Reduced density foam articles and process for making

a foam article and density reduction technology, applied in the field of reduced density foam articles, to achieve the effect of further reducing the density of the foam articl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 3

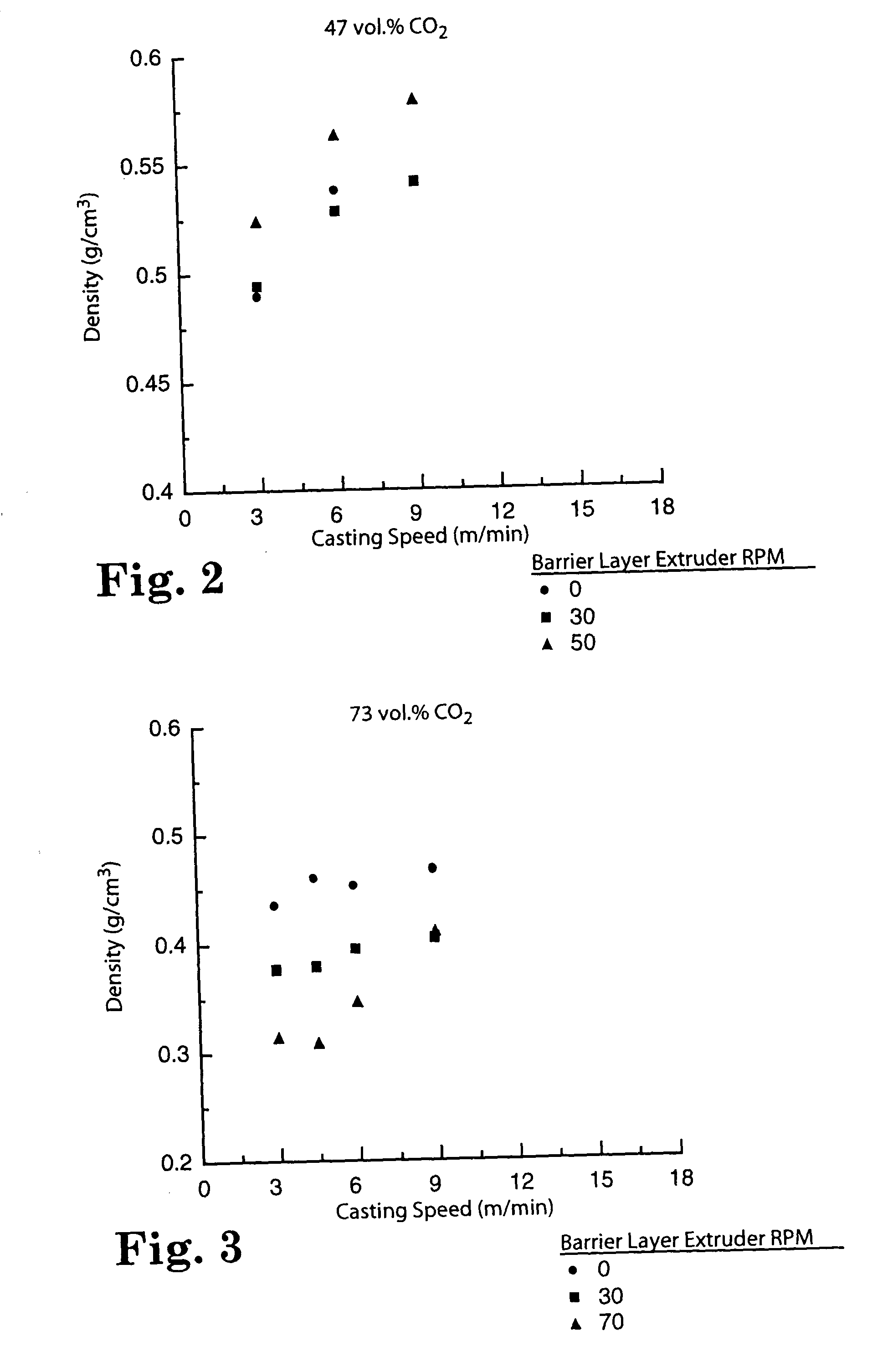

[0110] The foam articles of this example were made with a foamable layer having a gas concentration of about 73.0 volume percent.

[0111] The foam articles of Example 3 were made and tested in the same manner as those in Comparative Example 1 except that 6 wt % RIC-50 was used as a blowing agent, and the screw RPM of extruder 24 and the line speed were different. Operating conditions and test results are shown in Table 3.

[0112] Surprisingly, the data in Table 3 show that, for these ABA foam articles made with a 73.0% vol. CO.sub.2 fugitive gas concentration in the B layer, at a given casting speed, density decreased as barrier layer thickness increased. The data in Table 3 are shown graphically in FIG. 3.

3 TABLE 3 A Layer Final Material FinalTotal B Layer Thick- Flow- Casting Thick-RIC-50 CO.sub.2 T.sub.m P.sub.m Gas ness rate Speed Density ness Example Wt % wt % .degree. C. MPa vol % Mat'l RPM .mu.m kg / hr m / min g / cm.sup.3 .mu.m 3A 6.0 none 173 14.9 73.0 None 0 0 13.9 3.0 0.43 830 3B ...

example 4

[0113] The foam articles of this example were made with a foamable layer having a gas concentration of about 90.0 volume percent.

[0114] The foam articles of Example 4 were made in the same manner as those in Comparative Example 1 except that a combination of 1.6 wt % carbon dioxide and 2 wt % RIC-50 were used as blowing agents, and the screw RPM of extruder 24 and the speed of casting drum 28 were different. The carbon dioxide gas (99.9%, Oxygen Services, St. Paul, Minn.) was introduced into extruder 14 at 0.23 kg / hr (0.5 lb / hr). Operating conditions and test results are shown in Table 4.

[0115] As the data in Table 4 show, for these ABA foam articles made with a 90.0% vol. CO.sub.2 fugitive gas concentration in the B layer, at a given casting speed, as barrier layer thickness increased foam density decreased by between 5 and 60%. For example, comparison of Examples 4A and 41 shows that adding a barrier layer having a final thickness of 84.3 .mu.m decreased foam density by almost 60%...

example 6

[0120] The foam articles of this example were made with barrier layers comprising a pressure sensitive adhesive KRATON available as HL2642X from H.B. Fuller, St. Paul, Minn., and a foamable layer having a gas volume concentrations of 90 vol. %.

[0121] The foam articles of Example 6 were made in the same manner as those in Comparative Example 5 except that a different blowing agent formulation was used. The blowing agent used was 2 weight % RIC-50 and 1.6 weight % CO.sub.2. Operating conditions and test results are shown in Table 6. Some of the data in Table 6 are shown in FIG. 6. Data for Examples 4B, 4C, and 4D, which were made using a similar gas volume percent are also shown in Table 6 for comparative purposes.

[0122] As the data in Table 6 shows, for these ABA foam articles made with a 90.0% vol. CO.sub.2 fugitive gas concentration in the B layer, at a given casting speed, foam density decreased as barrier layer thickness increased. For example, as shown by comparing 4D and 6F, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling points | aaaaa | aaaaa |

| boiling points | aaaaa | aaaaa |

| boiling points | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com