Hydrogel thin film containing extracellular matrix components

a technology of extracellular matrix and hydrogel, which is applied in the field of hydrogel thin film containing extracellular matrix components, can solve the problems of difficult handling of collagen hydrogel itself, difficult preparation of cell culture substratum, and more simple utilization methods, so as to achieve convenient preparation for culturing, appropriate elastic strength, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Collagen Hydrogel Thin Film

[0032] 2 ml of quintuple-concentration Dulbecco's Modified Eagle Medium (GIBCO #31600-034), 0.1 ml of 10,000 units / ml penicillin and 10,000 .mu.g / ml streptomycin (GIBCO #15140-031), 0.2 ml of 1M HEPES (GIBCO #15630-023), 0.493 ml of 7.5% sodium bicarbonate solution (GIBCO #25080-011), 1.407 ml of distilled water, and 1 ml of fetal bovine serum were Put in a sterilized conical tube (Falcon #2070) chilled on ice, having an inner volume of 50 ml, and mixed. Then 4.8 ml of 0.5% aqueous type-I collagen solution (CELLGEN I-AC or I-PC, made by Koken Company) was added into the tube and uniformly mixed. After placing 2 ml of the mixed collagen solution having a final concentration of 0.24% in a culture dish made of hydrophobic Polystyrene (.O slashed.35 mm: Falcon #1008), the solution was held in a humidified incubator at 37.degree. C. in the presence of 5% CO.sub.2 / 95% air in 3 hours for its gelation. This collagen gel of the final concentration of...

example 2

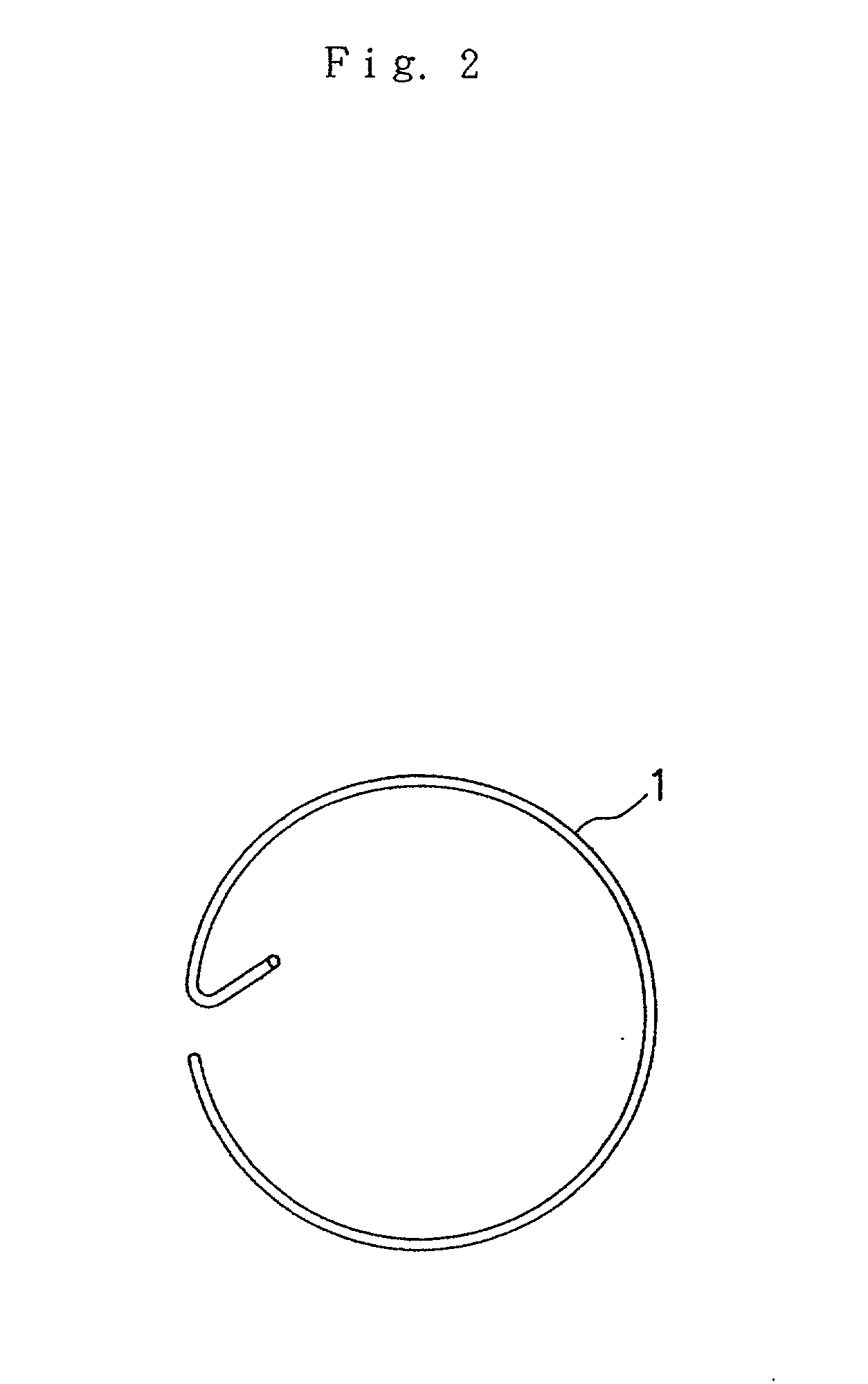

Preparation of Collagen Hydrogel Thin-film with Peripheral Wire Retainer

[0033] A circular retainer (1) with a knob as shown in FIG. 2 was made with a stainless steel wire (size: #20; 0.9 mm), and 2 ml of the mixed collagen solution having a final concentration of 0.24% prepared in Example 1 was placed, together with this wire retainer, into a hydrophobic polystyrene culture dish (.O slashed.35 mm; Falcon #1008). In the same manner as in example 1, the collagen solution with the retainer was vitrified after its glation. The vitrified collagen gel was hydrated by adding 2 ml PBS. Further, the collagen gel thus hydrated was rinsed several times with 2 ml of PBS. The hydrated collagen gel could be peeled off and collected from the dish by slowly lifting the stainless steel knob, in the form of a thin-film collagen hydrogel having a satisfactory elastic strength with a wire retainer surround it as shown in FIG. 3.

example 3

Preparation of Gauze Embedding Type Collagen Hydrogel Thin Film

[0034] A sterilized type-III gauze as prescribed in the Japanese Pharmacopoeia (K-Pine made by, Kawamoto Hotai Zairyou Company) was cut in a circular shape with a knob in an aseptic manner, and immersed the cut gauze in a cell culture medium (Dulbecco's Modified Eagle Medium containing 10% fetal bovine serum, 20 mM HEPES, 100 units / ml penicillin and 100 .mu.g / ml streptomycin). The gauze was put, together with 5 ml of the mixed collagen solution having a final concentration of 0.24% prepared in Example 1, in a hydrophobic polystyrene culture dish (.O slashed. 60 mm; Falcon #1007). In the same manner as in example 1, the collagen solution with the gauze was vitrified after its gelation.

[0035] Furthermore, the vitrified collagen gel was hydrated by adding PBS in the same manner as in Example 1. The hydrated collagen gel could be peeled off and collected from the dish by slowly lifting the knob of the gauze, in the form of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner volume | aaaaa | aaaaa |

| inner volume | aaaaa | aaaaa |

| inner volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com