Displacement type compressor and method of forming coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

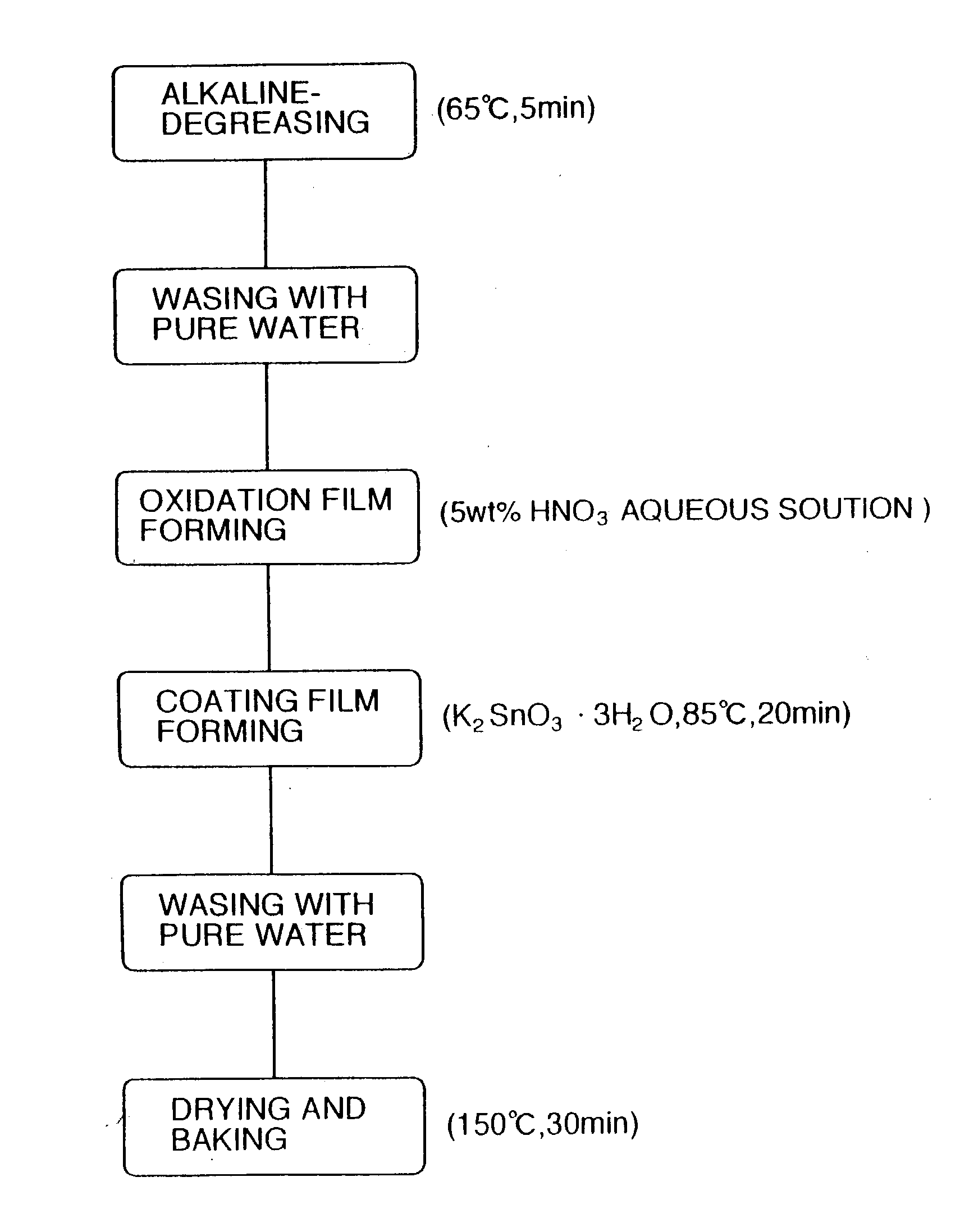

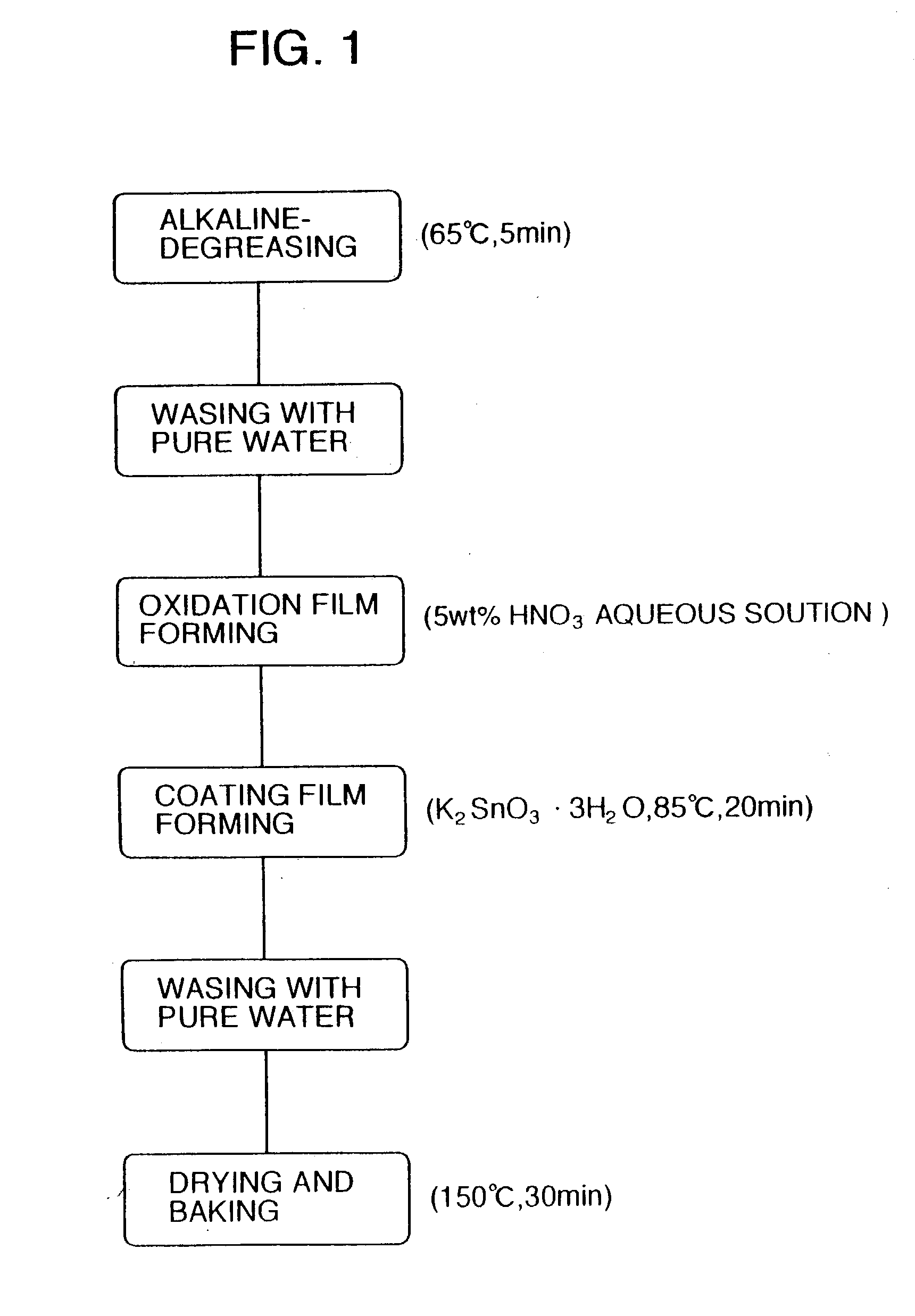

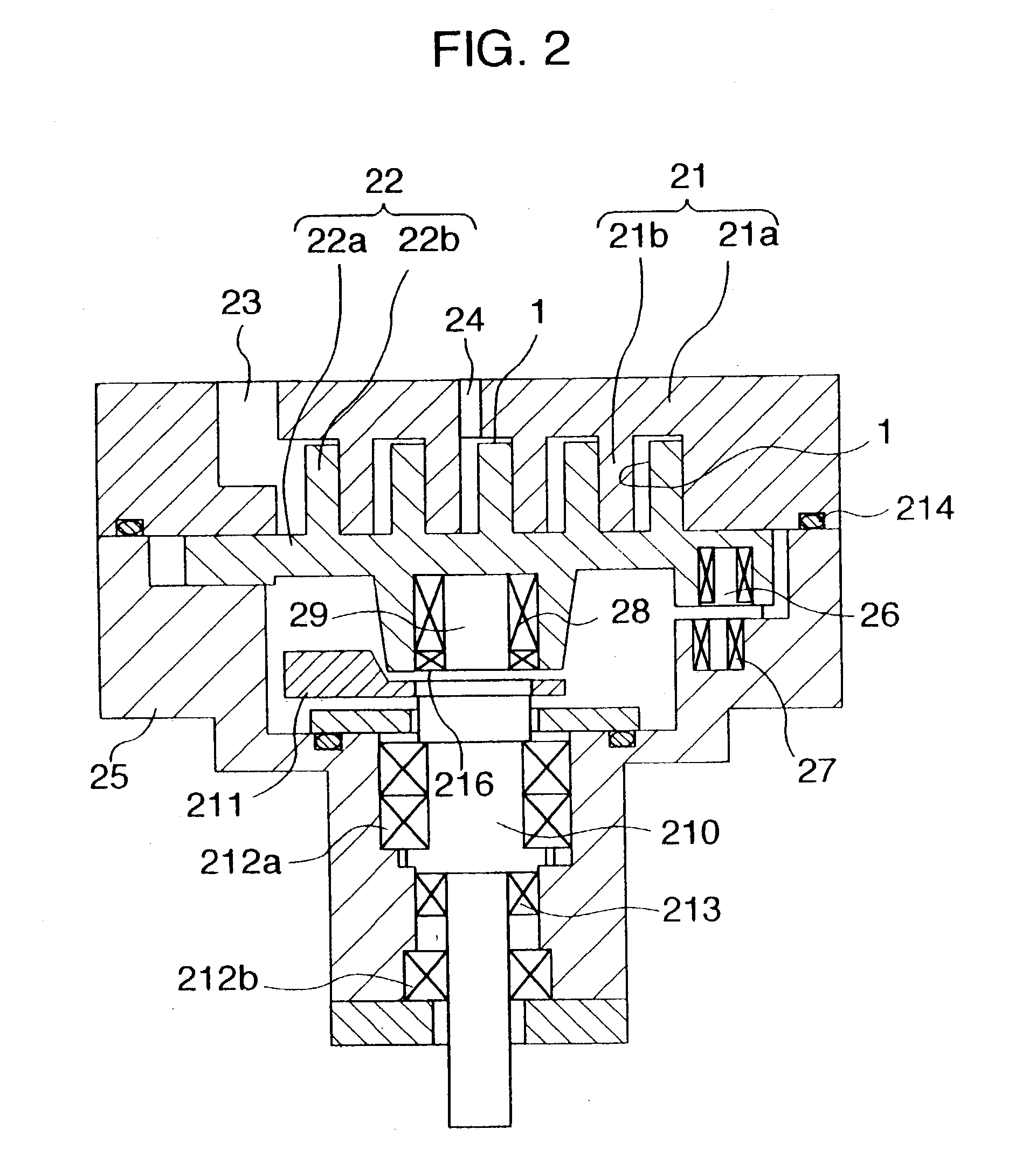

[0022] Explanation will be made of embodiments of the present invention with reference to FIGS. 1 to 4.

[0023] FIG. 1 shows a coating process according to the present invention. An FC250 member to be formed with a tin compound coating film is at first washed through alkaline-degreasing (using degreasing liquid FC315 made of Nihon Parkerizing Co., for 5 minutes at a temperature of 65 deg. C.), and thereafter, it is washed with pure water. Then, the outer surface of the member is dipped in an aqueous solution containing 5 wt. % of nitric acid for 5 minutes after it is heated up to 30 deg. C., and after oxidation-etching, it is washed with a stream of ion-exchange water.

[0024] Thereafter, a stannate mixed solution composed of the following components, and the above-mentioned FC250 member to be processed is dipped in the mixed solution under such a condition such as a temperature of 85 deg. C. for 20 minutes, in order to form a stannate compound coating film.

1 Stannate Mixed Solution K.s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com