Shock absorbing material

a technology of shock absorption and material, applied in the direction of bumpers, magnetic bodies, machines/engines, etc., can solve the problems of difficult reduction of the thickness of the cross sectional shape, poor accuracy, and difference in the cooling rate along the cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0070] Al--Mg--Si series aluminum alloy billets of the chemical compositions shown in FIG. 1-1 were manufactured by melting by DC casting, and applied with a soaking treatment at 550.degree. C..times.4 hr. Successively, by conducting extrusion under the conditions of an extrusion temperature at 500.degree. C. and an extrusion rate of 5 m / min, and press quenching (blower air cooling (cooling rate: about 190.degree. C. / min)) at the position just after the extrusion to obtain an extrusion material of a hollow cross section as shown in FIG. 1 (70 mm for longer side, 50 mm for shorter side and 2 mm for thickness). Then, the extrusion material was applied with an aging treatment at 190.degree. C..times.3 hr to prepare test specimens. The thickness of the recrystallization layer from the outer surface and the inner surface at the central portion of the longer side and the shorter side for the cross section of the test specimen was measured to determine the thickness as an average value for...

example 2

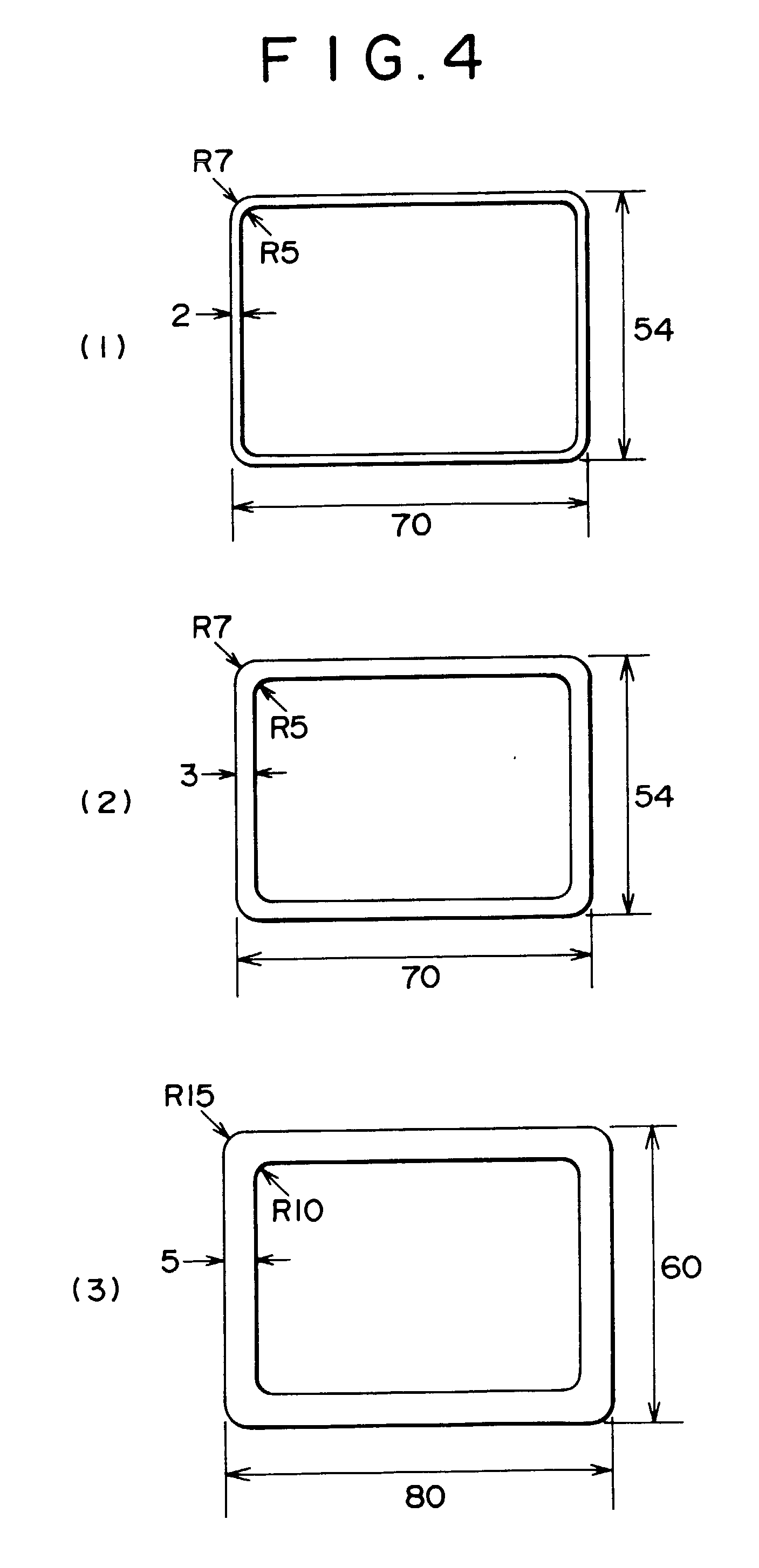

[0075] Al--Mg--Si series aluminum alloy billets of the chemical compositions shown in Table 2-1 were manufactured by melting by DC casting and applied with a soaking treatment at 550.degree. C..times.4 hr. Successively, extrusion was conducted at an extruding temperature of 500.degree. C. and at a extruding rate shown in Table 1, and air cooled or water cooled press quenching in on-line was applied just after extrusion to obtain extrusion materials each of a hollow rectangular cross section as shown in FIG. 4 (having 70-80 mm long or side, 54-60 mm shorter side and 2-5 mm thickness). Air cooling was applied by a blower air cooling at a cooling rate of about 190.degree. C. / min, whereas water cooling was applied at a cooling rate of about 10000.degree. C. / min. Then, an aging treatment at 190.degree. C. for 3 hours was applied to the extrusion materials to obtain test materials.

[0076] For the test materials, thickness of the surface recrystallization layer (GG layer), crystal grain siz...

example 3

[0090] The example of the present invention is to be explained in comparison with a comparative example out of the definition for the scope of the claims of the present invention.

[0091] At first, Al--Mg--Si series aluminum alloy billets (diameter: 155 mm) of the chemical composition shown in the following Table 3-1 were manufactured by melting by the usual method and a homogenizing treatment was applied under the condition of about 540.degree. C..times.4 hours.

[0092] Then, each of the billets was subjected to extrusion under the conditions at an extrusion temperature of 500.degree. C. and an extrusion rate of 5 m / min, air cooled or water cooled press quenching was conducted on-line just after extrusion to manufacture extrusion materials each of hollow square cross section as shown in FIG. 4-(1) (a square pipe having an outer shape of 70.times.54 mm and a thickness of 2 mm). An artificial aging treatment was applied under the conditions shown in Table 3-1 to prepare test materials.

5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com