A method for soil improvement of a mixture of industrial solid waste and sludge using modified montmorillonite

A technology of montmorillonite and montmorillonite, applied in the field of modified montmorillonite products and its preparation, can solve the problems of difficult harmless treatment, low comprehensive utilization rate of Dianchi dredged sediment, and reduce leaching loss , promote healthy development, and solve problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

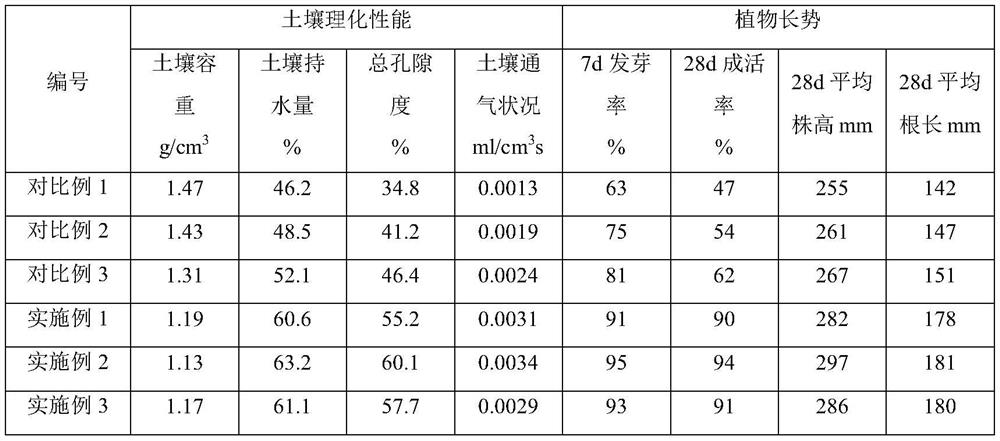

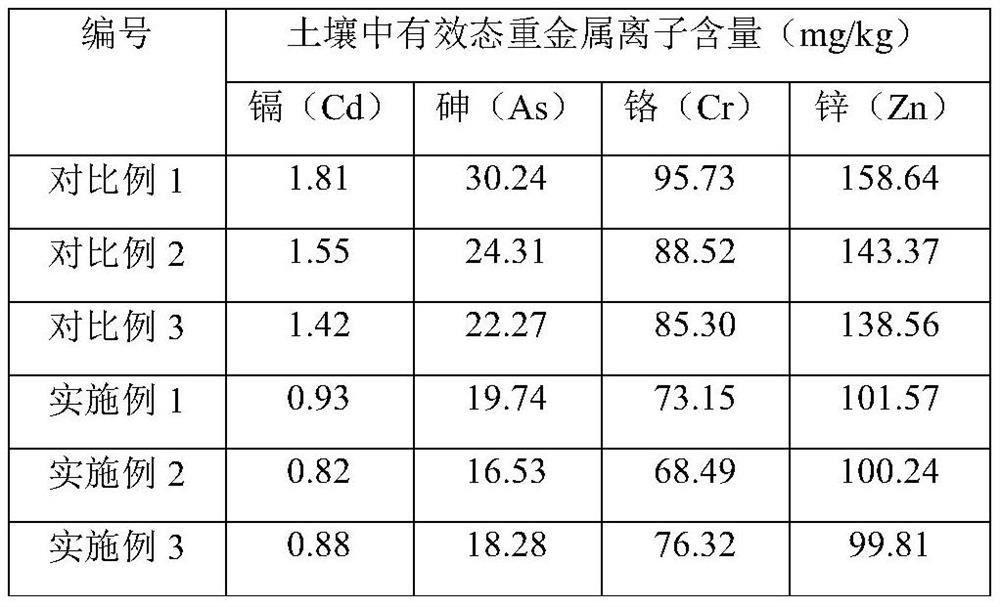

Examples

Embodiment 1

[0032] (1) Preparation of modified montmorillonite

[0033] Take 3 parts of ethylenediaminetetraacetic acid, 2 parts of diethanolamine, 0.4 part of Wenlun rubber, 44.6 parts of montmorillonite, and add 50 parts of water to stir in order according to the number of parts by mass. The temperature is controlled at 55 °C and the reaction time is 2 hours to obtain the modified montmorillonite. off the soil.

[0034] (2) Take 5 parts of modified montmorillonite, 48 parts of Dianchi dredged sediment, and 38 parts of phosphogypsum in sequence according to the parts by mass, and mix and stir evenly.

[0035] (3) Add 9 parts of carbide slag to the step (2) in parts by mass, stir and mix evenly, and adjust the pH value of the mixture to 6.8.

[0036] (4) The mixture obtained in step (3) is stored and aged for 4 months under natural conditions to obtain black gray soil.

Embodiment 2

[0038] (1) Preparation of modified montmorillonite

[0039] Take 5 parts of ethylenediaminetetraacetic acid, 6 parts of diethanolamine, 0.2 part of Wenlun rubber, 38.8 parts of montmorillonite and add 50 parts of water to stir in order according to the number of parts by mass. The temperature is controlled at 40 °C and the reaction time is 1.5 hours to obtain the modified Montmorillonite.

[0040] (2) Take 8 parts of modified montmorillonite, 34 parts of Dianchi dredged sediment, and 46 parts of phosphogypsum in sequence according to the parts by mass, and mix and stir evenly.

[0041] (3) Add 12 parts of carbide slag to the step (2) in parts by mass, stir and mix evenly, and adjust the pH value of the mixture to 7.2.

[0042] (4) The mixture obtained in step (3) is stored and aged for 6 months under natural conditions to obtain black gray soil.

Embodiment 3

[0044] (1) Preparation of modified montmorillonite

[0045] Take 4 parts of ethylenediaminetetraacetic acid, 5 parts of diethanolamine, 0.3 part of Wenlun rubber, 40.7 parts of montmorillonite and add 50 parts of water to stir in order according to the number of parts by mass. The temperature is controlled at 60 °C and the reaction time is 1 hour to obtain the modified montmorillonite. off the soil.

[0046] (2) Take 6 parts of modified montmorillonite, 42 parts of Dianchi dredged sediment, and 42 parts of phosphogypsum in sequence according to the parts by mass, and mix and stir evenly.

[0047] (3) Add 10 parts of carbide slag to the step (2) in parts by mass, stir and mix evenly, and adjust the pH value of the mixture to 7.5.

[0048] (4) The mixture obtained in step (3) was stored and aged for 3 months under natural conditions to obtain black gray soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com