Pulper device for the recovery of paper production waste, plant comprising said device and associated method for recovery of the waste

a technology of paper production waste and pulverizer, which is applied in the field of pulverizing device for the recovery of paper production waste, can solve the problems of serious danger, cutting of the web, and production waste around the machine, and achieves the effect of suitable recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

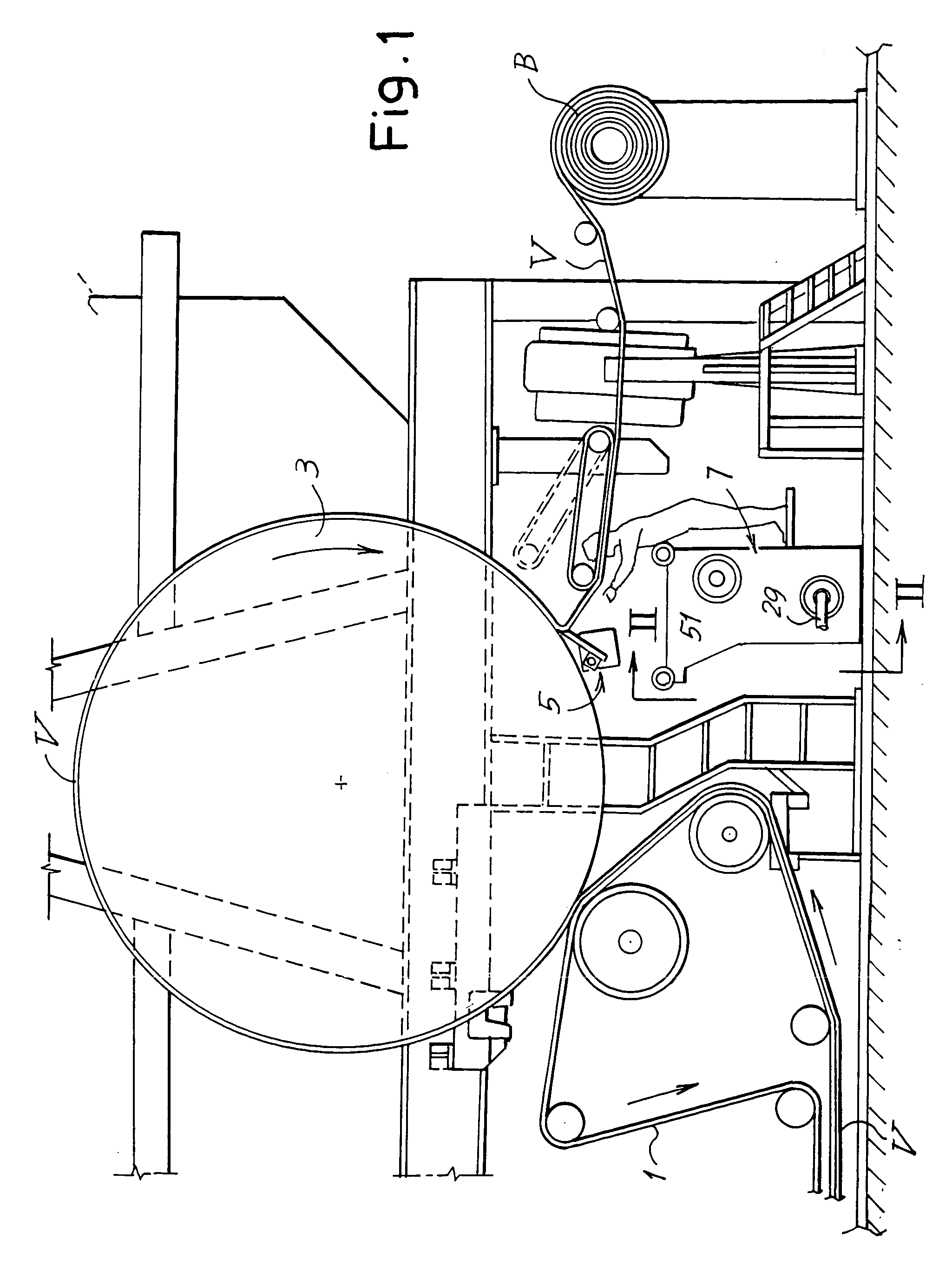

[0034] FIG. 1 illustrates schematically the terminal part of the line for the production of a web or strip of paper, in particular tissue paper. 1 denotes the last wire or the last felt for conveying the partially dried layer of slurry formed in a manner known per se. The felt 1 is tangential to a yankee drier 3 so as to transfer the moist web from the external surface of the felt to the external cylindrical surface of the yankee drier 3 which is heated internally. The yankee drier 3 is embraced by the web over a wide contact arc, between the zone of tangential contact with the felt 1 and a doctor or separator blade 5. In a manner known per se the web V, which is dried owing to the heat exchange with the yankee drier 3, is separated from the cylinder and wound so as to form a reel B intended for further processing.

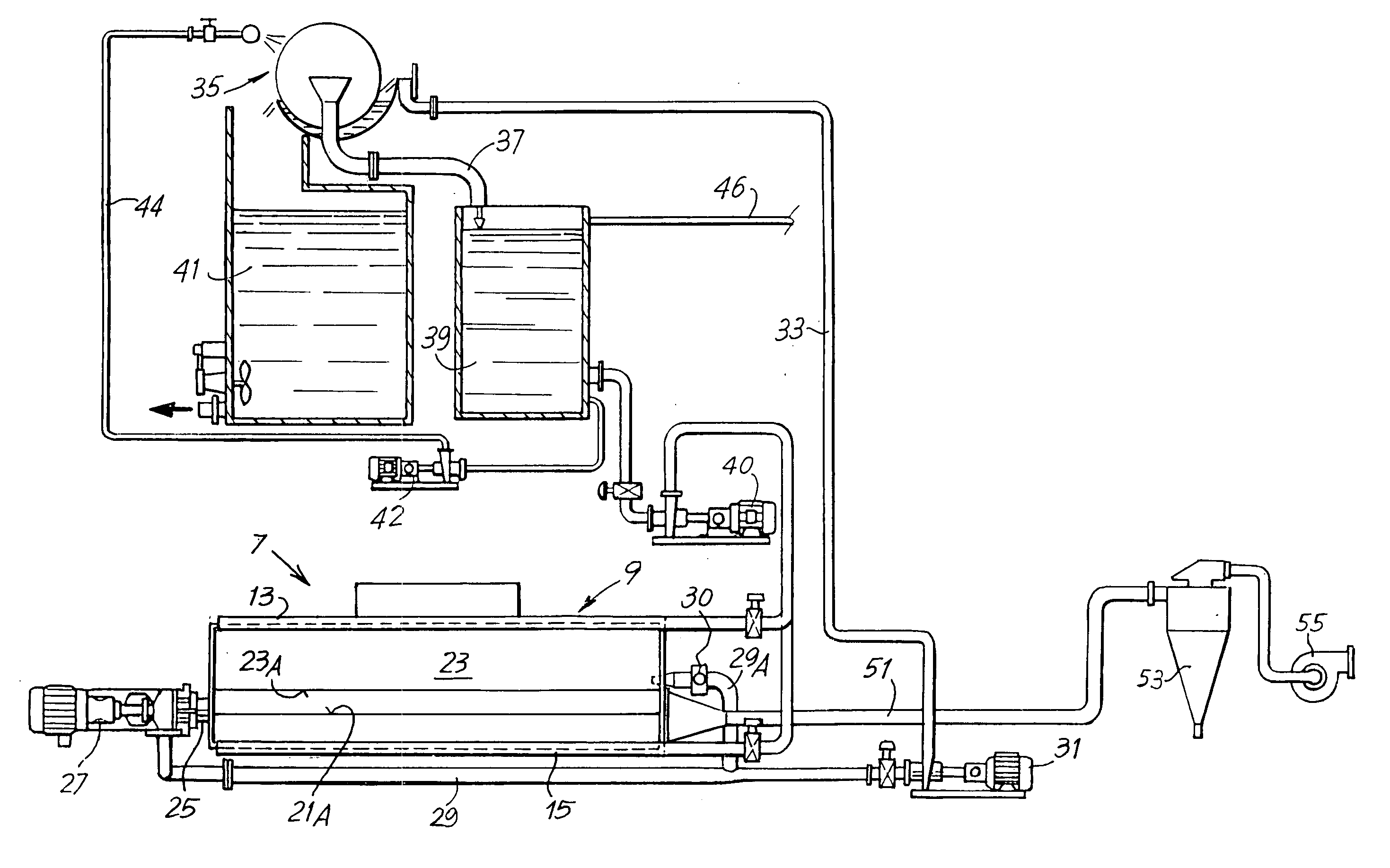

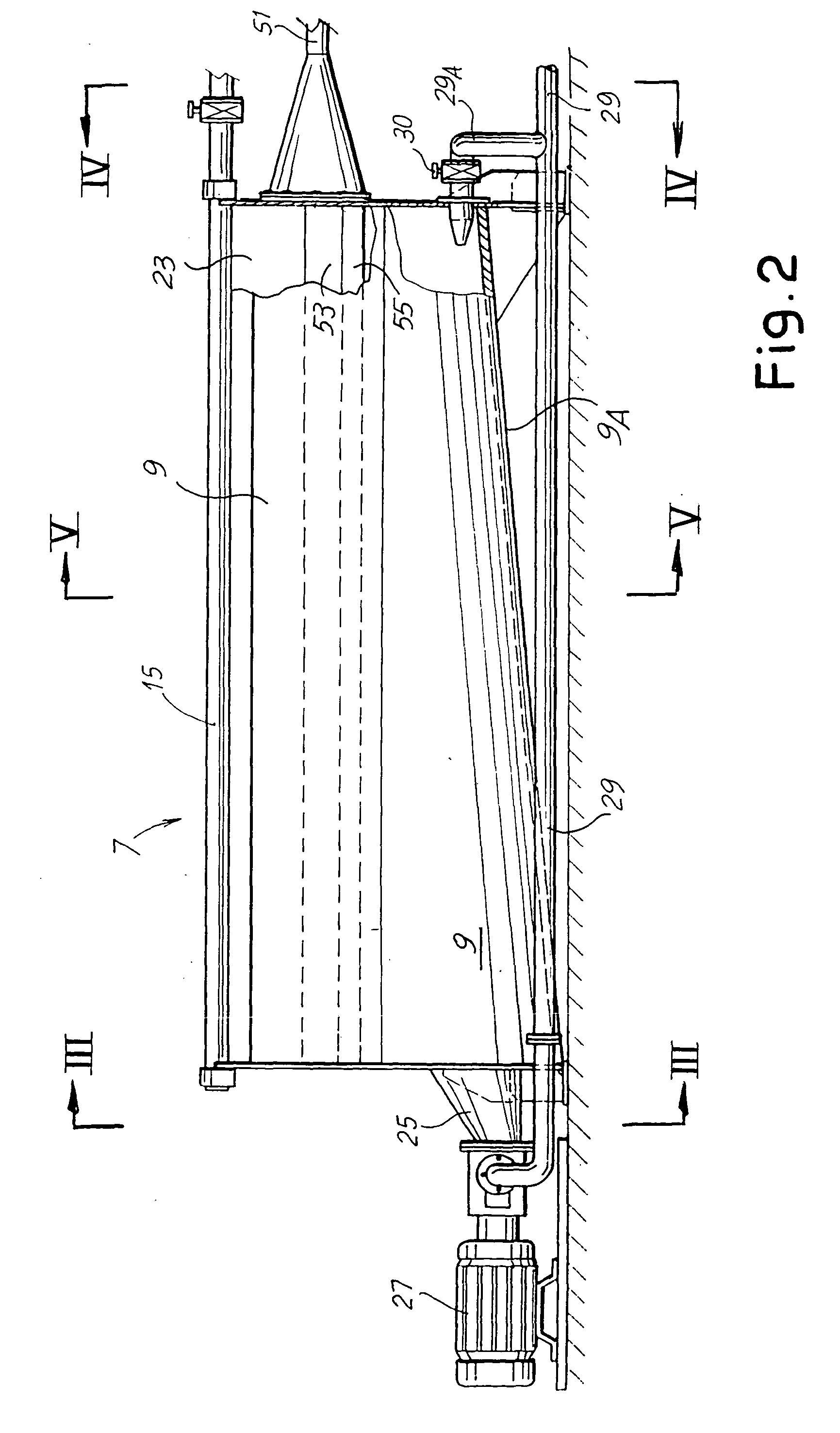

[0035] Below the yankee drier 3, and in particular in the zone where the doctor blade 5 is arranged, there is a device 7 for collection and recovery of the waste or scrap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com