Optical compensatory sheet producing method and apparatus, thermal treating method and apparatus, and dust removing method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

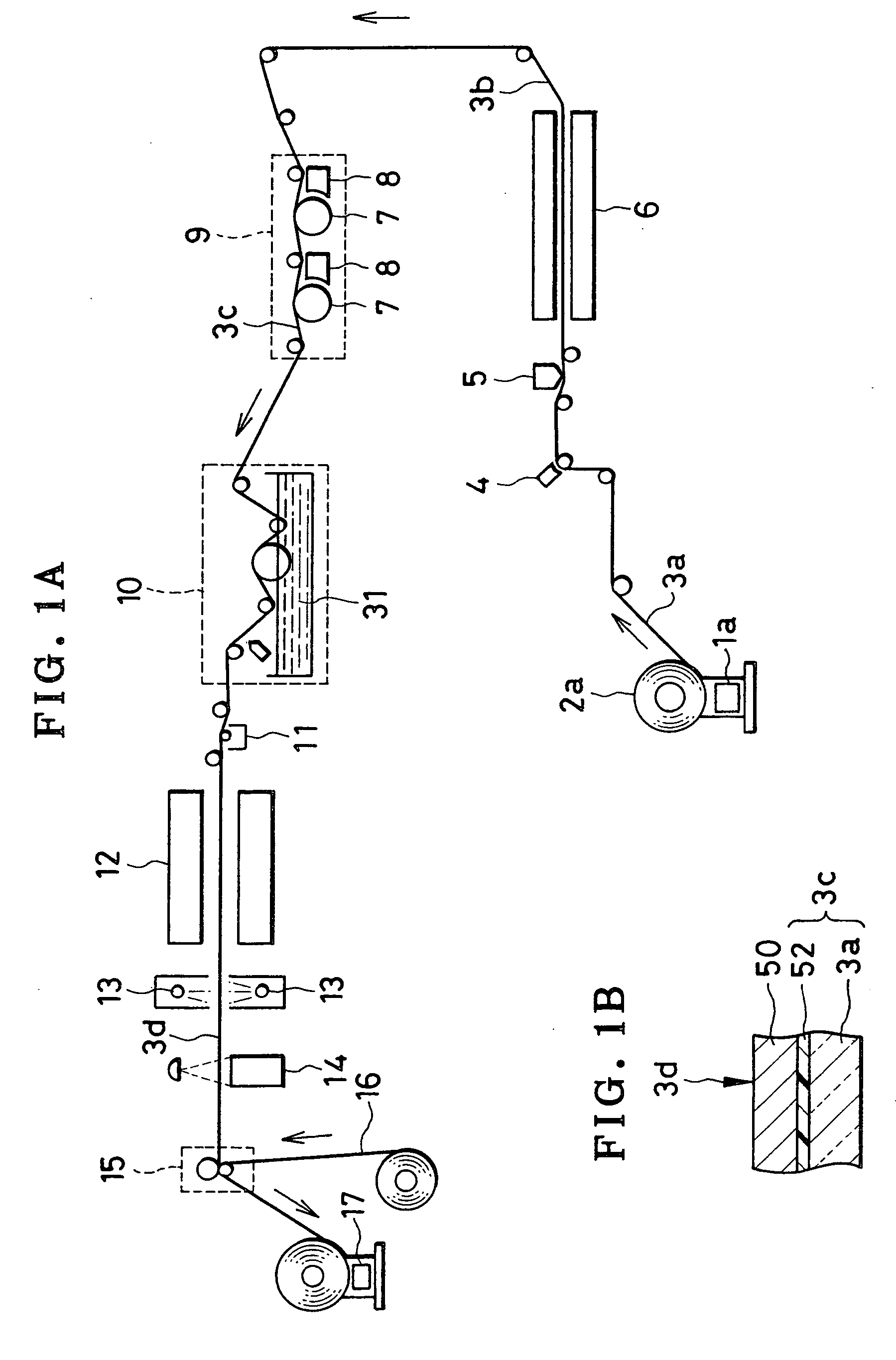

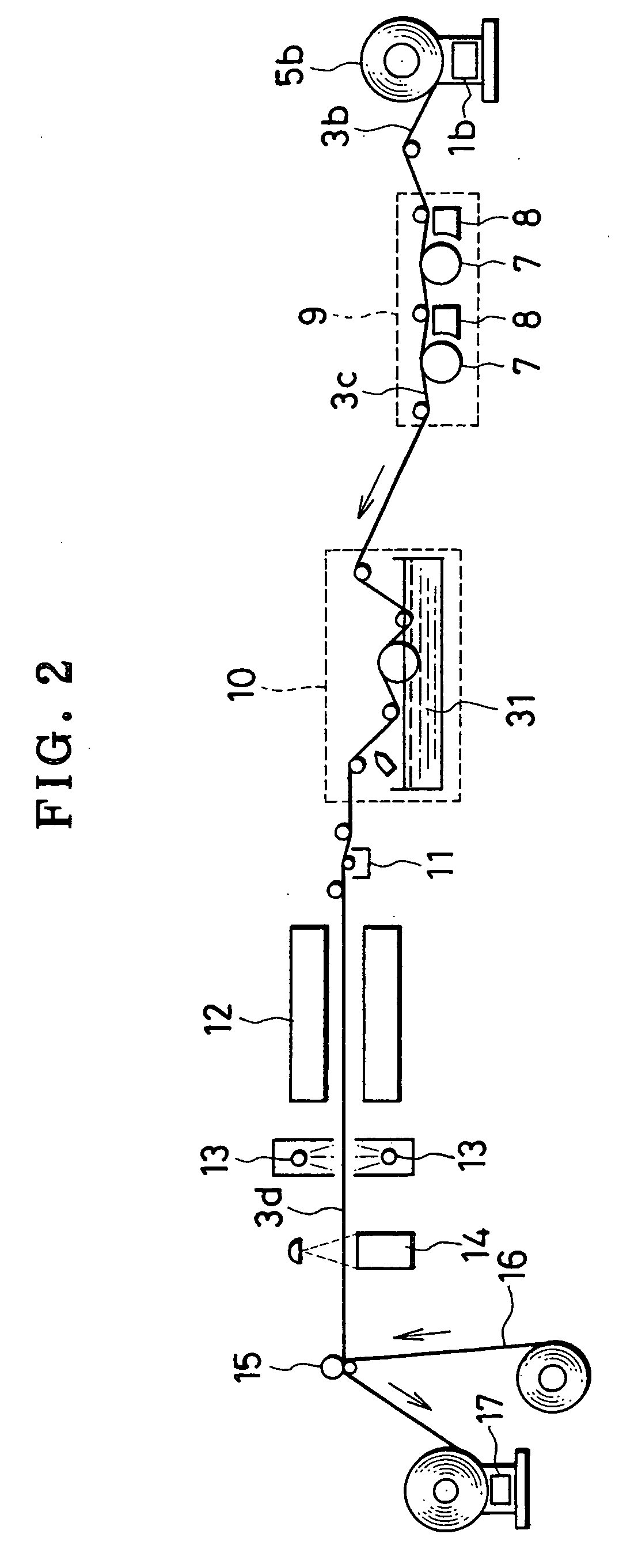

Method used

Image

Examples

examples

[0272] Comparative Example 6 (Prior Art)

[0273] In FIG. 16, a web supply device 201 supplied polyethylene terephthalate film at a speed of 50 m / min. The film was 100 μm thick and 100 cm wide. A coater head 202 coated the film with coating solution including particles of latex of which average diameters were 3 μm and 10 μm. A drier zone 203 evaporated the coating solution to obtain film in which an amount of deposited foreign matter was controlled. Composition of the coating solution including the latex was as follows:

3 μm latex stock solution0.1 ml10 μm latex stock solution3.0 mlMethanol46.9 ml Pure water50.0 ml

[0274] The latex stock solution includes monodisperse polystyrene latex at 1 wt. %. The resin film 210 was coated with the solution at 25 ml / m2. A surface of the resin film 210 was dried, and then checked visually through a microscope. It was observed that latex particles of 3 μm and 10 μm were regularly deposited on the surface at a density of approximately 1,000 particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com