Donor sheet, color filter, organic EL element and method for producing them

a technology of organic el elements and donor sheets, applied in the field of laser beam thermal imaging process, can solve the problems of complex processing devices, complicated working, and many conventional methods for forming black matrix, and achieve the effects of reducing manufacturing steps, high contrast, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) Production of Donor Sheet

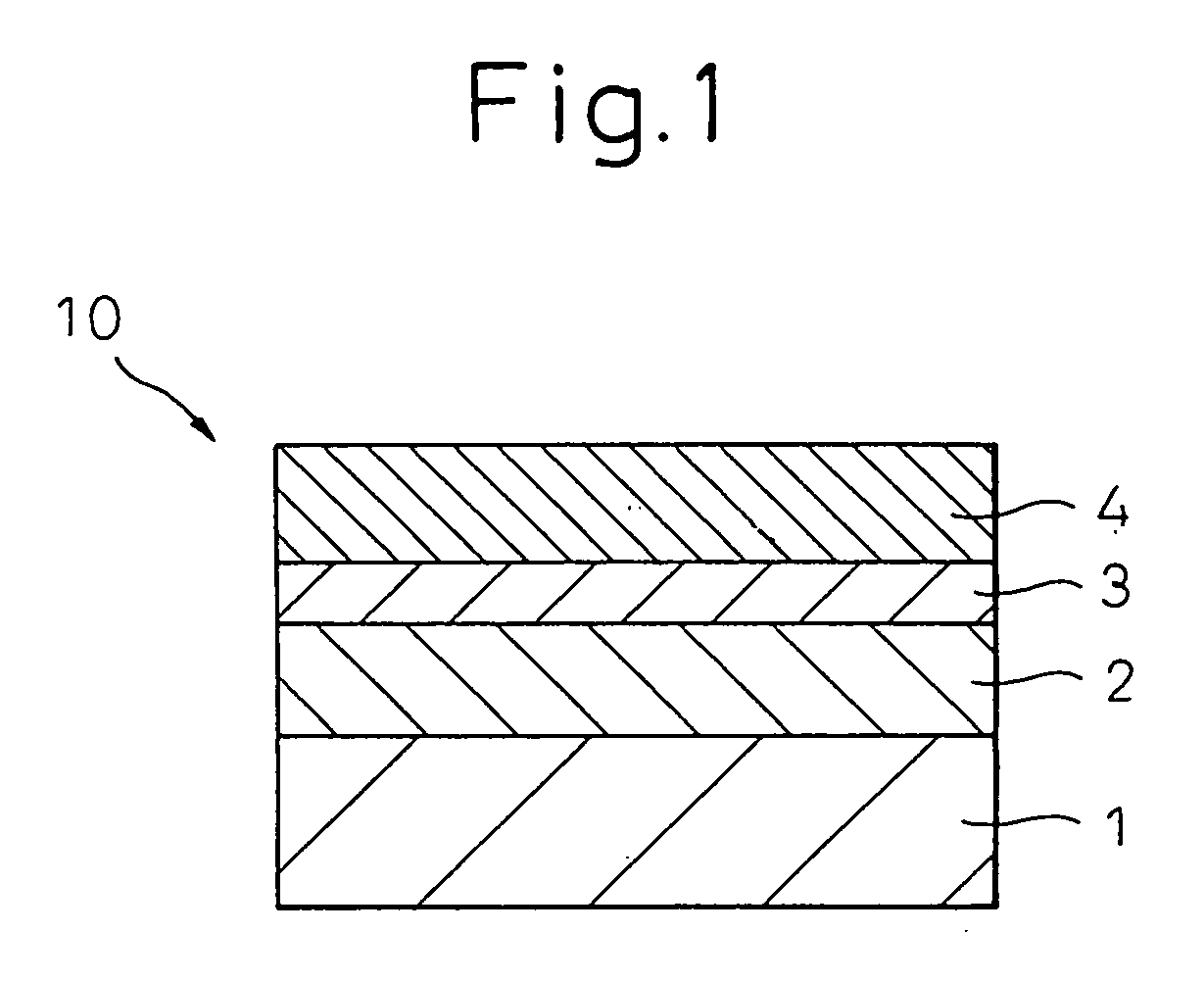

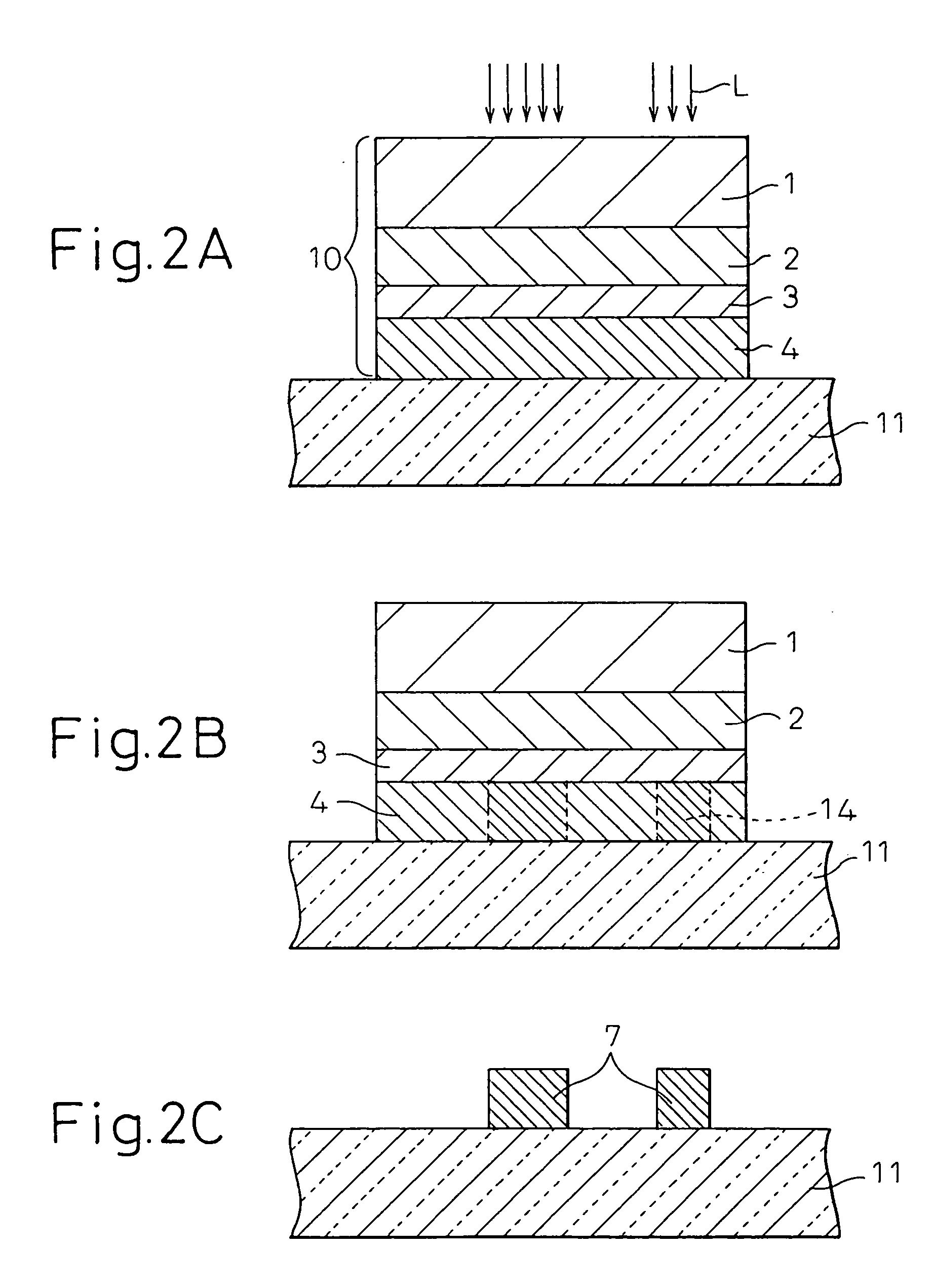

[0133] A donor sheet comprising a base, a light-to-heat conversion layer, an intermediate layer and a transfer layer, said layers being formed on the base, was produced according to the following procedure.

[0134] After a polyethylene terephthalate (PET) film having a thickness of 75 μm was prepared as a base, a light-to-heat conversion layer (LTHC layer), an intermediate layer and a transfer layer each having the following composition and film thickness were formed in the order as described below. The (LTHC layer) and the intermediate layer were coated with die coating method, followed by being cured by irradiation with ultraviolet rays, and then the transfer layer was similarly formed with die coating method.

Light-to-heat conversion layerCarbon black100.0% by weight(trade name: “Raben 760”, manufacturedby Colombian Carbon Co.)Dispersant 8.9% by weight(trade name: “Disperbyk 161”, manufacturedby BYK-Cheimie Co.)Vinyl butyral resin 17.9% by weight(tr...

example 2

[0147] The procedure of Example 1 was repeated with the proviso that, in this example, a glass substrate with chromium (Cr) black matrix (hereinafter, referred to as “CrBM”) was used in place of the glass substrate, and a separation rib was produced on the black matrix of the substrate in accordance with the following method.

[0148] Using an exclusive LITI machine (laser beam thermal transfer machine, wavelength of laser beam: 1064 nm), a separation rib was laid on a glass substrate provided with a black matrix. The donor sheet produced in Example 1 was laid on the black matrix side of the glass substrate, and then laser beam was irradiated from the side of the donor sheet in the same striped pattern as that of the black matrix under the conditions of an output of 11 W, a scan speed of 15m / s and an irradiation width of 20 μm. Then, baking was conducted in an oven at 230° C. for 1 hour so as to cure and adhere the transferred portion. A separation rib having a width of 20 μm and a th...

example 3

[0156] The procedure of Example 1 was repeated with the proviso that, in this example, a solvent-based color ink was used as in Comparative Example 1, and an amount of the fluororesin added was changed from 0.05% by weight to 7.62% by weight.

[0157] The evaluation test similar to that of Example 1 was carried out using the resulting glass substate with the partition pattern (black matrix). As shown in the following Table 1, the contact angle was 45°, the critical surface tension was 20 dyne / cm, no color mixture was observed, and the color spot was rated “good”.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com