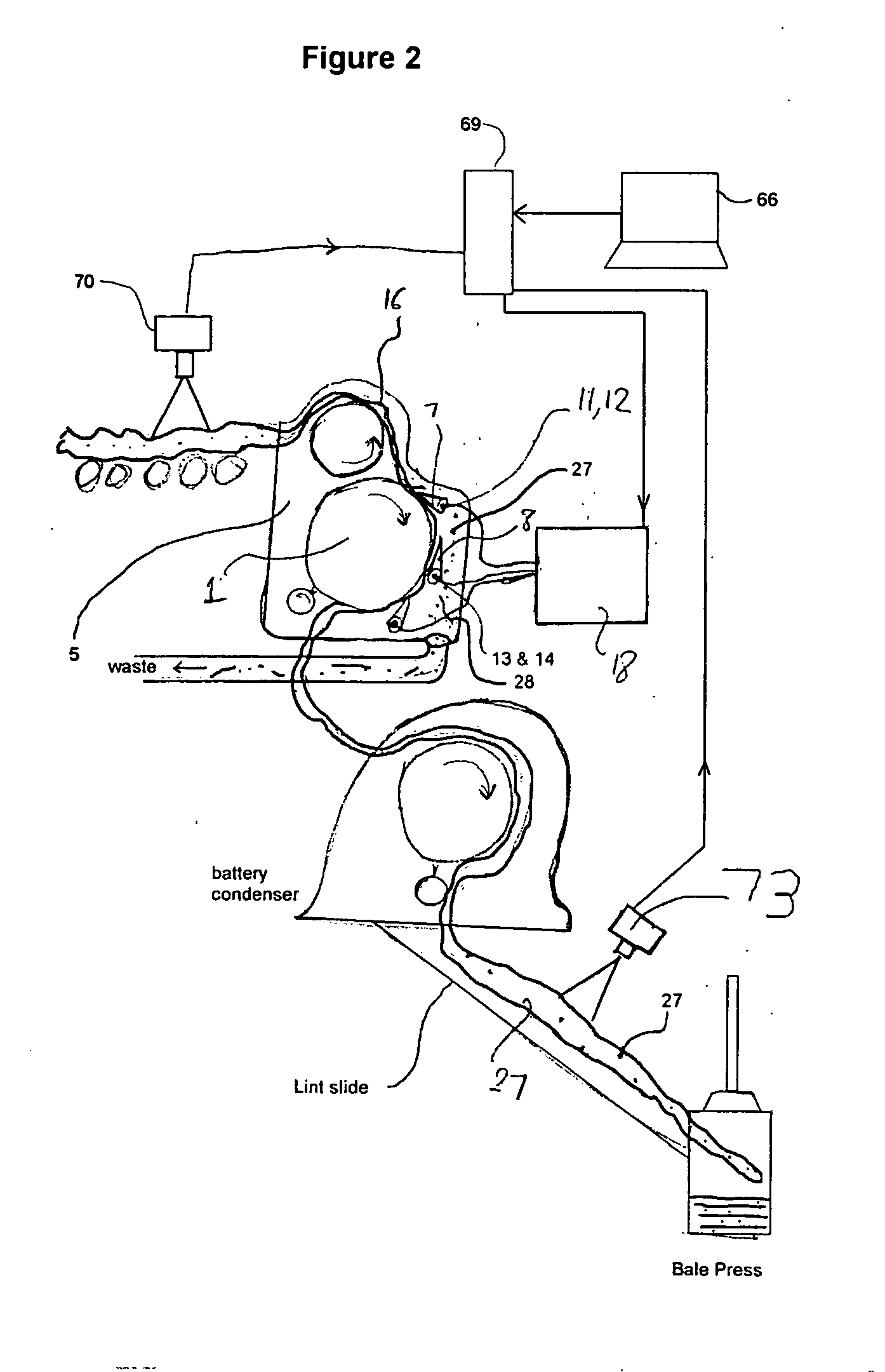

[0024] The invention of lint cleaning machine in a cotton processing facility such as cotton gin, is illustrated in FIG. 1. The lint cleaner is comprised of a battery of saws 1 containing multiple, round, narrow saws of the typical diameter ranging from 16 to 24 inches. All of the saws are spinning around the same axis 2 and driven by a single motor or mechanical drive or gear 3 through the shaft or belt 4. The motor or gear 3 is mounted on a stationary frame 5 of the lint cleaner, which also supports the housing and other components of the lint cleaner 6. On the frame 5 are several mounted grid bars 7 and 8 as shown in FIG. 1. The invention applies to the use of one or more grid bars in a lint cleaning machine. Each of the grid bars is mounted on a pivoting shaft 9 and 10. Electric motors 11, 12, 13 and 14, such as step motor with or without a gear, rotary solenoids or other actuators are coupled to the shafts, to controllably rotate the shafts. These grid bars are mounted respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com