Viscoelastic mud as well as preparation method and application thereof

A viscoelastic, elastomeric technology, applied in applications, food science, chewing gum, etc., that can solve problems such as poor viscosity and rebound rate, application limitations, lack of tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Such as figure 1 As shown, the preparation method of viscoelastic slime in one embodiment is a preparation method of the above-mentioned viscoelastic slime. The preparation method of this viscoelastic mud comprises the steps:

[0036]Step S110: Weighing the raw materials, in terms of mass percentage, the raw materials include: 4%-20% elastomer, 0%-40% softening oil and 40%-96% liquid rubber.

[0037] Among them, the elastomer is in the form of granules or powder or indeterminate bulk. The elastomer is selected from at least one of styrene-based block copolymers and semi-solid polyisobutylene rubber. Specifically, the styrenic block copolymer is selected from styrene-butadiene-styrene block copolymer (SBS), styrene-isoprene-styrene block copolymer (SIS), styrene- Ethylene-butylene-styrene block copolymer (SEBS), styrene-ethylene-propylene-styrene block copolymer (SEPS) and hydrogenated styrene-butadiene-isoprene-styrene block copolymer At least one of the substances ...

Embodiment 1

[0058] The preparation process of the viscoelastic mud of embodiment 1 and embodiment 10~22 is as follows:

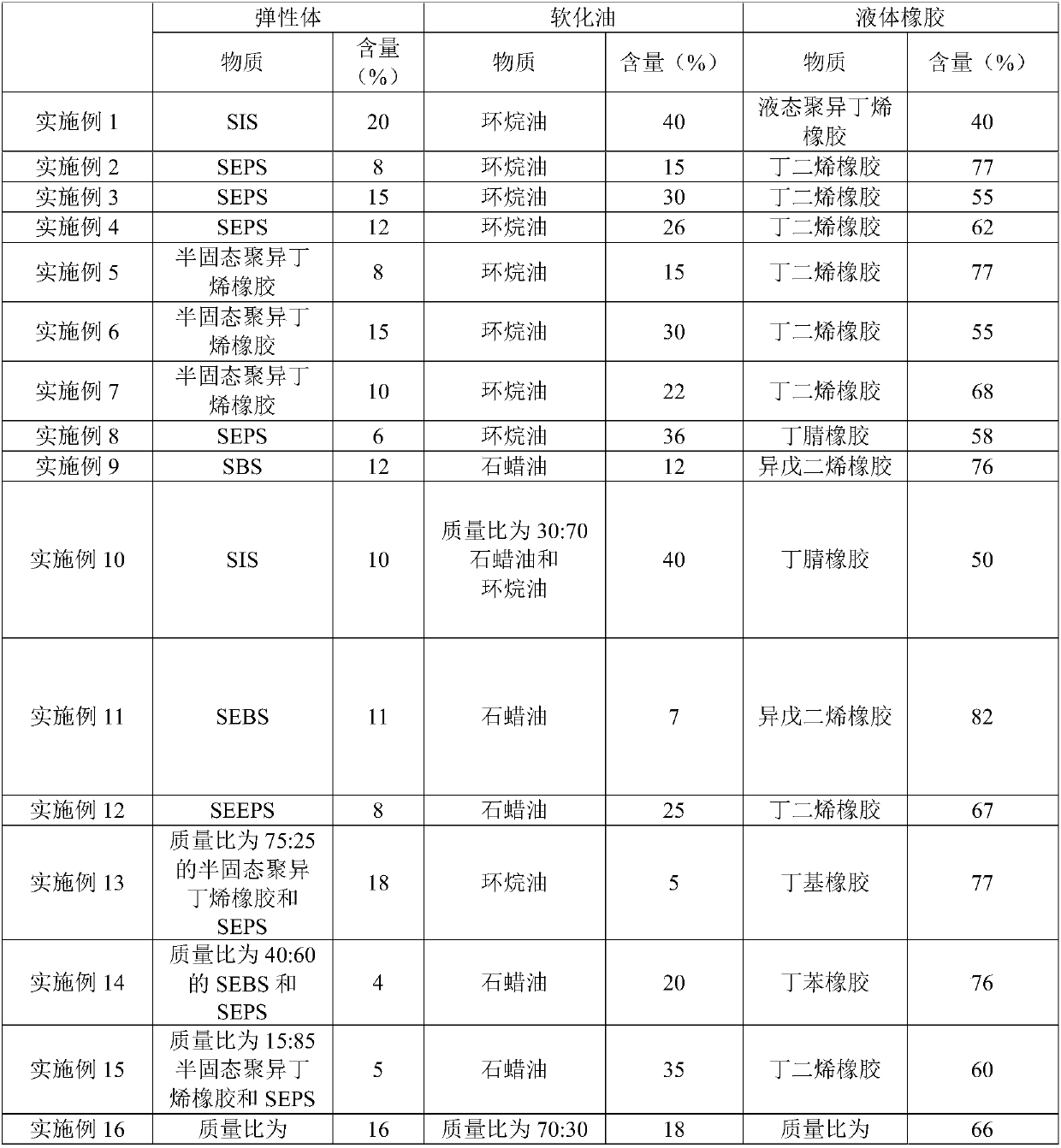

[0059] (1) Weigh each component according to Table 1 to obtain raw materials. Wherein, the content in Table 1 represents the mass percentage content of each component.

[0060] (2) Under the condition of room temperature and continuous stirring, the softened oil and the liquid rubber were evenly mixed, then the elastomer was added and the mixture was continued for 35 minutes to obtain a mixture.

[0061] (3) The mixture was melted at 160° C. for 3 hours, and then cooled to obtain viscoelastic slime.

[0062] Table 1

[0063]

[0064]

Embodiment 2

[0066] The preparation process of the viscoelastic mud of the present embodiment is as follows:

[0067] (1) Weigh each component according to Table 1 to obtain raw materials. Wherein, the content in Table 1 represents the mass percentage content of each component.

[0068] (2) Under the condition of room temperature and continuous stirring, the softened oil and the liquid rubber were evenly mixed, and then the elastomer was added and mixed for 15 minutes to obtain a mixture.

[0069] (3) The mixture was melted at 120° C. for 6 hours, and then cooled to obtain viscoelastic slime.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com