Replacing chamber components in a vacuum environment

a vacuum environment and chamber technology, applied in vacuum evaporation coatings, chemical vapor deposition coatings, coatings, etc., can solve the problems of inability to meet the needs of the owner of the tool, inability to modify the wafer handling components of the processing tool, such as the transfer arm mechanism or the wafer handler, and cannot be required as a practical matter to achieve the effect of increasing throughpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In semiconductor processing systems, a number of processes are executed at reduced pressures. In order to reduce the maintenance time for processing modules, a maintenance system has been developed to replace consumable parts and other maintenance items without venting the process chamber / module to the atmosphere. Such maintenance items include consumable chamber components such as sputtering targets and other electrodes as well as members within a processing chamber such as clips, latches, shields, focus rings and structures having surfaces that can be eroded by etching or damaged by plasmas, heat, chemical reactions or other causes. Such maintenance items can also include chamber components that are susceptible to accumulations of deposits, such as shields, structural clamps and structural members, sensors, electrodes, clamps and latches, columnators, and other components exposed to deposition material, reactive gases, plasmas or other processing elements.

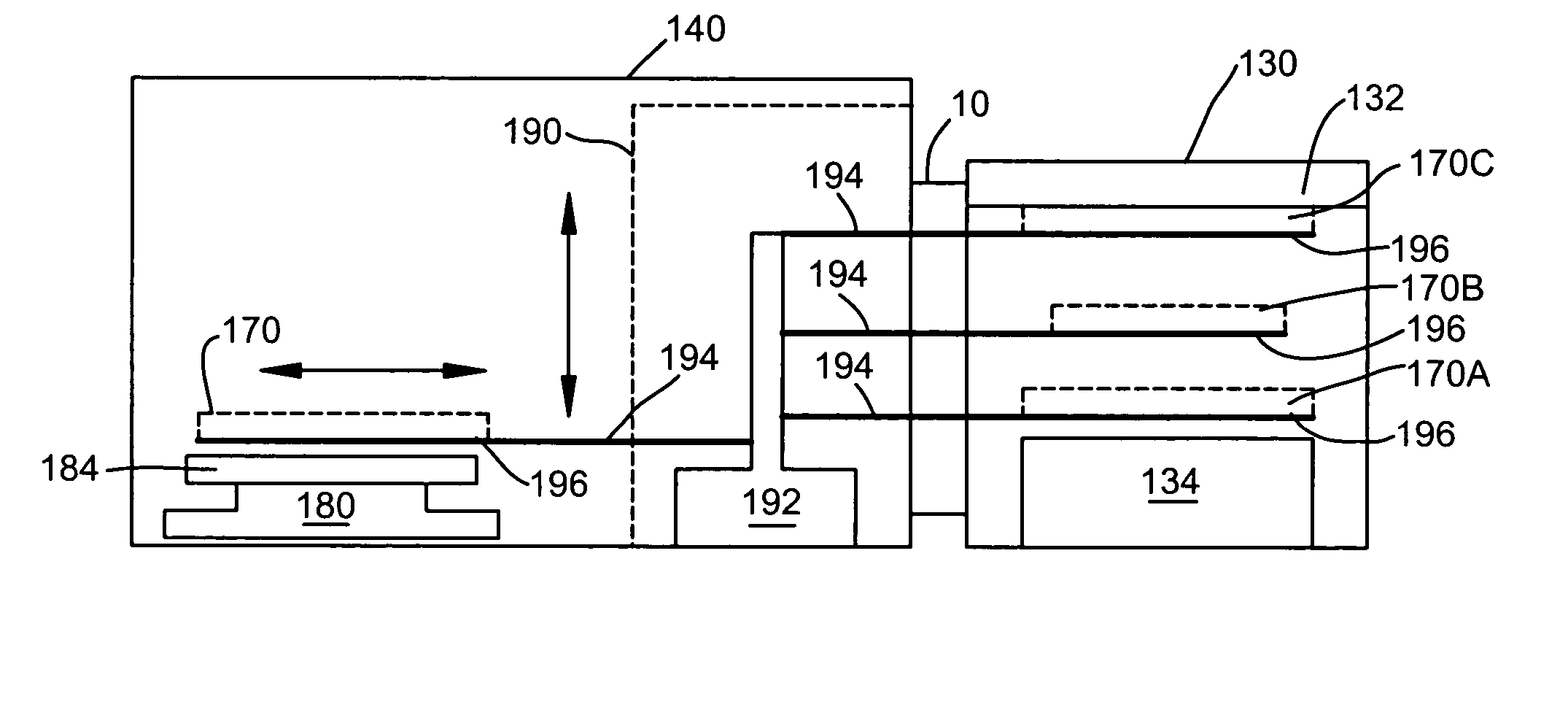

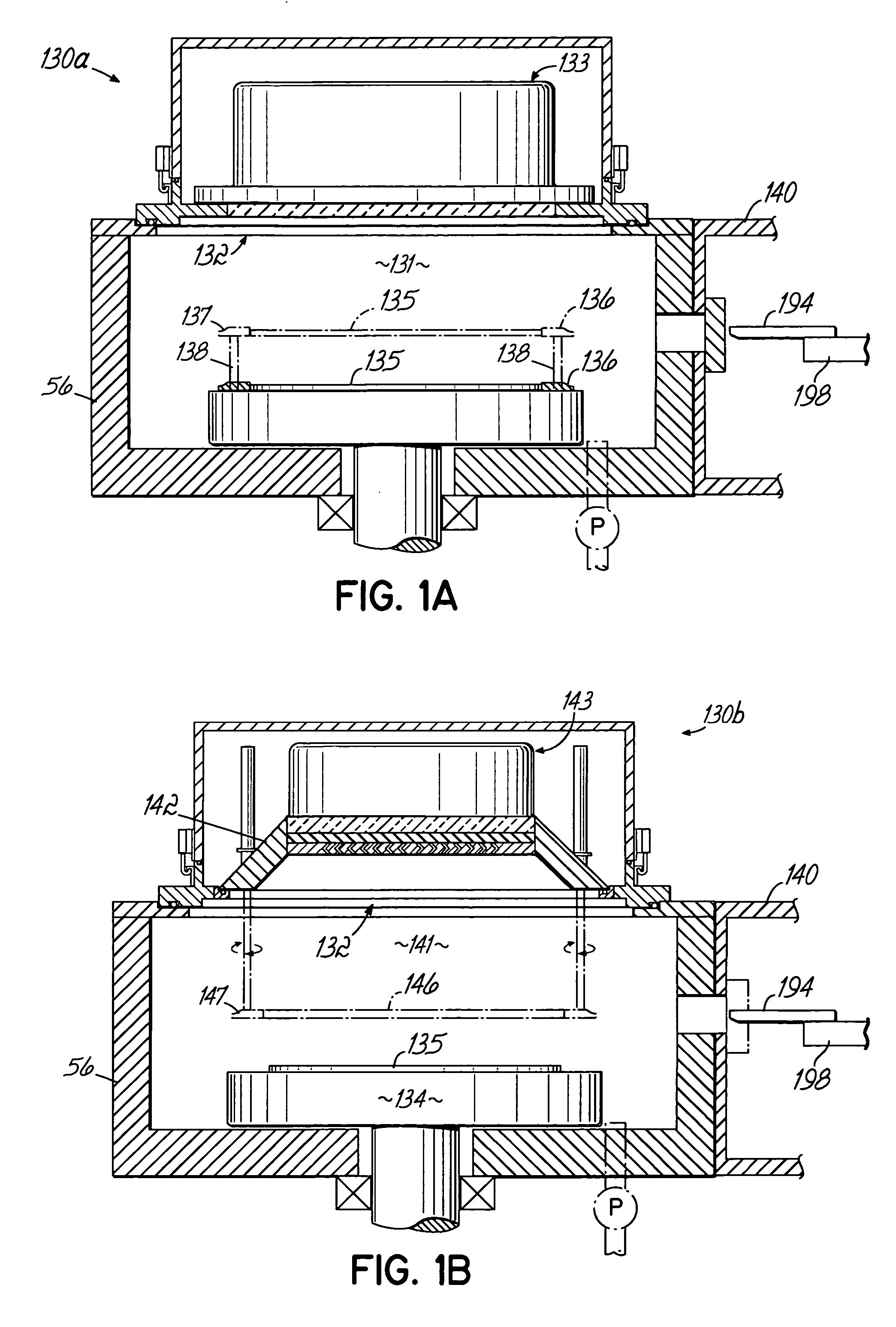

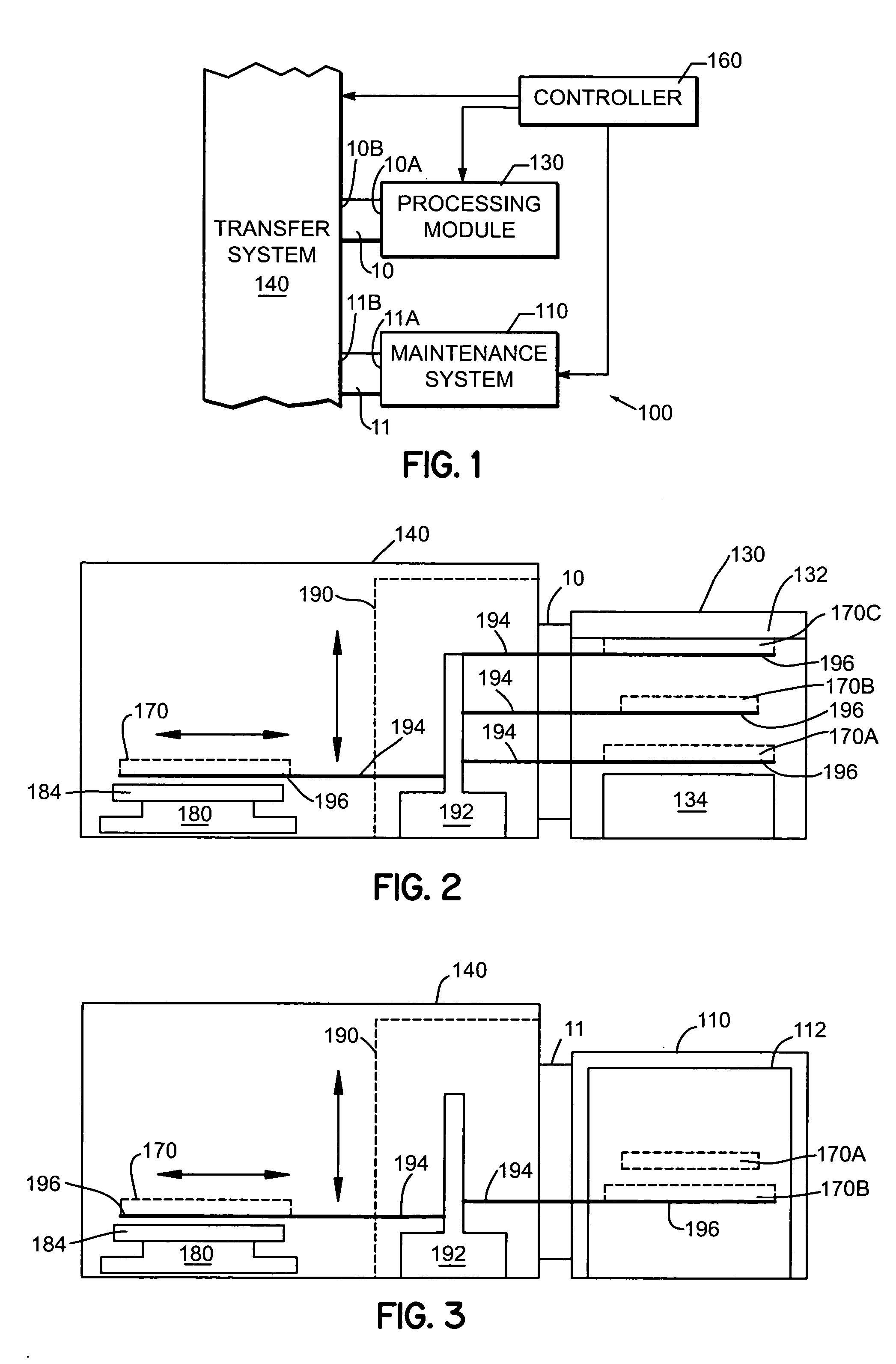

[0034]FIG. 1 illu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| vacuum environment | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com