Toothbrush container with twist vent-caps and integrated dental floss dispenser

a technology of toothbrush container and dental floss, which is applied in the field of toothbrush containers, can solve the problems of not providing a mechanism for enclosing the brush head of a dentifrice dispensing toothbrush, dental floss for cutting presents, and great difficulty for persons lacking finger dexterity, so as to prevent the drying of toothpaste, prevent the hardening of toothpaste, and enhance the sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Throughout the following detailed description, the same reference numerals refer to the same elements in all figures.

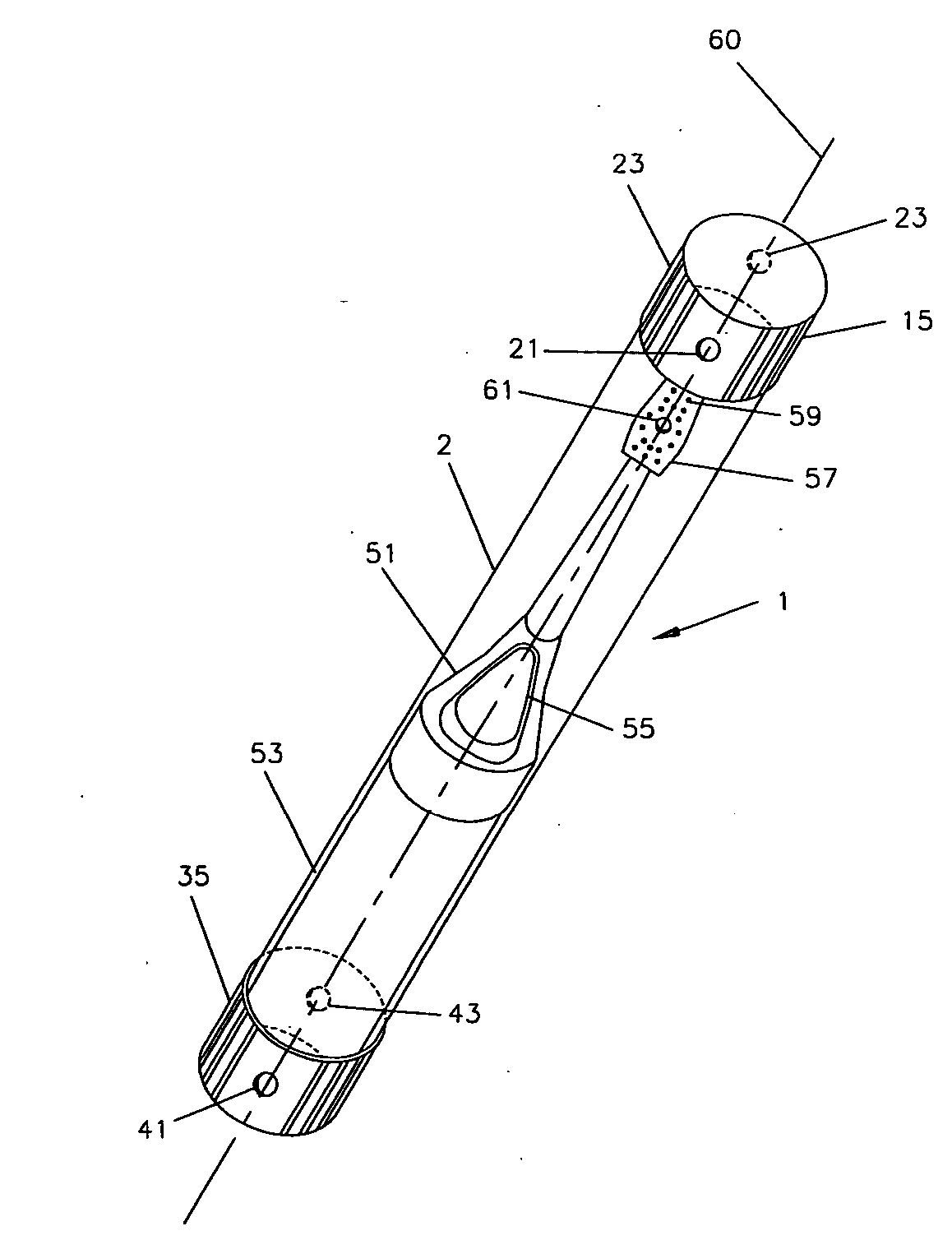

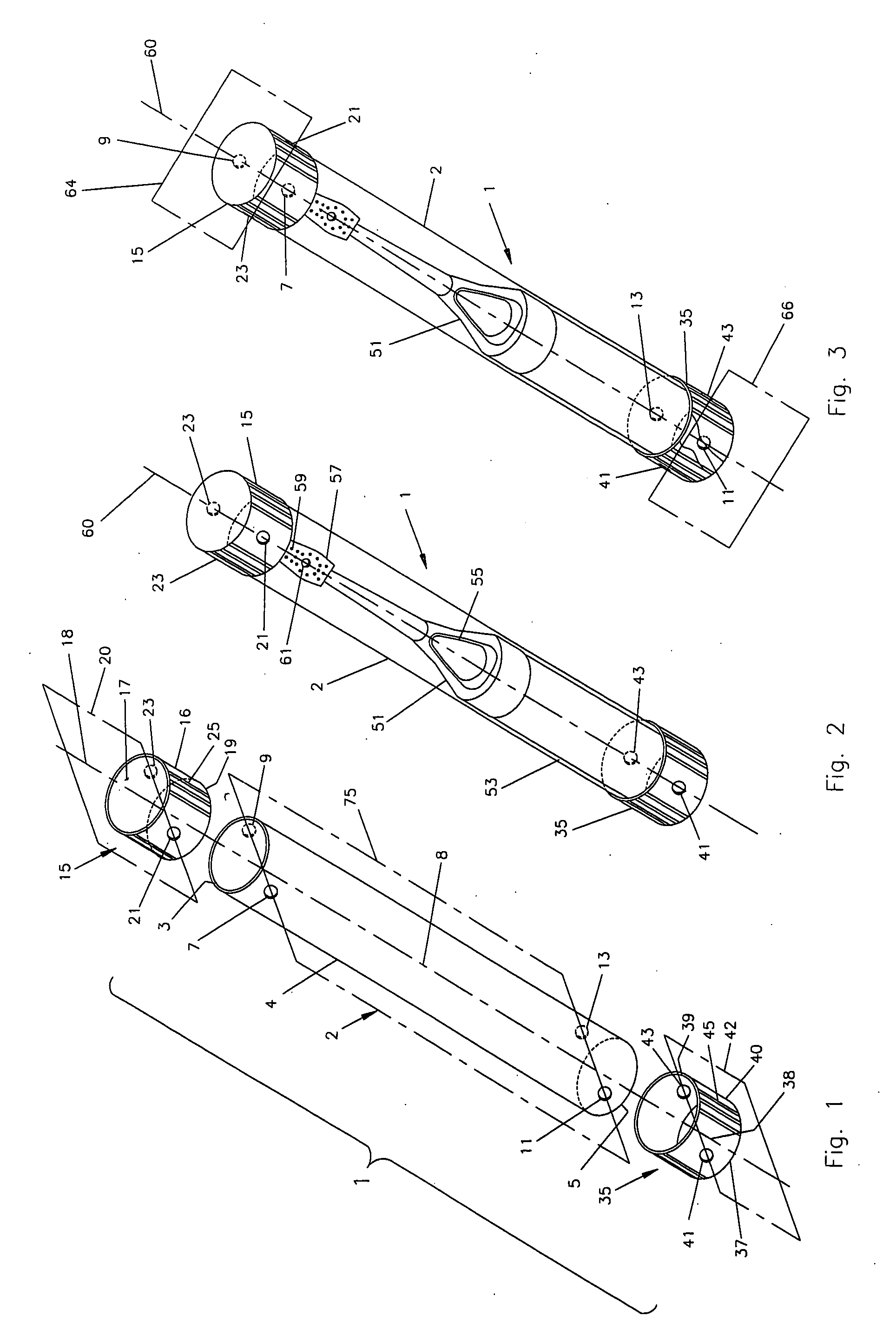

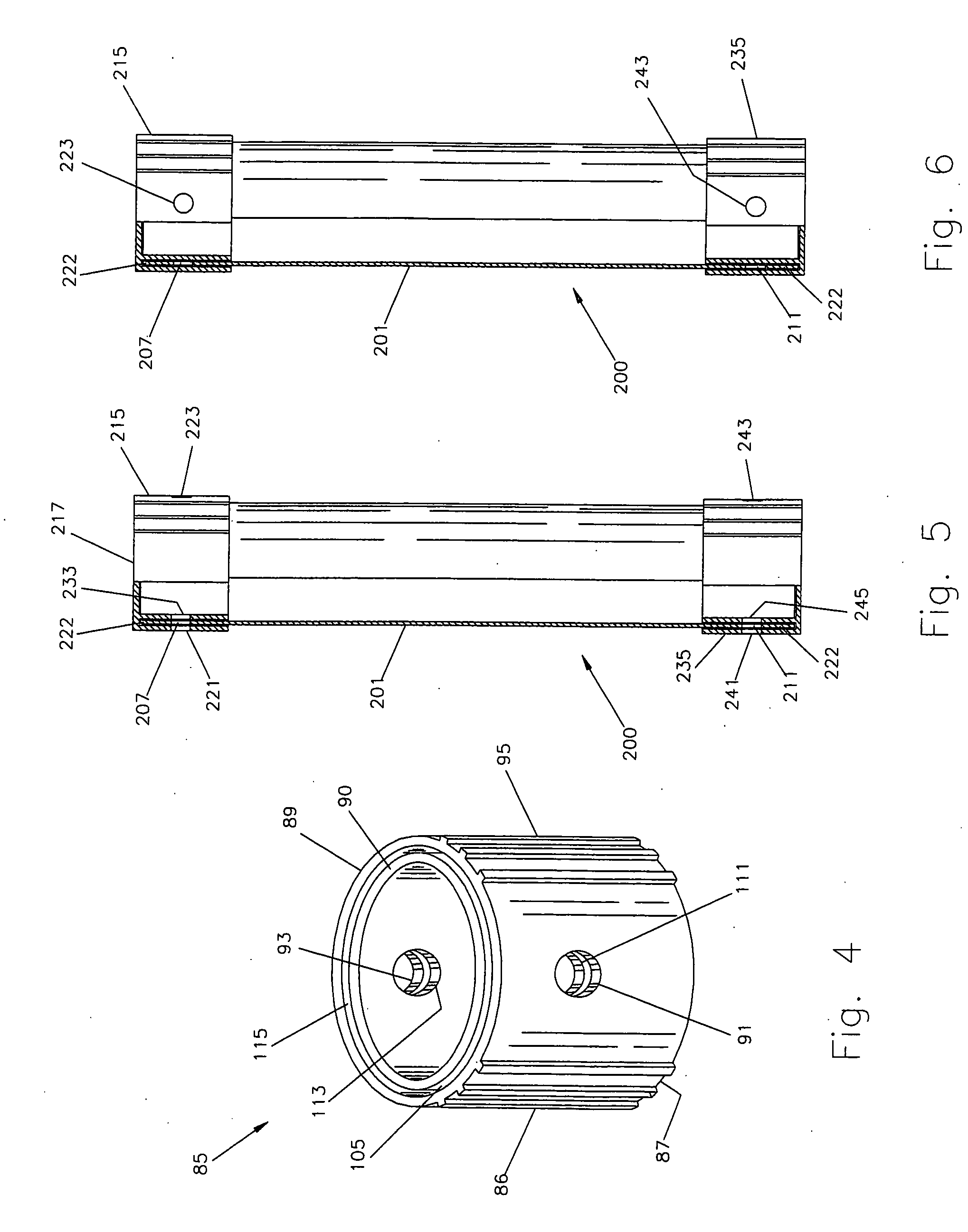

[0027] Referring to FIG. 1, a toothbrush container 1 for storing a dentifrice dispensing toothbrush of the present invention is shown in an exploded view. The toothbrush container 1 includes cylindrical circular hollow vent-tubing 2, top vent-cap 15 and bottom vent-cap 35. The cylindrical circular hollow vent-tubing 2 has annular wall 4 having top opening edge 3 and bottom opening edge 5 both being perpendicular to the longitudinal axis 8 of the vent-tubing 2. At an equal first distance from the top opening edge 3 are located a pair of opposing vent holes 7 and 9 and from the bottom opening edge are located at equal second distance a pair of opposing vent holes 11 and 13 on annular wall 4 with all hole centers being aligned on the same symmetry plane 75, which is in parallel and passing the longitudinal axis 8 of vent-tubing 2. Also shown in FIG. 1, the top ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com