Non-contact cool-down station for wafers

a technology of cool-down station and wafer, which is applied in the direction of domestic cooling apparatus, furniture, lighting and heating apparatus, etc., can solve the problems of damage to the cassette, inability to transport the wafer from the process chamber immediately,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

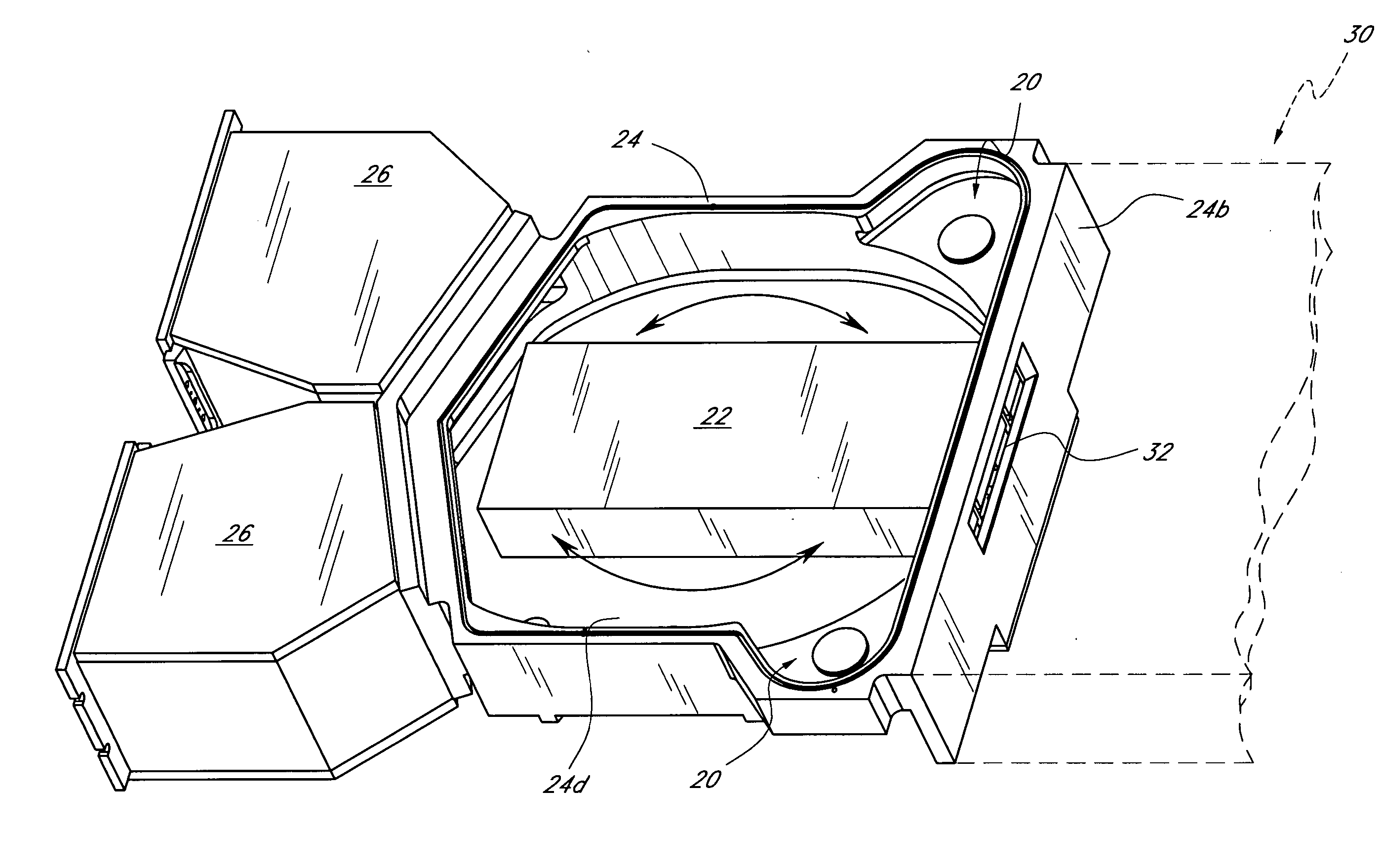

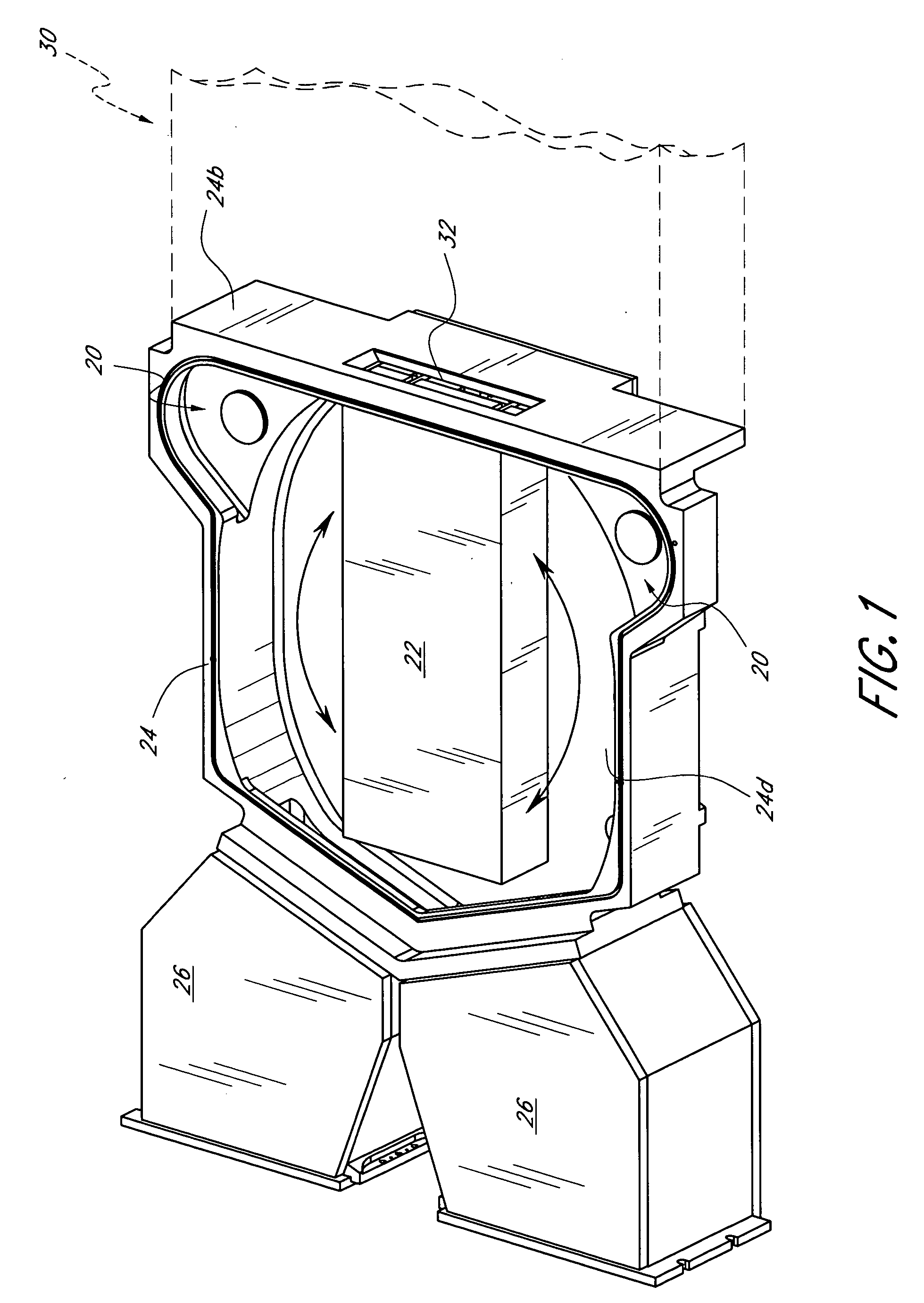

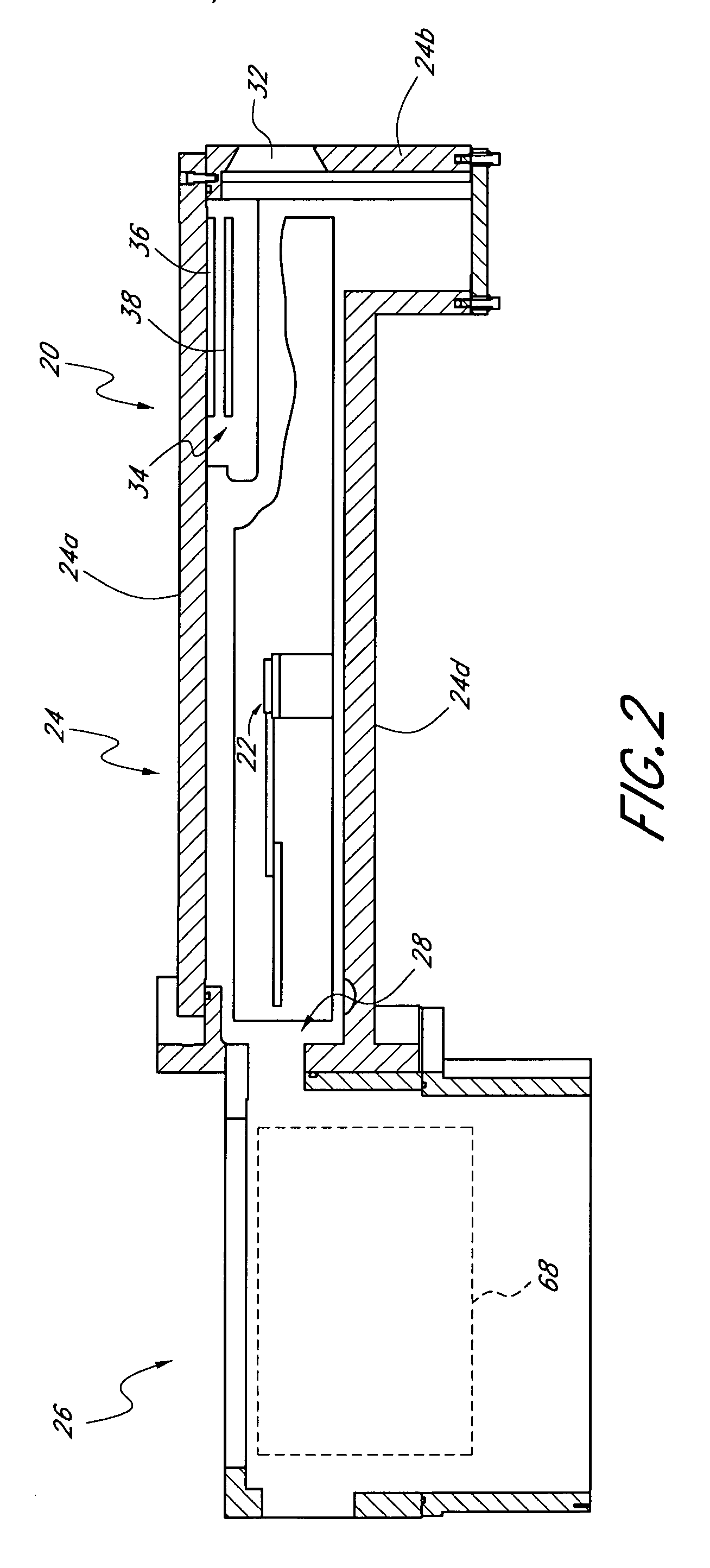

[0019] In the illustrated embodiments, a wafer station is provided in which a semiconductor wafer or substrate is held suspended by gas flowing across a major surface of the substrate in accordance with Bernoulli's principle. By this flow of gas, the substrate can be suspended without a horizontal surface of the substrate contacting another surface for vertical support. Advantageously, the wafer station can be used as a cooling station to cool substrates after undergoing semiconductor processing. In such an arrangement, the gas flowing across the major surface can be a cooling gas that cools the substrate as it flows across the major surface. In other arrangements, the wafer station can be used as a staging area to temporarily hold a wafer before the wafer is transported elsewhere.

[0020] In suspending the substrate by taking advantage of the Bernoulli principle, the wafer station operates in a manner similar to a class of semiconductor pick-up devices called Bernoulli wands. Bernou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com