Pipe burying method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

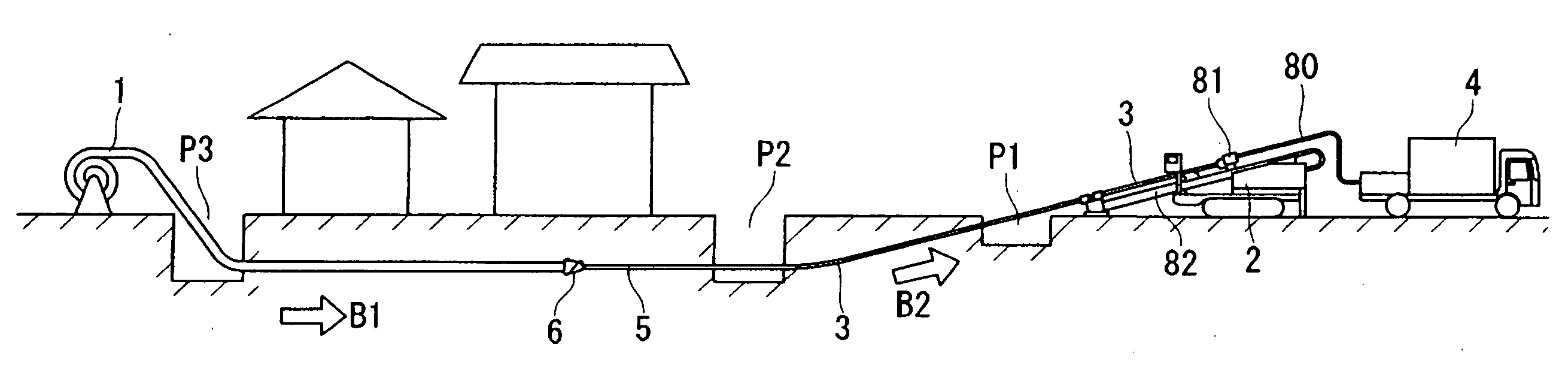

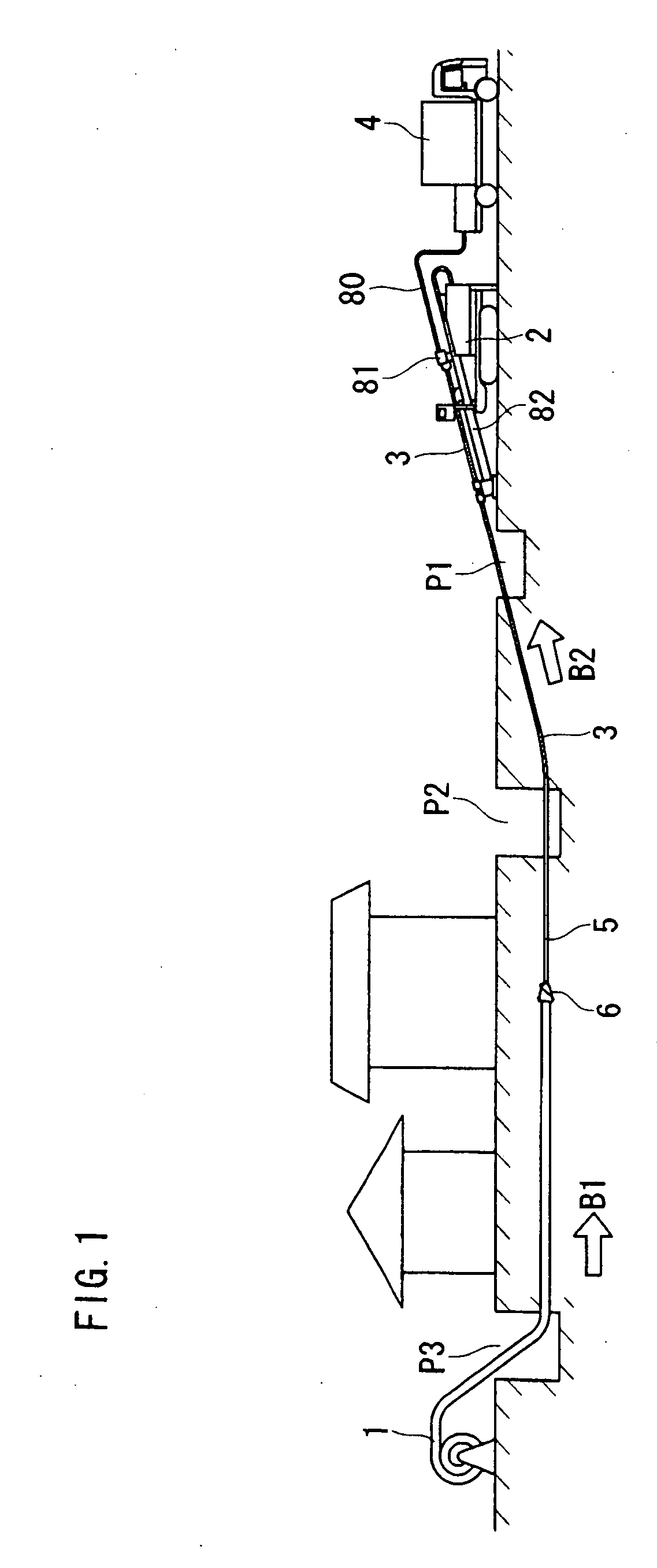

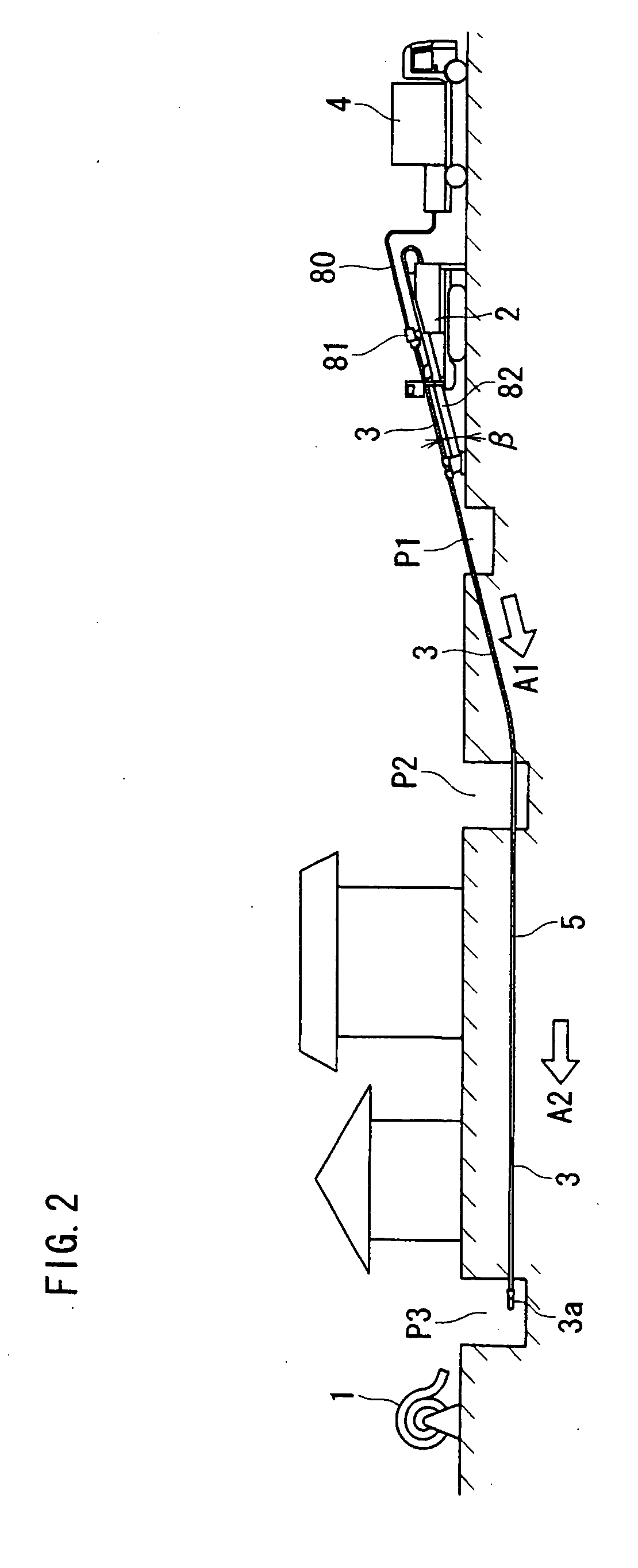

[0032] In the following, with reference to the drawings, embodiments of the pipe burying method according to the present invention will be described in detail below. In this pipe burying method, the above-described horizontal drill construction is employed and a ground boring machine shown in FIGS. 1 and 2 is used. According to the pipe burying method, at first, a pilot hole 5 as shown in FIG. 2 is formed. This pilot hole 5 is formed by the above-described operation shown in FIG. 10 and this operation will be briefly described below with reference to FIG. 1. At first, as shown in FIG. 2, a penetration pit P1, a starting pit P2, and an attainment pit P3 are formed on the earth at certain intervals each other. Then, on a drill driving device 2, a rod (a hollow rod) 3 with a leading body (a pilot head) 3a fit at its front end is installed to be supported. Then, while emitting the drilling fluid (a crystal water, a muddy water, and a bentonite muddy water or the like) that is pressure-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com