Coating forming agent for reducing pattern dimension and method of forming fine pattern therewith

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

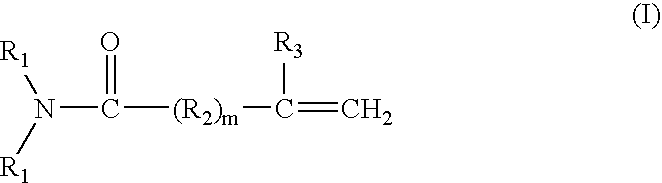

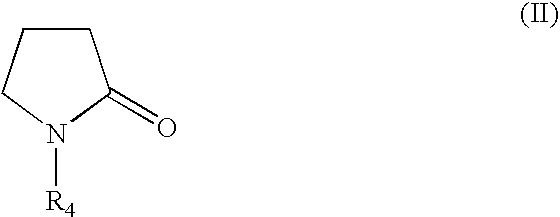

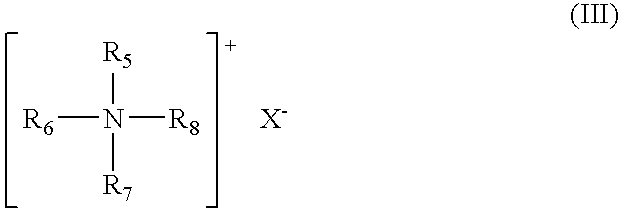

Method used

Image

Examples

example 1

[0080] A copolymer of acrylic acid and vinylpyrrolidone [5.83 g; acrylic acid / vinylpyrrolidone=2:1 (polymerization ratio)], triethanolamine (0.53 g), acrylamide (0.58 g) and “PLY-SURF A210G”, product of Dai-ichi Kogyo Seiyaku Co., as phosphate esters of polyoxyethylene surfactant (0.06 g) were dissolved in water (93 g) to prepare an over-coating agent.

[0081] A substrate was whirl coated with a positive-acting photoresist TArF-7a-52 EM (product of Tokyo Ohka Kogyo Co., Ltd.), and baked at 115° C. for 90 seconds to form a photoresist layer in a thickness of 0.40 μm.

[0082] The photoresist layer was exposed with a laser exposure unit (Nikon S-302 of Nikon Corp.), subjected to heat treatment at 100° C. for 90 seconds and developed with an aqueous solution of 2.38 mass % TMAH (tetramethylammonium hydroxide) to form photoresist patterns which defined hole patterns with an each diameter of 161.0 nm.

[0083] Then above-described over-coating agent was applied onto the substrate including th...

example 2

[0084] A copolymer of acrylic acid and vinylpyrrolidone [6.14 g; acrylic acid / vinylpyrrolidone=2:1 (polymerization ratio)], glycerol (0.18 g), acrylamide (0.62 g) and “PLYSURF A210G”, product of Dai-ichi Kogyo Seiyaku Co., as phosphate esters of polyoxyethylene surfactant (0.06 g) were dissolved in water (93 g) to prepare an over-coating agent.

[0085] Then above-described over-coating agent was applied onto the substrate including the hole patterns (each diameter of patterns: 161.0 nm) which was prepared in the same manner as described in EXAMPLE 1, and subjected to heat treatment at 150° C. for 60 seconds. Subsequently, the over-coating agent was removed using pure water at 23° C. The each diameter of the hole patterns was reduced to 121.7 nm.

example 3

[0086] A copolymer of acrylic acid and vinylpyrrolidone [6.14 g; acrylic acid / vinylpyrrolidone=2:1 (polymerization ratio)], glycerol (0.18 g), methacrylamide (0.62 g) and “PLYSURF A210G”, product of Dai-ichi Kogyo Seiyaku Co., as phosphate esters of polyoxyethylene surfactant (0.06 g) were dissolved in water (93 g) to prepare an over-coating agent.

[0087] Then above-described over-coating agent was applied onto the substrate including the hole patterns (each diameter of patterns: 161.0 nm) which was prepared in the same manner as described in EXAMPLE 1, and subjected to heat treatment at 150° C. for 60 seconds. Subsequently, the over-coating agent was removed using pure water at 23° C. The each diameter of the hole patterns was reduced to 122.6 nm.

[Second Type of the Over-Coating Agent for Forming Fine Patterns]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com