Display device and method of fabricating the same

a display device and active matrix technology, applied in semiconductor devices, instruments, optics, etc., can solve the problems of inability to form a circuit on silicon wafers, the thickness of the driver circuit is an obstacle to miniaturizing the whole display device, and the number of terminals of the integrated circuit is very large, so as to achieve the effect of reducing weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

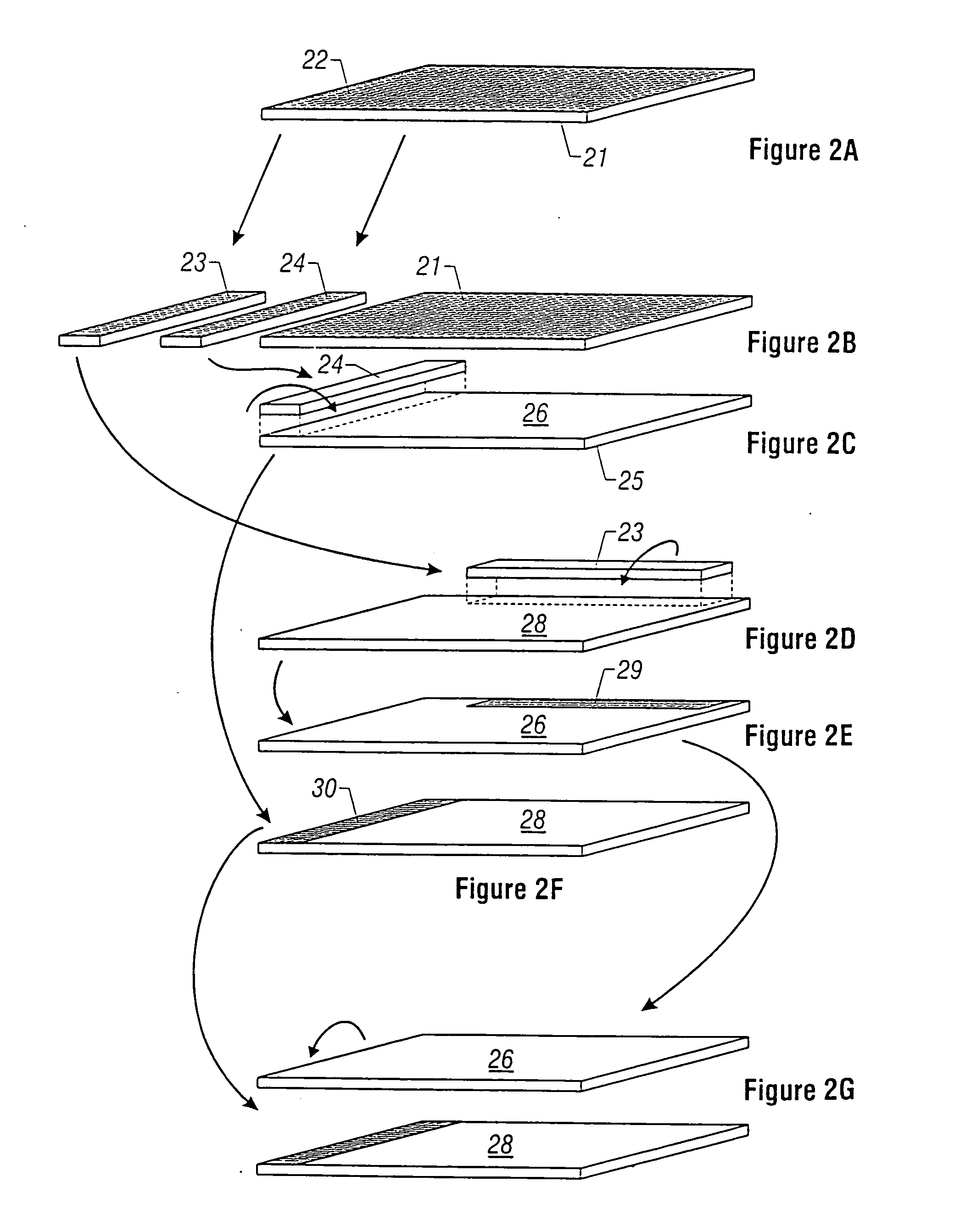

[0045] Manufacturing steps for fabricating one substrate of a passive matrix liquid crystal display are briefly described now. The present example is described by referring to FIGS. 4(A)-4(C) and 5(A)-5(D). Steps for forming a driver circuit on a stick crystal are schematically shown in FIGS. 4(A)-4(C). Steps for mounting the stick crystal on the substrate of the liquid crystal display are schematically shown in FIGS. 5(A)-5(D).

[0046] First, a silicon film having a thickness of 3000 Å was deposited as a peeling layer 32 on a glass substrate 31. Since the silicon film becoming the peeling layer 32 is etched away when circuitry and a substrate formed on the silicon film are separated, the quality of the silicon film will present almost no problems. Therefore, the silicon film may be deposited by a method which permits mass production. Furthermore, the silicon film may be either amorphous or crystalline in character.

[0047] The glass substrate may be made of Corning 7059 glass, Cornin...

example 2

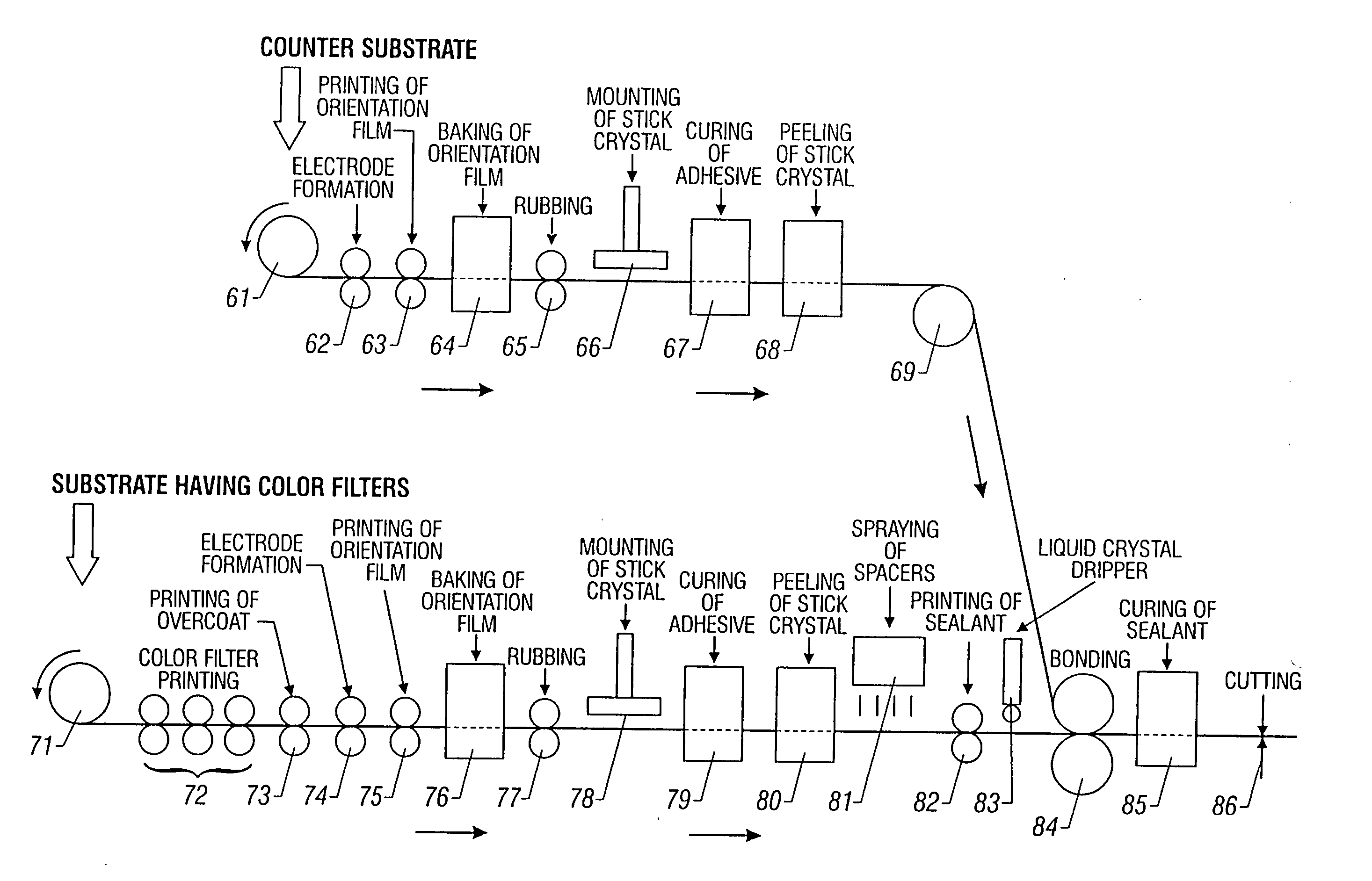

[0060] The present example relates to a method (referred to as the roll-to-roll method) of successively fabricating filmy passive matrix liquid crystal displays. A production system for implementing the present example is shown in FIG. 6. The substrate material for obtaining the filmy liquid crystal displays may be selected from polyethylene sulfite, poly-carbonate, and polyimide. Since polyethylene terephthalate and polyethylene naphthalate are polycrystalline plastics, they are not appropriate as liquid crystal materials which provide displays making use of polarization of light.

[0061] The production system shown in FIG. 6 is divided into two major parts: the upper portion and the lower portion. In the lower portion, a substrate on which color filters are formed is fabricated as a component of a liquid crystal display. In the upper portion, a counter substrate is manufactured. First, steps for fabricating the substrate on which the color filters are formed are described.

[0062] C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com