Packaging apparatus and method

a technology of packaging apparatus and method, applied in the field of packaging, can solve the problems of product damage during shipping, extreme cost associated with the molds to create the eps insulation, and product damage during shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail preferred embodiments of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to the embodiments illustrated.

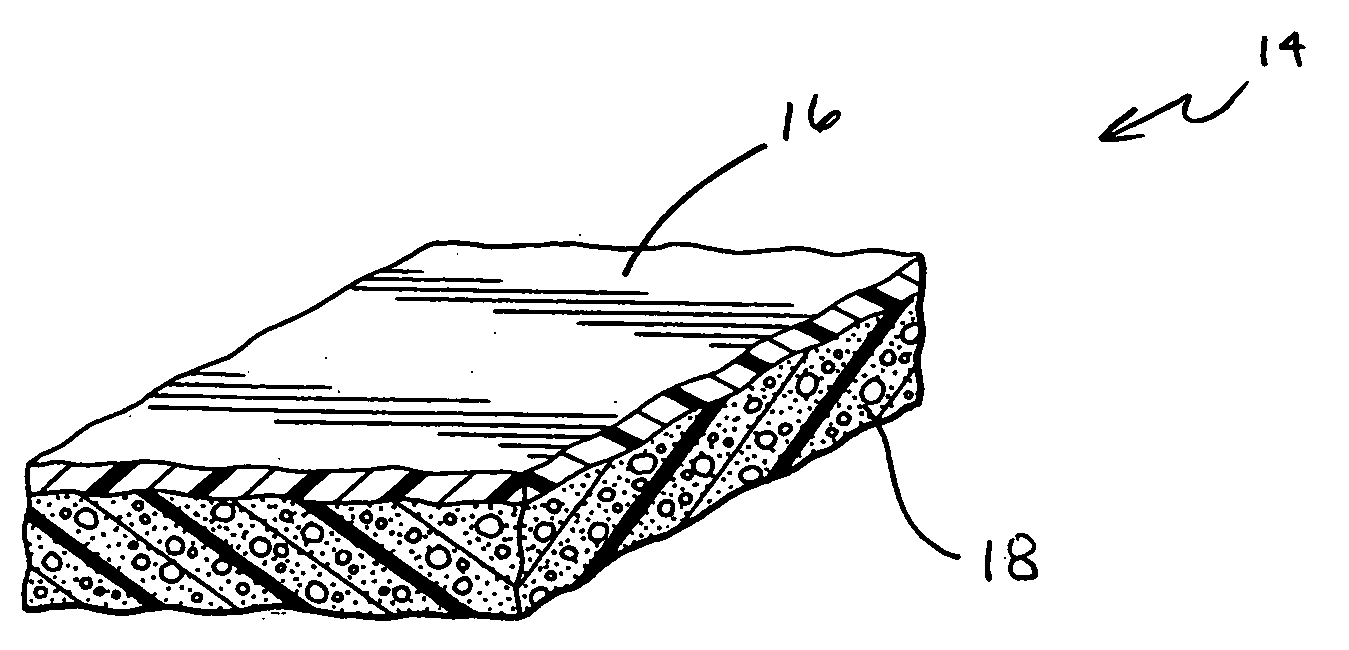

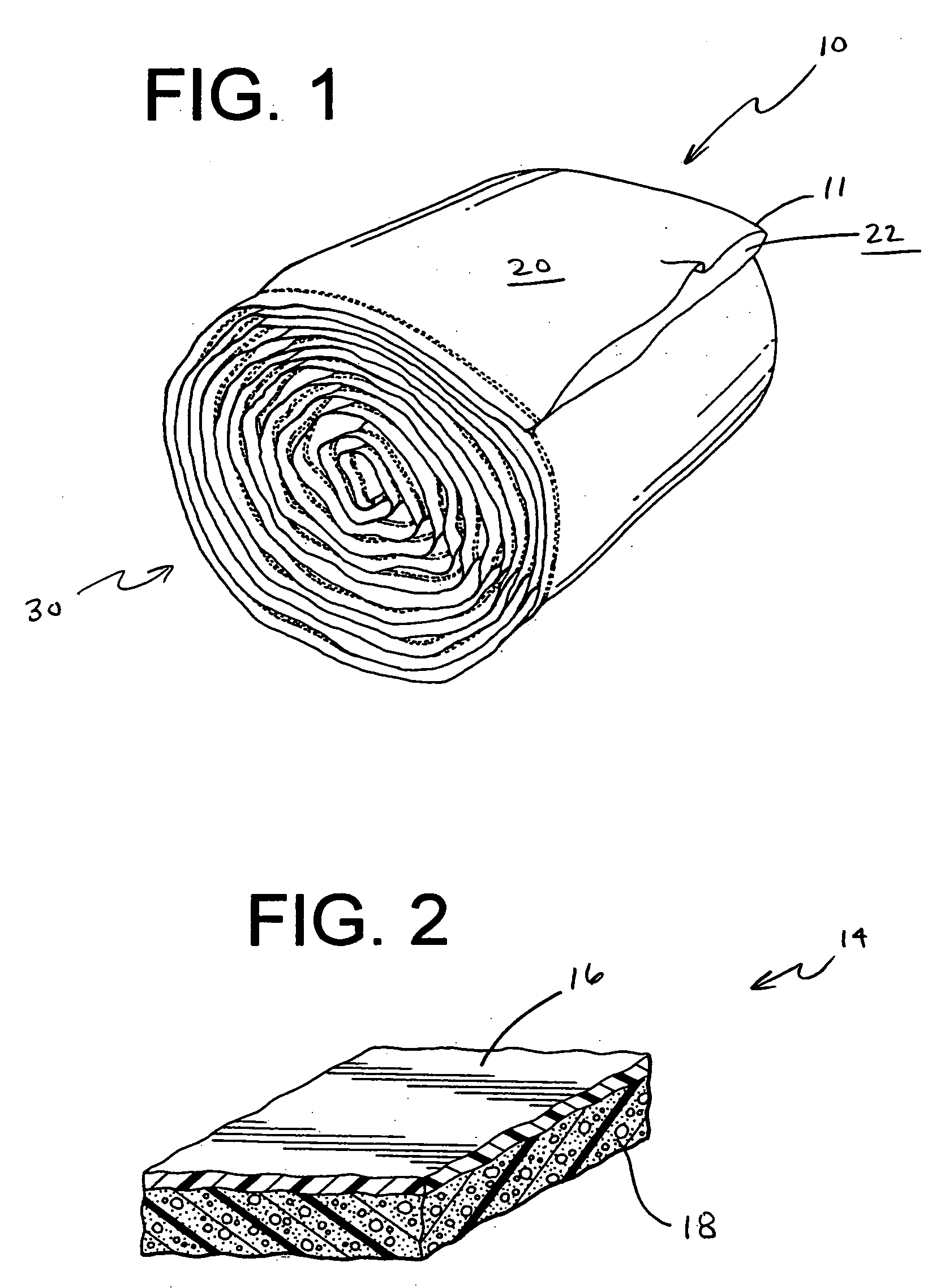

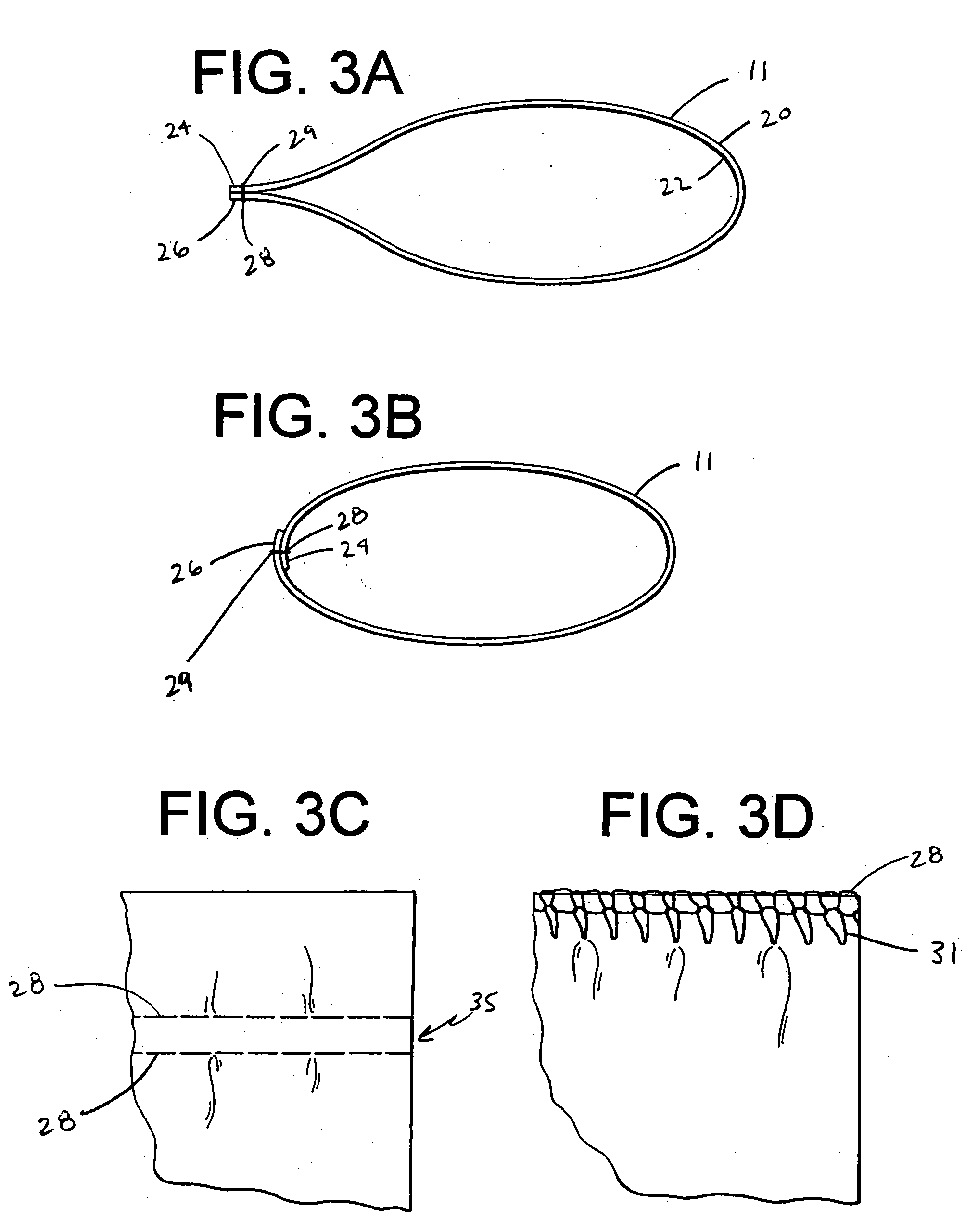

[0052] Referring now in detail to the FIGS., and initially to FIG. 1, there is shown a covering 10 utilized as a protective overwrapping 10 for products during various steps in the material handling process of the products. As explained above, for purposes of this disclosure, the term “material handling” is intended to refer to any or all of the processes and factors relevant to the staging, organizing, storing, locating, loading, moving, shipping, unloading, wrapping, tracking, protecting and generally the overall safety and preservation of the products. In a preferred embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com