Refrigeration source for a cryoablation catheter

a cryoablation catheter and refrigeration source technology, which is applied in the direction of catheters, domestic cooling devices, lighting and heating devices, etc., can solve the problems of radiofrequency energy not being able to safely produce circumferential lesions without serious complications, matrix collapse, radiofrequency energy being known to damage the lining of the heart, etc., and achieves a small flow diameter. , the effect of significantly reducing the cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

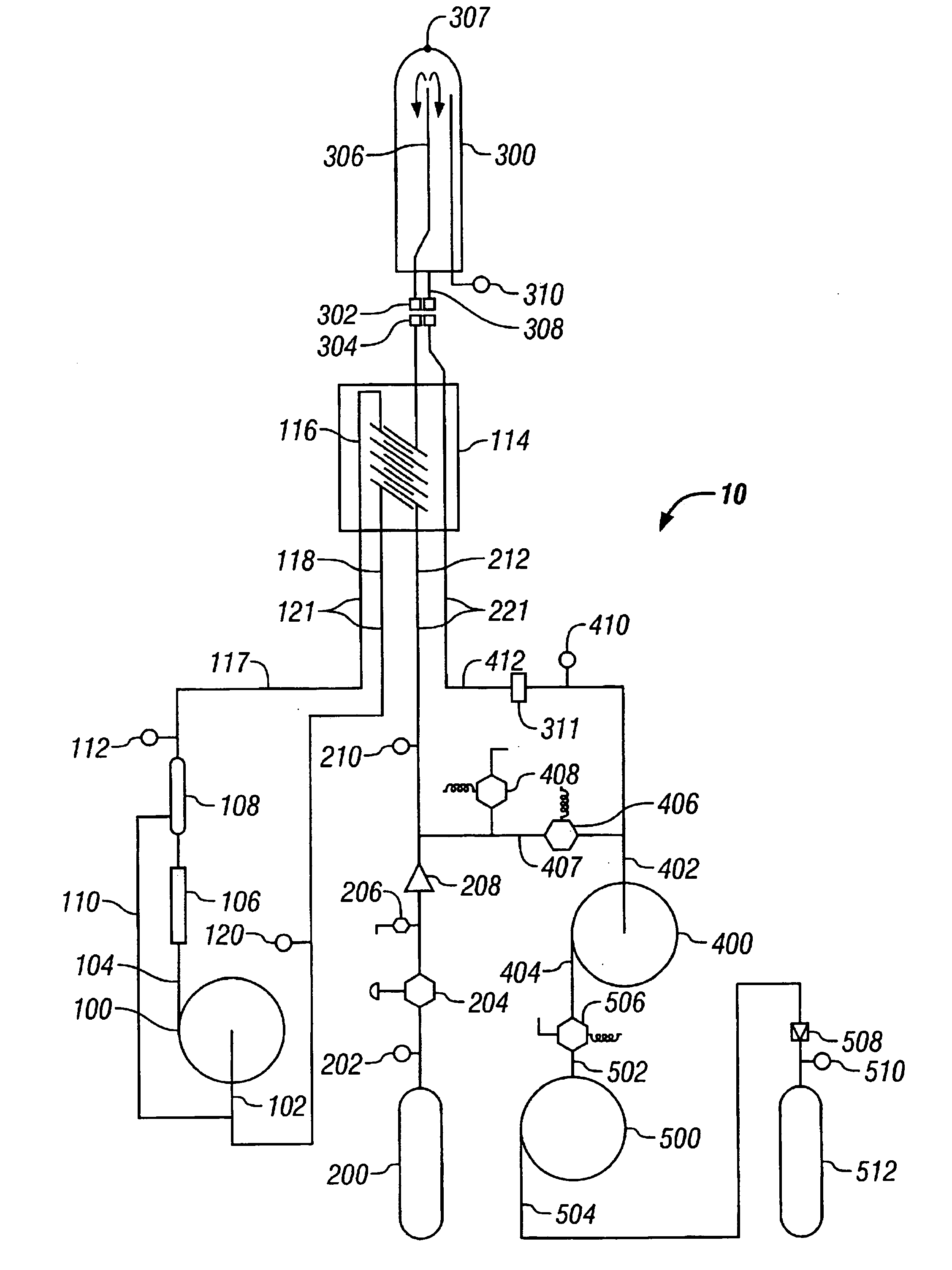

[0030]FIG. 1 is a schematic of the apparatus of the present invention, using a pressure bottle as the primary refrigerant source;

second embodiment

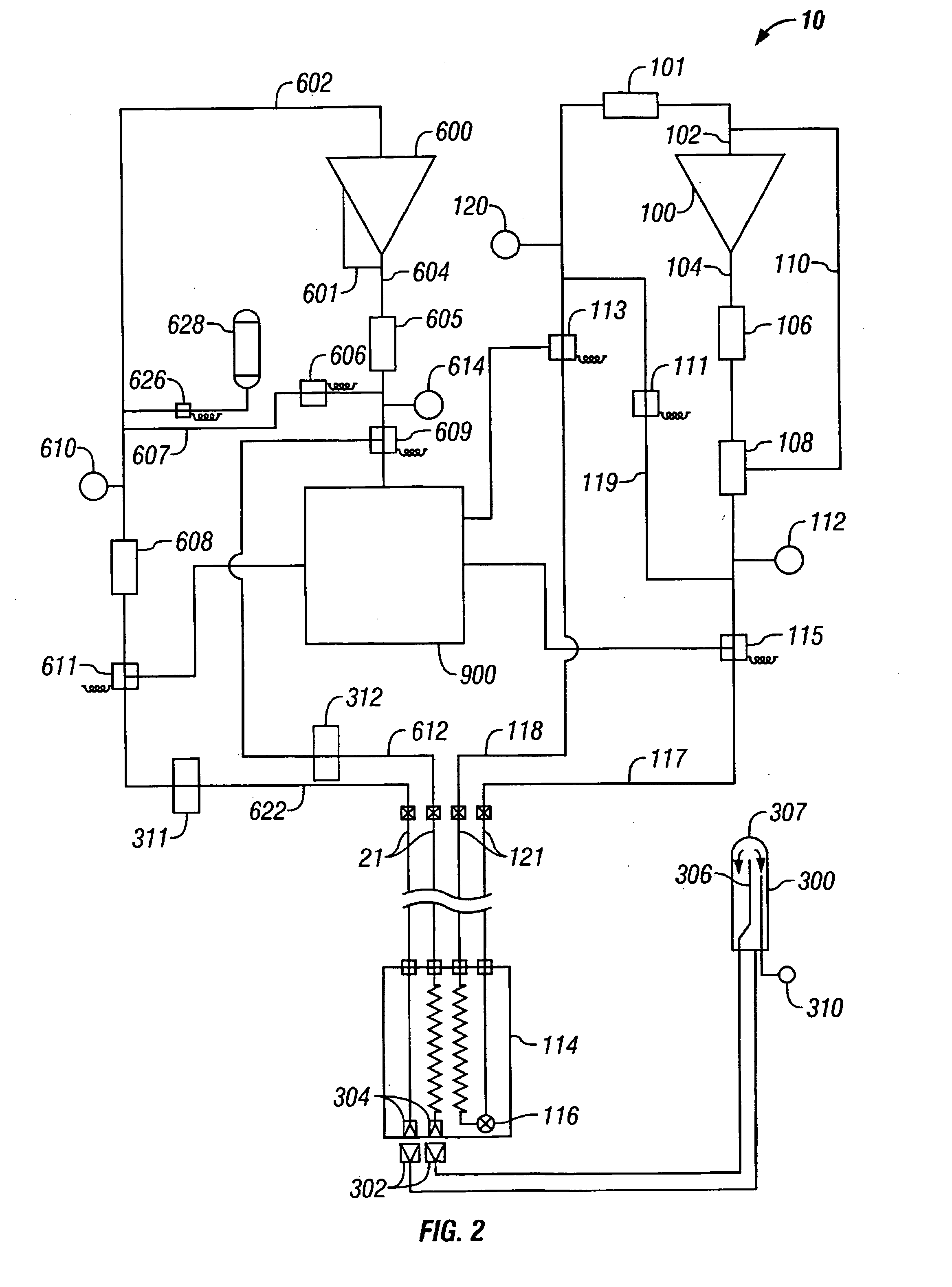

[0031]FIG. 2 is a schematic of the apparatus of the present invention, using a compressor as the primary refrigerant source;

third embodiment

[0032]FIG. 3 is a schematic of the apparatus of the present invention, using two compressors connected in series as the primary refrigerant source;

[0033]FIG. 4 is a schematic of a first embodiment of a control system apparatus according to the present invention, for use with the apparatus shown in FIG. 1;

[0034]FIG. 5 is a schematic of a second embodiment of a control system apparatus according to the present invention, for use with the apparatus shown in FIG. 2 or 3;

[0035]FIG. 6 is a schematic of a parameter display for use with the control equipment of the present invention; and

[0036]FIG. 7 is a flow diagram showing one control sequence for use with the control apparatus of the present invention.

[0037]FIG. 8 is a perspective view of the system of the present invention;

[0038]FIG. 9 is a cross-sectional view of the catheter of the present invention as seen along the line 2-2 in FIG. 8;

[0039]FIG. 10 is a schematic view of the computer and its interaction with system components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com